Startup Uses Organic Electronics to Build Biodegradable Smart Sensors: In a world grappling with mounting e-waste and the urgent need for sustainable technologies, a new wave of innovation is emerging. One of the most promising developments in this space is the rise of biodegradable smart sensors—a solution powered by organic electronics. Startups around the globe are turning to eco-friendly materials to build high-tech sensors that naturally decompose after use, offering an exciting path forward for sustainable tech.

Not only do these biodegradable sensors promise to slash pollution and reduce landfill waste, but they also open the door to safer, more responsible use of electronics in everything from agriculture and healthcare to environmental monitoring.

Table of Contents

Startup Uses Organic Electronics to Build Biodegradable Smart Sensors

| Feature | Description |

|---|---|

| Technology | Organic electronics used to develop biodegradable smart sensors |

| Environmental Impact | Reduces electronic waste by decomposing naturally after use |

| Applications | Agriculture, healthcare, environmental monitoring |

| Example Use Case | Compostable soil sensors for digital agriculture |

| Notable Startups | Epishine AB, FlexEnable, PyrAmes |

| Official Resource | FlexEnable Official Site |

Biodegradable smart sensors represent a powerful intersection between sustainability and technology. Thanks to organic electronics, we’re entering an era where sensors don’t just collect data—they also vanish when their job is done, leaving no trace behind.

As more industries adopt these innovations, we’ll likely see an explosion of eco-friendly devices tailored for short-term use in healthcare, agriculture, and beyond. The journey toward a greener tech future has just begun—and these smart, earth-friendly sensors are leading the charge.

What Are Biodegradable Smart Sensors?

Biodegradable smart sensors are electronic devices made from organic, environmentally friendly materials that can perform specific sensing tasks and then naturally break down after their lifecycle ends. Unlike conventional electronics, which rely on toxic metals and plastics that linger in landfills, these sensors are crafted from materials like:

- Organic polymers

- Plant-based substrates

- Conductive biodegradable inks

These components make the sensors safe for composting or natural degradation, significantly reducing their impact on the planet.

Why Organic Electronics?

Organic electronics use carbon-based materials that can conduct electricity. Unlike silicon or metal components, these organic compounds can be printed onto flexible materials, making them ideal for wearable devices, smart packaging, and environmental monitors.

More importantly, organic electronics can be:

- Flexible and lightweight

- Cheaper to produce

- Environmentally friendly

The combination of low cost and sustainability makes them ideal for temporary or disposable applications—especially in sectors like agriculture or health monitoring, where short-term data collection is key.

Practical Examples in Action

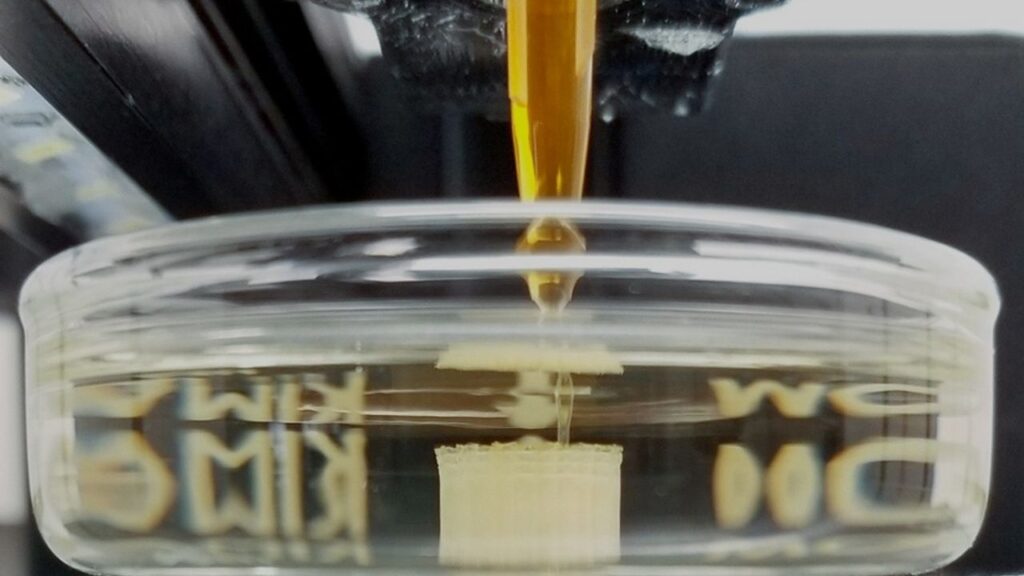

Compostable Soil Sensors

A team from the University of Glasgow, in partnership with Poland’s Lukasiewicz Research Network, has developed screen-printed soil sensors that degrade into compost. These sensors are designed to track moisture and nutrient levels in soil. Once their job is done, they can be tilled back into the earth, adding nutrients rather than waste.

Wearable Health Devices

Startups like PyrAmes are using biodegradable components to build e-skin sensors—flexible patches worn on the skin to monitor health metrics like heart rate and blood pressure. Once used, these e-skins can be safely discarded, eliminating medical e-waste.

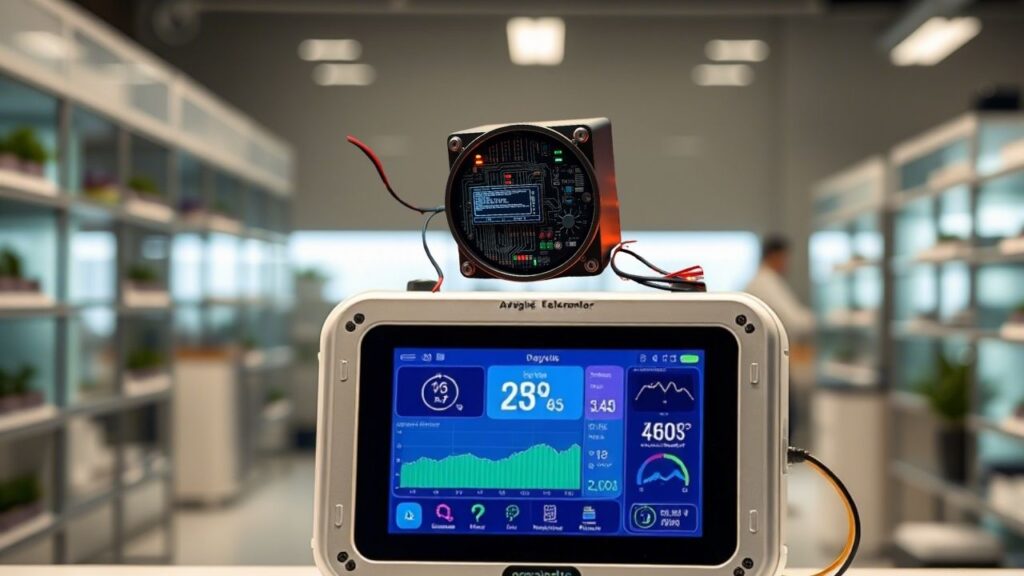

Environmental Monitoring

Imagine placing sensors in forests to monitor temperature and humidity, then letting nature absorb them. That’s exactly what companies like FlexEnable envision. These sensors work reliably for weeks or months, then dissolve harmlessly—leaving no ecological footprint.

How Do Biodegradable Sensors Work?

Step-by-Step Breakdown

- Material Selection: Choose biodegradable substrates such as cellulose or silk, and conductive materials like carbon nanotubes or biodegradable polymers.

- Sensor Design: Integrate organic thin-film transistors (OTFTs) or other components using flexible circuit printing.

- Data Transmission: Use low-power wireless protocols like Bluetooth Low Energy (BLE) to transmit sensor data in real time.

- Decomposition Timeline: After use, the sensor components begin to break down under natural conditions—typically within a few weeks to a few months.

- End-of-Life Processing: In compostable applications, used sensors can be disposed of directly in soil, where they decompose and enrich the environment.

Benefits for Industry and Environment

For Agriculture

- Reduces the need for manual field monitoring

- Enables precision farming

- Adds nutrients back to the soil

For Healthcare

- Reduces medical e-waste

- Enables short-term patient monitoring

- Offers low-cost diagnostics in rural areas

For the Environment

- Cuts down on microplastic pollution

- Prevents toxic heavy metal contamination

- Supports circular economy initiatives

Who’s Leading the Charge?

Several pioneering startups and institutions are at the forefront:

Epishine AB

A Swedish startup focused on printed organic solar cells. Their flexible power sources can be integrated with biodegradable sensors for energy-autonomous systems.

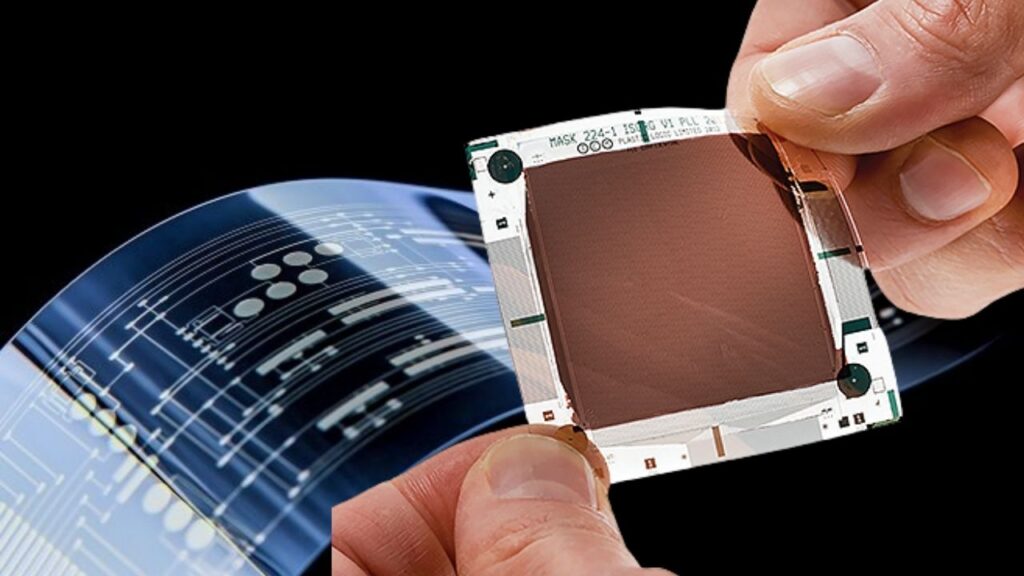

FlexEnable

A UK-based company developing organic thin-film transistors (OTFTs). Their technology supports flexible, sustainable electronics.

PyrAmes

Founded by Stanford University researchers, PyrAmes is building wearable health monitors using biodegradable tech to create smarter, greener healthcare.

Challenges and Limitations

While promising, biodegradable sensors face some hurdles:

- Shorter lifespan: Designed to degrade, they are not suitable for long-term applications.

- Limited data storage: Many rely on cloud connectivity since storing data onboard is complex.

- Performance trade-offs: Organic materials are still catching up to silicon in terms of speed and precision.

Yet, ongoing research and rising consumer demand for sustainable products continue to push innovation forward.

The Future of Biodegradable Tech

The global organic electronics market is projected to reach $160 billion by 2030 (Allied Market Research), with a growing share dedicated to green tech applications. Governments and private investors are pouring funds into R&D, with EU and US-based grants promoting sustainable electronic development.

Schools and universities are also adapting their curricula to focus on green engineering, preparing the next generation of scientists and entrepreneurs to carry this revolution forward.

Optical Modulators and Their Critical Role in High-Speed Internet

Bioelectronics: When Biology and Electronics Merge to Heal

Breakthroughs in Flexible Solar Panels: The Future of Renewable Energy

FAQs About Startup Uses Organic Electronics to Build Biodegradable Smart Sensors

What are biodegradable sensors made from?

They are made from natural or compostable materials such as cellulose, biodegradable polymers, and conductive inks.

How long do biodegradable sensors last?

Most last from several days to a few months, depending on the environment and materials used.

Can I compost these sensors at home?

Some are home-compostable, especially those designed for agricultural use. Always check the manufacturer’s disposal instructions.

Are biodegradable sensors safe for medical use?

Yes. Many meet health and safety standards for temporary monitoring, but they are typically not used for critical care.

How are they powered?

Some use small, flexible batteries, while others are powered by organic solar cells like those from Epishine.