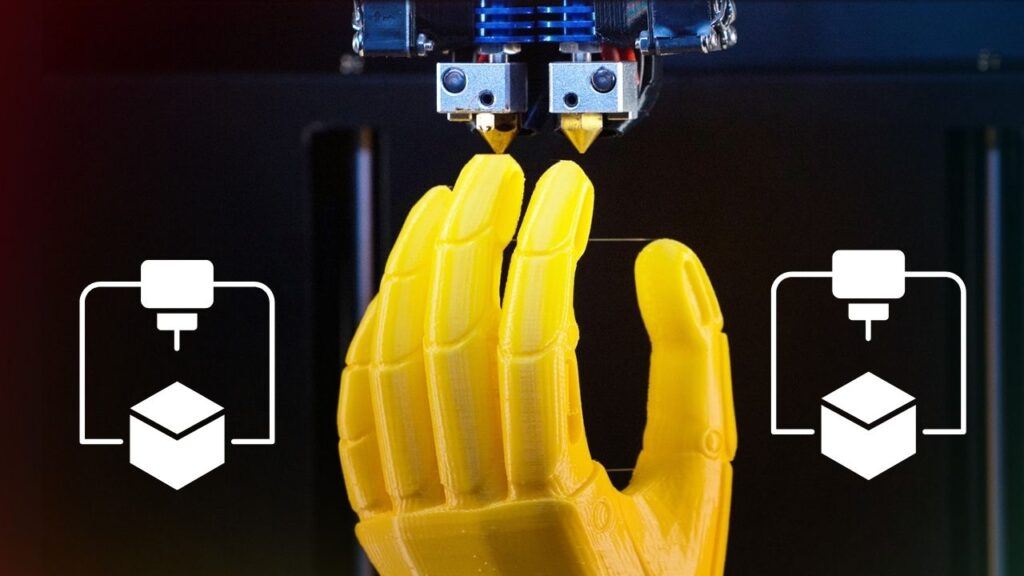

Advancements in 3D Printing: In recent years, advancements in 3D printing have radically reshaped how we design, prototype, and manufacture everything from intricate medical devices to entire buildings. But what’s pushing this innovation beyond its early limitations? It’s not just the printers themselves—it’s the new generation of materials powering them. These cutting-edge compounds are opening up a world of opportunities across industries like aerospace, automotive, healthcare, construction, and fashion, enabling designs that were previously impossible.

Whether you’re a curious beginner, a small business owner, or a seasoned engineer, understanding how material science is revolutionizing 3D printing is essential for staying ahead in today’s fast-evolving manufacturing ecosystem. In this expanded guide, we’ll explore the materials making waves, the industries being transformed, and how you can tap into the potential of next-gen 3D printing.

Table of Contents

Advancements in 3D Printing

| Feature | Details |

|---|---|

| Main Advancement | Introduction of new high-performance materials in 3D printing |

| Key Industries Impacted | Aerospace, Automotive, Healthcare, Construction, Fashion |

| Examples of New Materials | High-temp thermoplastics, composites, metal alloys, ceramics, biodegradable polymers |

| Emerging Trends | 4D printing, multi-material printing, sustainable bioplastics |

| Reference Website | Raise3D Blog |

The real revolution in 3D printing lies not only in faster machines but in intelligent, adaptive, and sustainable materials that meet the demands of modern industry. From life-saving medical implants to ultra-light aerospace components, new materials are turning imagination into reality.

For engineers, designers, and innovators, embracing these materials now will give you a competitive edge in tomorrow’s market. And for beginners, learning the basics of material capabilities is the best first step in this transformative journey.

Why Materials Matter in 3D Printing

Initially, 3D printing was largely limited to basic plastics like PLA (polylactic acid) and ABS (acrylonitrile butadiene styrene)—suitable for hobbyists and rough prototypes but lacking the durability, heat resistance, and mechanical properties needed for industrial use.

Today, thanks to breakthroughs in material science and chemical engineering, 3D printers can utilize a wide variety of functional, strong, and even medical-grade substances. This evolution means 3D-printed parts are now suitable for end-use production, not just visual models or test parts. In fact, entire supply chains are adapting to accommodate this digital transformation.

Exploring the Latest 3D Printing Materials

High-Performance Thermoplastics

PEEK (polyether ether ketone) and ULTEM (polyetherimide) are considered premium thermoplastics due to their exceptional strength, heat resistance, and chemical stability. These materials are often used in aerospace interiors and sterilizable surgical instruments because they maintain their properties in extreme conditions.

Fact: According to Prototal, these high-grade thermoplastics are increasingly replacing metals in critical applications due to their weight savings and process flexibility.

Composite Filaments

By integrating fibers such as carbon, glass, or Kevlar into traditional plastics, composite filaments offer significantly enhanced mechanical strength without adding substantial weight. These are particularly useful in sectors like automotive and sports equipment, where lightweight strength is critical.

Example: Engineers at Ford have reduced component weight by 50% using carbon fiber-reinforced nylon.

Metal Printing Materials

3D printing isn’t limited to plastic. Today, metals like titanium, aluminum, stainless steel, and nickel superalloys are printed layer-by-layer in a process known as metal additive manufacturing. This allows manufacturers to create complex geometries that are impossible with traditional machining.

Stat: The global metal 3D printing market is expected to reach $25 billion by 2030, driven largely by aerospace and medical demand.

Ceramics

Though less common, ceramic materials like zirconia and silicon carbide are prized in electronics, aerospace, and dental industries for their heat resistance and wear durability. These are ideal for complex components exposed to harsh environments.

Biocompatible and Biodegradable Materials

For the healthcare and sustainability sectors, bioplastics and bioresins are becoming essential. PLA-based filaments are both safe for human contact and eco-friendly, making them perfect for temporary implants, packaging, or environmental monitoring devices.

Tip: Always verify FDA approval if using biocompatible materials in clinical or patient-facing applications.

Real-World Applications That Are Transforming Industries

Aerospace

Industry giants like Boeing, Airbus, and General Electric are pioneering the use of metal 3D printing for jet engine parts, cabin interiors, and drone components. These printed parts offer unprecedented weight reduction, leading to lower fuel consumption and emissions.

Highlight: GE’s 3D-printed fuel nozzles are five times more durable and 25% lighter than traditionally manufactured ones.

Automotive

Automakers such as BMW, Ford, and Porsche are leveraging 3D printing to produce custom tools, performance parts, and even production-grade components. Rapid prototyping also slashes development cycles from weeks to days.

Insight: Ford uses over 20 different 3D printing systems to enhance manufacturing efficiency across its global plants.

Healthcare

From custom prosthetics to bioprinted organs, the medical field is one of the most revolutionary users of 3D printing. Hospitals are producing patient-specific devices tailored from CT scans.

Stat: A 2023 study revealed a 70% clinical success rate for implantable 3D-printed devices, showcasing their reliability.

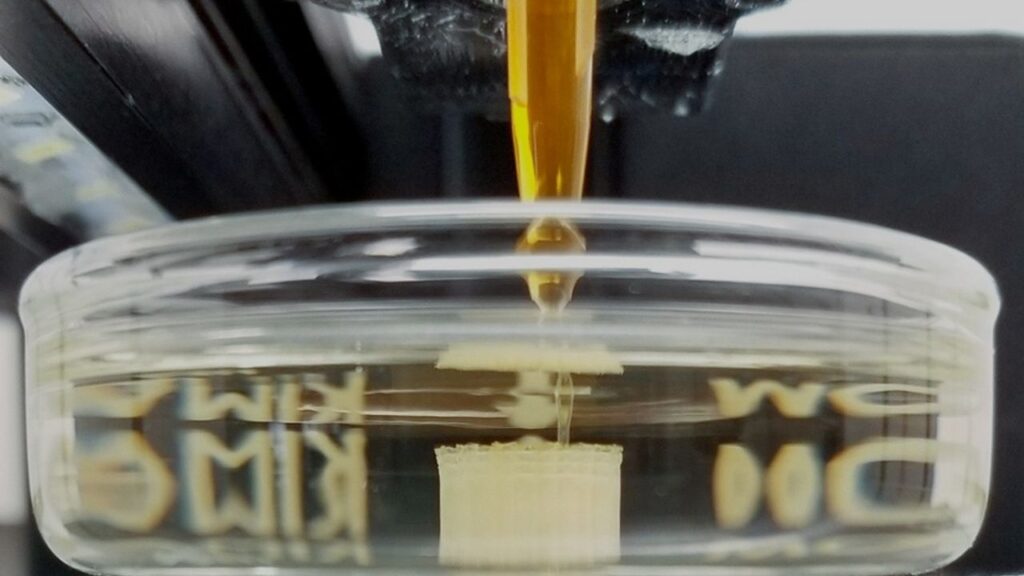

Construction

Yes, even entire homes and commercial structures are now being printed. Companies are using concrete-like pastes to extrude building layers with minimal waste and labor.

Example: Texas is home to the first 3D-printed hotel currently under construction, aiming to reduce build time and environmental impact.

Fashion & Consumer Products

Designers use 3D printing for customizable eyewear, athletic shoes, jewelry, and even handbags. This reduces inventory waste and allows for made-to-order manufacturing.

Trend: Adidas and Nike are experimenting with 3D-printed midsoles to tailor shock absorption to individual athletes.

Trends to Watch

Multi-Material and 4D Printing

Modern printers now support multi-material builds, allowing for complex components that combine flexible and rigid elements. 4D printing, which adds the element of time, enables materials to morph after printing in response to environmental conditions like temperature or moisture.

Use Case: In medicine, 4D-printed stents could expand inside the body without surgery.

Speed and Scalability

Technologies like HARP (High-Area Rapid Printing) and Continuous Liquid Interface Production (CLIP) dramatically improve print speeds while maintaining quality, making 3D printing viable for mass production.

Fact: HARP can print objects the size of a human in hours rather than days.

Sustainable Manufacturing

Companies are adopting closed-loop systems where materials are recycled post-use. With growing regulations on sustainability, 3D printing offers an advantage through localized, low-waste production.

Tip: Look for filaments made from recycled ocean plastics or bio-based resins to reduce your carbon footprint.

How to Get Started with Advanced 3D Printing Materials

Step 1: Define Your Application Needs

Clarify whether you need strength, flexibility, heat resistance, medical safety, or environmental sustainability. Your use case will dictate your material choice.

Step 2: Research and Choose Materials

Review datasheets and performance guides from trusted sources like Raise3D. Pay attention to tensile strength, elongation, thermal limits, and regulatory compliance.

Step 3: Match the Printer to the Material

High-performance materials often require special nozzles, enclosed chambers, or higher extrusion temperatures. Make sure your printer is compatible or consider upgrades.

Step 4: Perform Test Runs

Don’t go straight to full-scale production. Run tests to optimize print settings, such as temperature, speed, and layer height.

Step 5: Iterate and Improve

Analyze test results, make necessary adjustments, and repeat. The more you iterate, the better your final product will be.

LED Innovations: The Bright Future of Energy-Efficient Lighting

Is the Era of Silicon Coming to an End? What’s Next in Semiconductor Tech

FAQs About Advancements in 3D Printing

Q1: What is the most durable 3D printing material available?

A: PEEK, ULTEM, and carbon-fiber composites top the list, especially for high-stress applications in aerospace and automotive sectors.

Q2: Can I print metal at home?

A: Generally no. Metal 3D printing involves laser sintering and high-temperature handling, which is cost-prohibitive and unsafe for home environments.

Q3: Are biodegradable materials safe for medical use?

A: Yes, but only certain types. Always look for medical-grade certifications or FDA approval for biocompatibility.

Q4: What’s the cost of advanced 3D printing materials?

A: Costs vary widely. PLA is affordable (~$20/kg), but high-end materials like PEEK can exceed $500/kg depending on purity and supplier.

Q5: Can I mix materials in one print?

A: Yes, with a dual-extruder printer or multi-material setup. This allows you to combine rigidity and flexibility in one object.