Turning Heat into Power: Harnessing waste heat and converting it into usable electricity has long been a goal for scientists and engineers striving to improve energy efficiency and sustainability. With the rapid advancement of thermoelectric materials, this goal is closer than ever. These new materials have the potential to turn heat into power effectively, offering a groundbreaking way to reduce energy waste in industries, transportation, and even daily life.

In this article, we will explore how thermoelectric materials work, recent innovations that are driving this revolution, and practical examples of how this technology can be applied. Whether you’re a curious reader or an energy professional, this guide breaks down complex ideas into clear, actionable insights.

Table of Contents

What Are Thermoelectric Materials?

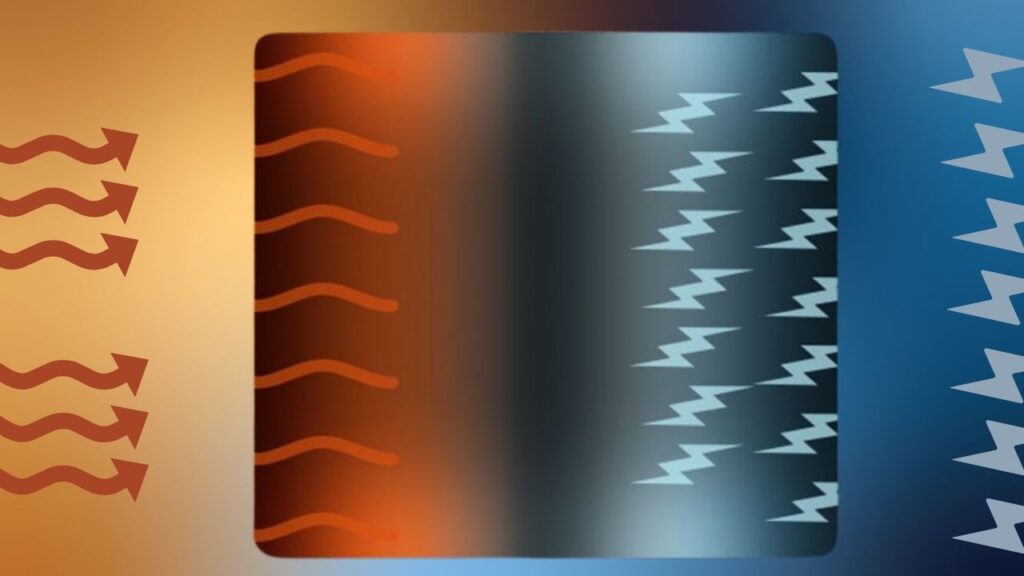

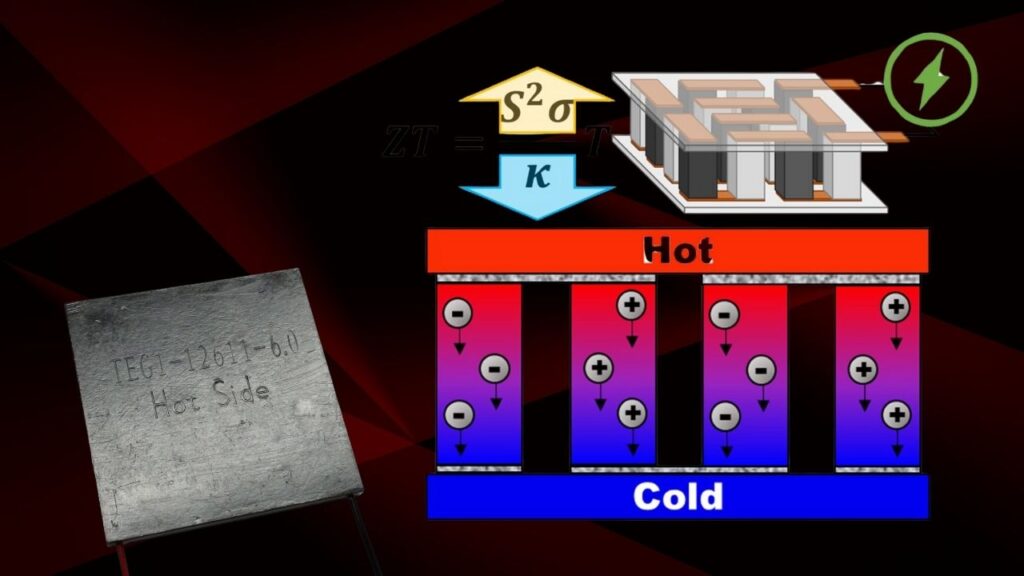

Thermoelectric materials are special substances that can convert temperature differences directly into electricity without any moving parts. This happens through the Seebeck effect, where a temperature difference between two ends of a material generates an electric voltage.

Imagine you have a hot surface on one side and a cold surface on the other. The thermoelectric material sandwiched between these surfaces will create an electric current that can power devices or charge batteries.

This process is incredibly useful because about 60% of the energy produced worldwide is lost as waste heat, especially in power plants, factories, and vehicles. Recovering even a fraction of that heat as electricity could lead to significant energy savings and reduced greenhouse gas emissions.

Historical Context: The Evolution of Thermoelectric Materials

The thermoelectric effect was discovered in the early 19th century, but initial materials were inefficient and costly, limiting practical applications. Over decades, advances in materials science, nanotechnology, and fabrication methods have steadily improved performance. Today’s breakthroughs represent a quantum leap from the bulky, low-efficiency devices of the past.

Turning Heat into Power

| Topic | Details |

|---|---|

| What are Thermoelectric Materials? | Materials that convert heat directly into electricity via the Seebeck effect. |

| Energy Loss from Waste Heat | Approximately 60% of global energy production is lost as waste heat |

| Efficiency Improvements | New materials can triple traditional thermoelectric efficiency |

| Applications | Industrial waste heat recovery, automotive exhaust energy, wearable devices, and space exploration. |

| Career Opportunities | Materials science, renewable energy engineering, nanotechnology, and sustainable manufacturing sectors. |

| Environmental Impact | Potential to reduce CO2 emissions by up to 10% globally if widely adopted |

| Official Resources | For more details visit U.S. Department of Energy. |

New thermoelectric materials are opening exciting possibilities for turning waste heat into usable power, boosting energy efficiency across many industries. From topological materials to printable graphene coatings, innovations are making these technologies more practical and affordable.

By understanding how these materials work, exploring their real-world applications, and recognizing challenges, we can appreciate their role in building a sustainable energy future. Whether in factories, cars, or wearable devices, turning heat into power is no longer science fiction but an achievable reality.

How Do Thermoelectric Materials Work?

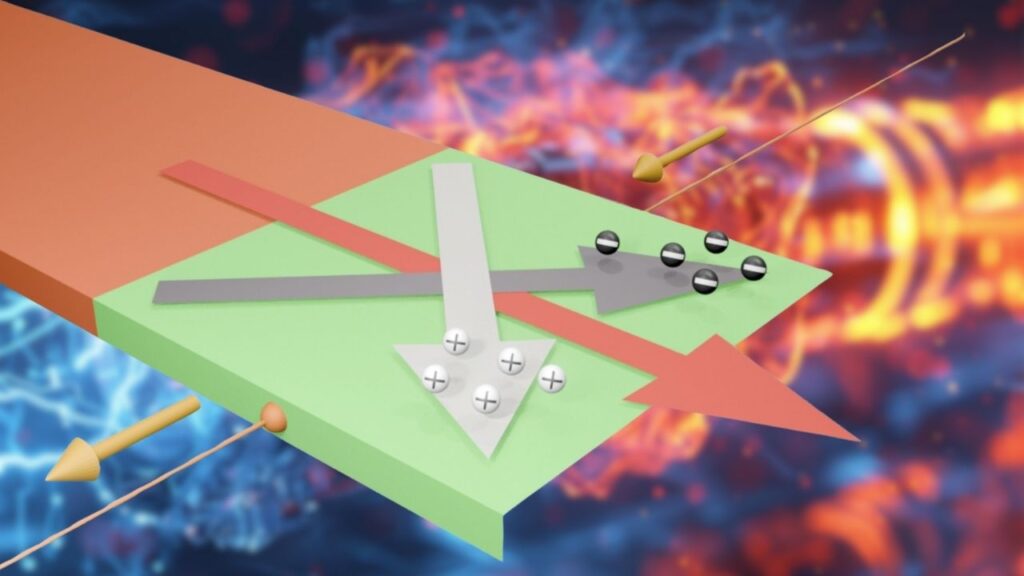

Thermoelectric materials rely on two related effects:

- Seebeck Effect: A temperature difference creates voltage.

- Peltier Effect: Applying voltage causes heat to move, used for cooling.

For turning waste heat into power, the Seebeck effect is the focus. When one side of a thermoelectric device is hot, and the other side is cooler, electrons in the material move, generating electricity.

The efficiency of this conversion is measured by a number called the figure of merit (ZT). Higher ZT values mean better performance. Traditional thermoelectric materials have ZT values around 1, but recent research has developed materials with ZT values exceeding 3, meaning they can be three times more efficient.

Recent Breakthroughs in Thermoelectric Materials

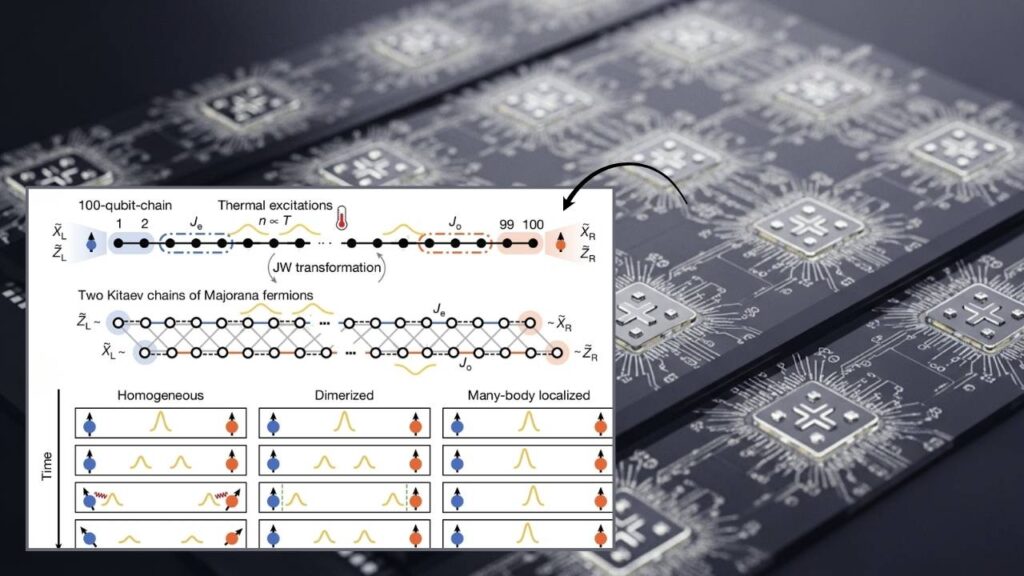

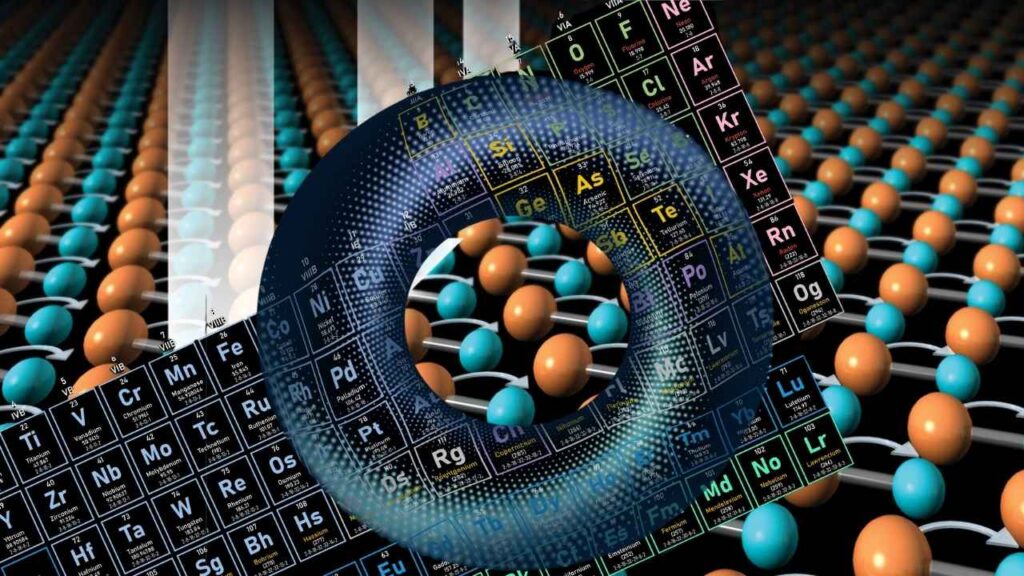

1. Topological Materials

Researchers at MIT discovered topological materials that possess unique electronic structures. These materials allow electrons to flow with less resistance, increasing thermoelectric efficiency dramatically. This could lead to devices that harvest more energy from smaller temperature differences, making them practical in many new settings.

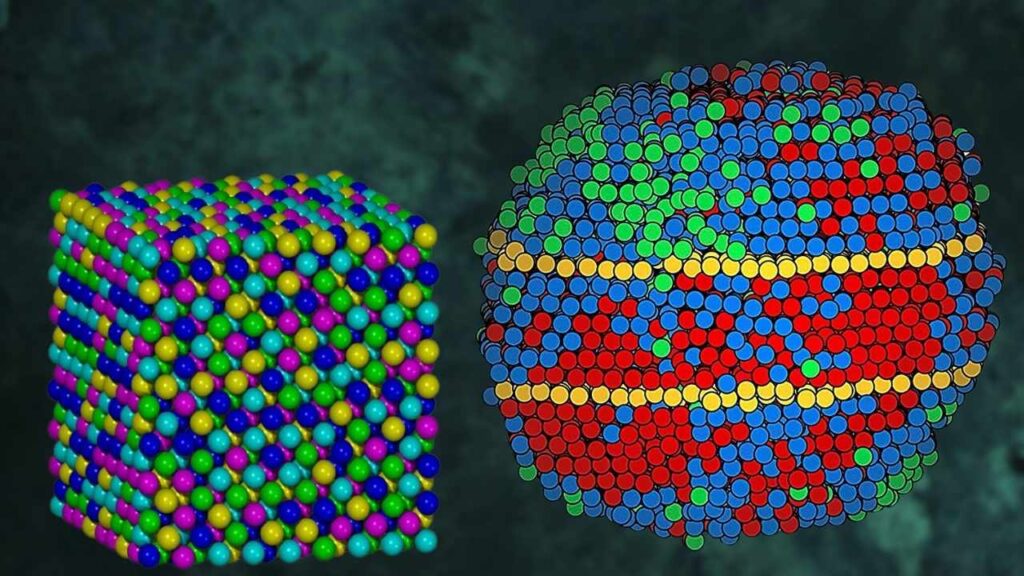

2. High-Entropy Alloys

A team at Penn State developed high-entropy alloys—complex materials made from several elements mixed together in nearly equal amounts. These alloys have highly disordered atomic structures that reduce heat flow but allow electrical current to pass, boosting efficiency.

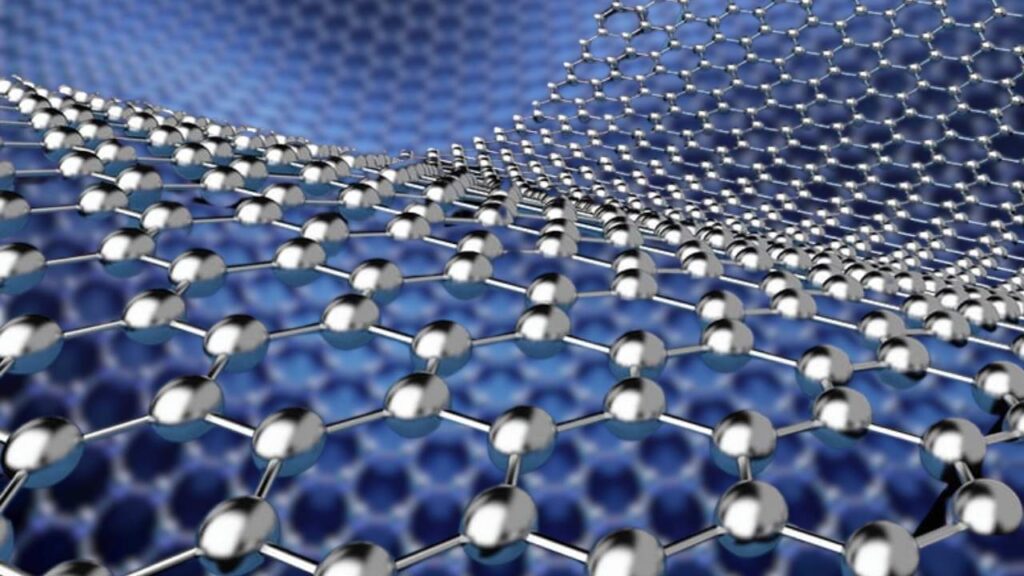

3. Printable Graphene Coatings

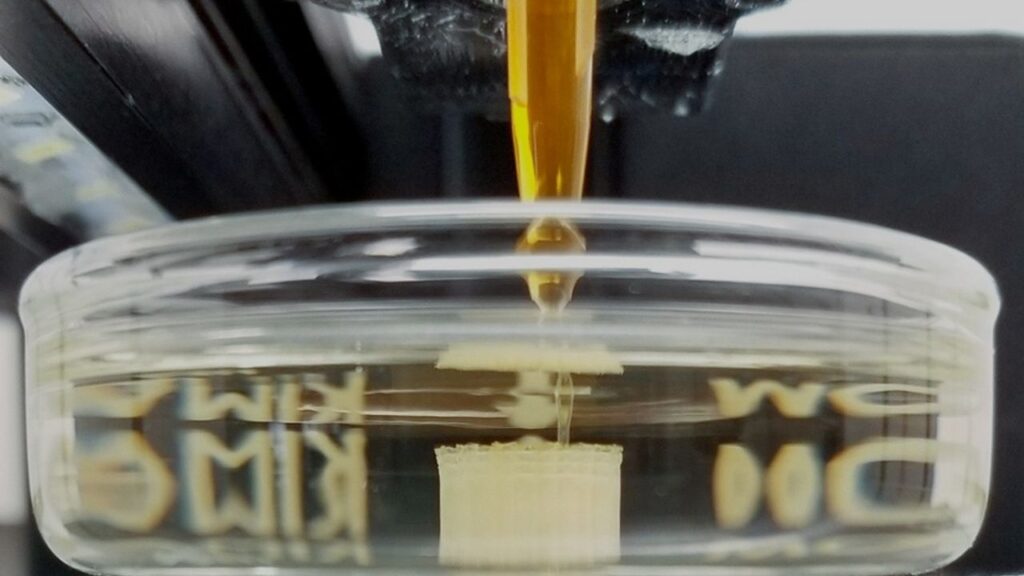

Scientists at the University of Sussex created a printable graphene-based coating that can be applied to surfaces. Graphene’s extraordinary electrical properties make it ideal for converting heat into electricity, and its flexibility enables integration into wearable tech or irregular surfaces.

4. Tungsten Disilicide Semimetals

Japanese researchers at Tokyo University of Science discovered tungsten disilicide, a semimetal that converts heat with low energy loss. This material shows promise for high-performance thermoelectric generators in harsh environments.

5. Machine Learning and 3D Printing

Using machine learning to design complex 3D architectures, researchers have optimized thermoelectric properties for room-temperature applications. This integration of AI accelerates material discovery and allows fabrication of customized thermoelectric devices.

Challenges and Limitations

Despite promising advances, thermoelectric technology faces challenges:

- Cost: Many high-performance materials use rare or expensive elements.

- Scalability: Manufacturing techniques must evolve to produce materials at scale affordably.

- Durability: Long-term stability under extreme temperature differences needs improvement.

- Efficiency Plateau: While ZT values are improving, efficiency gains slow as limits are approached.

Ongoing research aims to address these issues to make thermoelectric devices widely practical.

Environmental Impact: How Much Could We Save?

The Environmental Protection Agency estimates that by recycling waste heat with thermoelectric generators, global CO2 emissions could be reduced by up to 10%. This would significantly contribute to meeting climate goals like those outlined in the Paris Agreement.

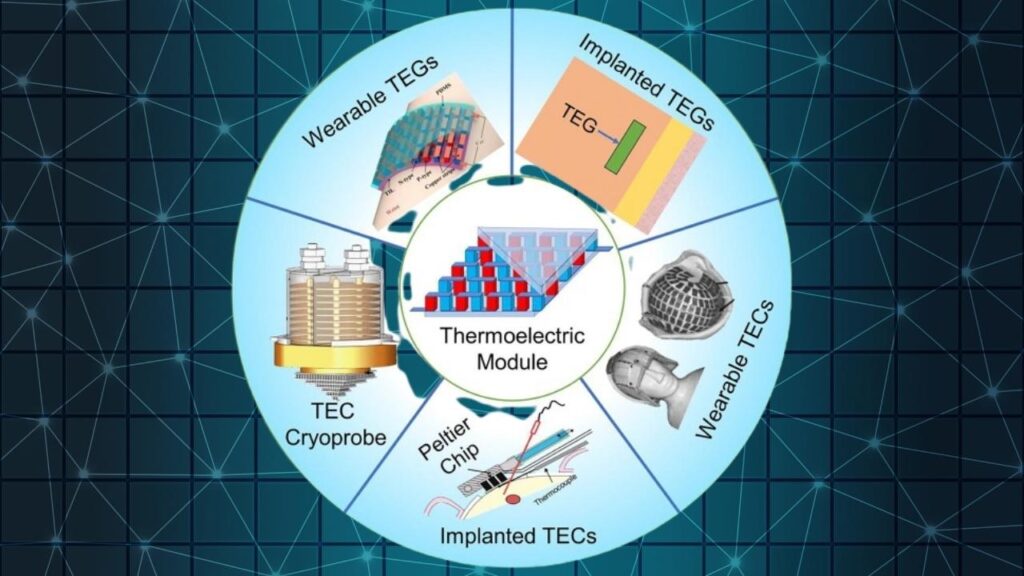

Practical Applications of Thermoelectric Technology

Industrial Waste Heat Recovery

Manufacturing facilities produce large amounts of heat that often escapes into the atmosphere. By installing thermoelectric generators on pipes or exhausts, factories can capture this energy and reduce operational costs.

Example: The steel industry generates up to 15-25% of its energy as waste heat, which could potentially be recycled to power auxiliary systems.

Automotive Industry

Vehicle engines produce heat that is typically wasted through exhaust gases. Thermoelectric generators attached to exhaust systems can convert this heat to electricity, reducing fuel consumption and emissions.

Example: Companies like BMW and Toyota are experimenting with thermoelectric generators to improve vehicle fuel efficiency.

Wearable Technology

Wearable devices powered by body heat are an emerging market. Flexible thermoelectric materials allow these devices to operate without batteries by converting the wearer’s body heat into electrical power.

Example: Smartwatches or medical sensors powered continuously by body heat improve convenience and sustainability.

Space Exploration

Space missions often use thermoelectric generators to power spacecraft where solar panels are not feasible. New materials could increase power output, extending mission duration and capabilities.

Example: The Mars rovers rely on radioisotope thermoelectric generators for continuous power.

Step-by-Step Guide: How To Implement Thermoelectric Generators

- Assess Heat Sources: Identify where waste heat is available in your facility or product.

- Choose Suitable Thermoelectric Materials: Select materials based on operating temperature and environment.

- Design Integration: Engineer thermoelectric modules that fit onto heat sources without disrupting operations.

- Install Power Management Systems: Include converters and storage for the generated electricity.

- Monitor and Maintain: Regularly check device efficiency and durability, replacing modules as needed.

- Scale Up: Expand successful pilots to larger-scale applications for maximum impact.

Thermoelectrics vs. Other Renewable Energy Technologies

Unlike solar or wind power, thermoelectric generators operate continuously, day and night, as long as there is a temperature difference. This makes them ideal for supplementing intermittent renewables and improving overall grid stability.

Career Opportunities and Industry Outlook

The growing importance of thermoelectric technology opens diverse careers in materials science, renewable energy, nanofabrication, AI-driven materials design, and sustainable manufacturing. Professionals with skills in these areas are in high demand to accelerate innovation.

Graphene Breakthrough Promises Faster, Smaller, More Efficient Electronics

Scientists Develop Self-Healing Materials for Electronics and Wearable Devices

The Rise of Electrochromic Glass: Smart Windows That Save Energy and Adapt to Light

FAQs About Turning Heat into Power

What is the Seebeck effect?

The Seebeck effect is the phenomenon where a temperature difference across a material creates an electric voltage.

How efficient are thermoelectric materials?

Current cutting-edge materials have efficiencies up to three times better than traditional ones, with ZT values above 3.

Can thermoelectric generators replace batteries?

In some cases, yes—especially for low-power devices like sensors or wearables that can harvest energy continuously from heat.

Are thermoelectric materials environmentally friendly?

Yes, they convert waste heat into clean electricity, reducing fossil fuel consumption and emissions.

Where can I learn more about thermoelectric materials?

Trusted sources include the U.S. Department of Energy, MIT News, and IEA.