Innovative Composite Material: Innovative composite material helps solar panels stay cooler and work more efficiently—a breakthrough that promises to reshape the solar energy landscape, especially in regions plagued by intense heat and sunlight. As solar power becomes an ever more critical component of the global energy transition, overcoming the challenge of heat-related efficiency losses is vital.

This article provides a comprehensive, clear, and authoritative guide to this exciting new technology, designed to be easily understood by readers of all backgrounds while offering valuable insights for professionals in renewable energy, materials science, and solar panel installation industries.

Table of Contents

Innovative Composite Material

| Feature | Description |

|---|---|

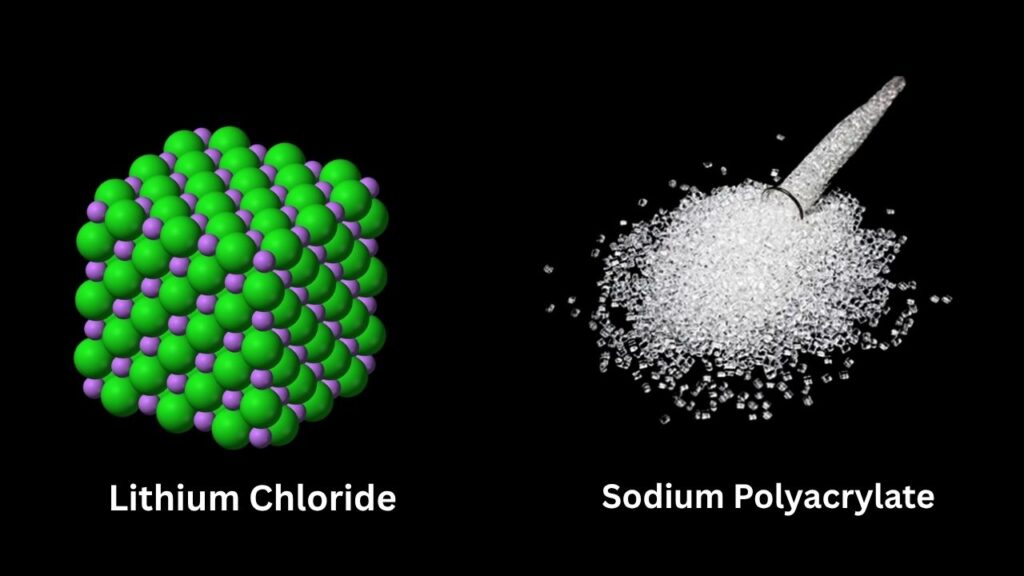

| Material Composition | Hygroscopic composite combining lithium chloride and sodium polyacrylate |

| Cooling Mechanism | Passive, moisture-based evaporation cooling without additional power |

| Temperature Reduction | Reduces solar panel temperature by up to 9.4°C (approx. 17°F) |

| Efficiency Gain | Improves solar panel power output by up to 12.9% under real-world conditions |

| Extended Durability | Increases panel lifespan by more than 200% by reducing thermal stress |

| Application | Suitable for new and existing panels, especially in hot, arid climates |

| Cost Efficiency | Low-cost materials, easy application, scalable for residential and utility use |

The innovative hygroscopic composite material offers a smart, cost-effective, and sustainable solution to one of solar energy’s biggest challenges: overheating. By leveraging the natural process of moisture absorption and evaporation, this technology can reduce solar panel temperatures by nearly 10°C, boosting output by up to 13%, and extending system life by over 200%.

For solar developers, installers, and policymakers looking to maximize clean energy production and durability—especially in hot and arid regions—this breakthrough provides a practical pathway forward. It exemplifies how simple, passive technologies can create outsized impacts in the pursuit of a greener future.

Understanding Why Solar Panels Overheat and Lose Efficiency

Solar panels convert sunlight into electricity using semiconductor materials, primarily silicon. While sunlight is essential for this process, heat is a double-edged sword: higher temperatures lead to decreased electrical output.

- Thermal Effects on Efficiency: The standard test condition temperature for silicon solar panels is 25°C (77°F). For every degree Celsius above this, panel efficiency typically drops by about 0.4% to 0.5%. This means at 60°C (140°F), panels can operate 14% to 17% less efficiently.

- Impact on Material Integrity: Thermal cycling (the repeated heating and cooling of panels) causes physical stress, leading to cracks and delamination in cells and solder joints. This accelerates degradation and shortens panel lifespan.

- Environmental Context: Regions like the Middle East, India, Australia, and the southwestern United States experience prolonged periods of intense sunlight and high ambient temperatures, sometimes exceeding 45°C (113°F). This environment severely challenges solar panel performance and durability.

Until recently, active cooling systems—fans, liquid cooling loops, or phase-change materials—were the main approaches to mitigating heat. These systems, however, increase complexity, energy use, and costs, limiting widespread adoption.

What is the Innovative Hygroscopic Composite Material?

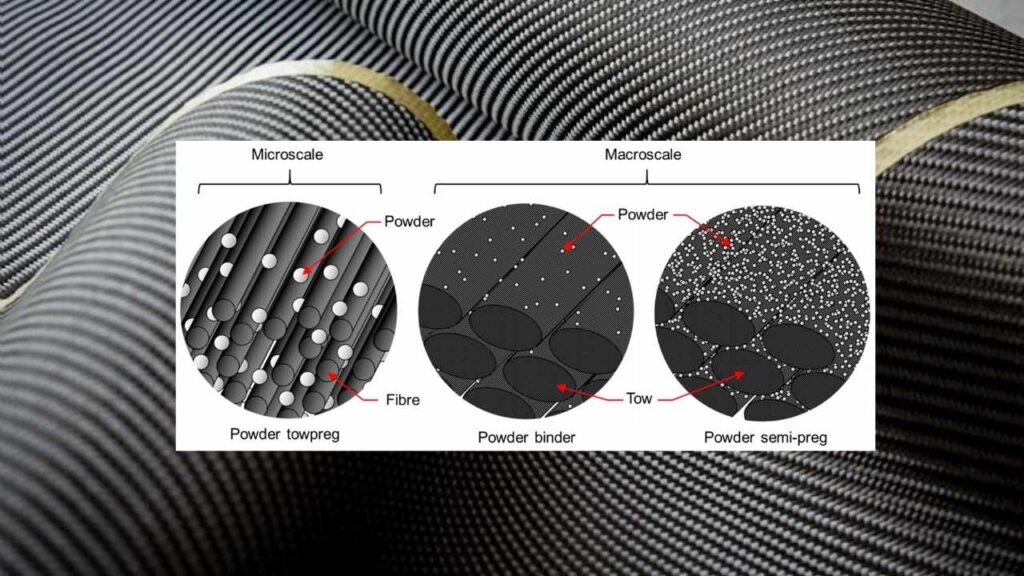

This novel material harnesses the property of hygroscopy—the ability of certain substances to absorb moisture from the air.

- Lithium Chloride (LiCl): A highly hygroscopic salt that can attract and hold significant amounts of moisture even in dry air.

- Sodium Polyacrylate: A polymer that absorbs water and swells into a gel-like substance, commonly used in diapers and agricultural products to retain moisture.

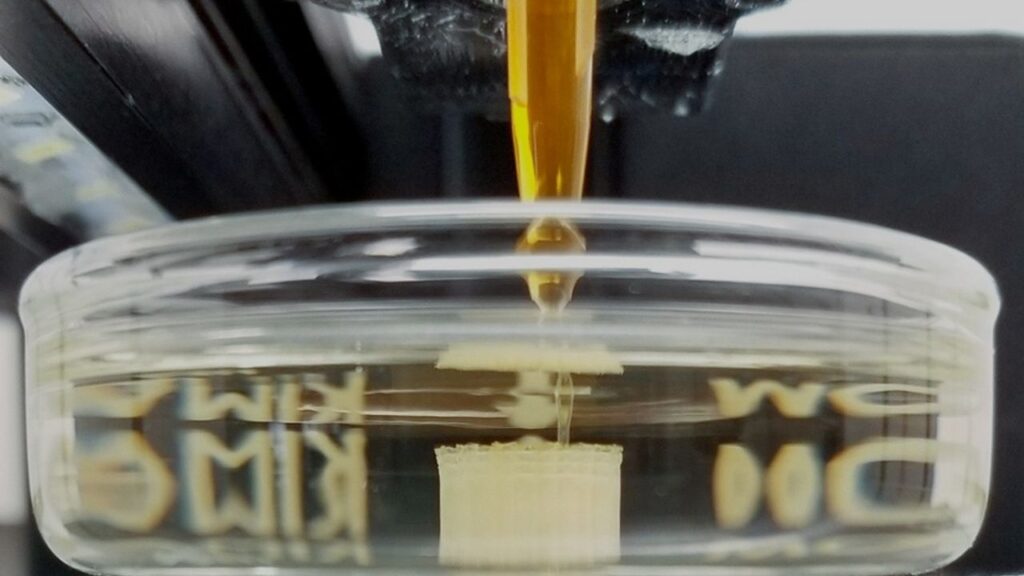

When combined, these substances form a composite layer that can be coated on the back or underside of solar panels.

How the Composite Works — The Cooling Cycle

- Nighttime Moisture Absorption

At night, when temperatures drop and relative humidity rises, the lithium chloride absorbs moisture from the air, which is retained within the sodium polyacrylate gel. - Daytime Evaporative Cooling

During the day, as the panel heats up, the water contained in the gel evaporates. This evaporation requires heat energy, which is drawn from the solar panel’s surface, effectively cooling it.

This cycle repeats daily, providing a self-sustaining passive cooling mechanism that requires no external energy or mechanical parts.

Quantifying the Benefits: Temperature Reduction and Power Gains

In field tests conducted under harsh desert conditions, the composite material has demonstrated:

- Temperature Reduction: Panels treated with this coating remained on average 9.4°C cooler than untreated panels under full sun.

- Efficiency Improvement: Cooler panels maintained higher voltage and current outputs, resulting in power generation improvements of up to 12.9%.

- Extended Panel Life: Reduced thermal stress slowed degradation processes, effectively tripling the operational lifespan of treated panels compared to untreated ones.

These figures reflect real-world conditions where dust, wind, and fluctuating humidity levels can affect performance. The passive nature of the cooling means no parasitic energy consumption or maintenance burdens.

Practical Application and Installation

How to Apply the Composite

- Surface Coating: The composite material is applied as a thin coating or spray on the rear surface of solar panels. This placement ensures it does not obstruct sunlight or reduce panel transparency.

- Compatibility: It is compatible with most silicon-based solar panels and can be applied to both new installations and existing arrays (retrofitting).

- Durability: The composite withstands outdoor exposure and retains functionality over long periods without frequent reapplication.

Installation Considerations

- Professional Application Recommended: To maximize performance and durability, professional installers can ensure even application and proper curing.

- Integration with Maintenance Schedules: It can be incorporated into routine panel cleaning and maintenance operations to minimize downtime.

- Cost Effectiveness: The materials used are inexpensive and widely available, making the solution accessible for residential users, commercial solar farms, and utility-scale projects.

Comparison with Other Cooling Technologies

| Cooling Method | Energy Use | Complexity | Cooling Effectiveness | Maintenance | Cost |

|---|---|---|---|---|---|

| Hygroscopic Composite | None | Low | High (up to 9.4°C) | Low | Low |

| Active Fan Cooling | Medium | Medium | Medium | Medium | Medium |

| Liquid Cooling | High | High | High | High | High |

| Phase-Change Materials | None | Medium | Moderate | Medium | Medium |

The passive composite solution excels because it requires no external power, avoids mechanical parts that fail, and provides significant cooling benefits with minimal maintenance.

Environmental and Economic Impact

Reducing Carbon Footprint

By improving panel efficiency and lifespan, fewer panels are needed to produce the same amount of energy, reducing raw material consumption and associated emissions.

Increasing Solar Viability in Hot Climates

Heat-related performance degradation has historically limited solar adoption in some regions. This technology can unlock higher returns on investment, accelerating the adoption of solar power where it is most needed.

Lowering Operation and Maintenance Costs

By reducing thermal damage, the composite lowers repair and replacement frequency, translating into substantial cost savings over the system’s lifetime.

AI-Driven Models Accelerate Molecular and Materials Discovery in Biomedical Research

Superconducting Diode Bridge Efficiently Converts AC to DC for Quantum Circuits

China Develops High-Resolution Laser Capable of Reading Tiny Text from Over a Kilometer Away

FAQs About Innovative Composite Material

Is the material safe for the environment and humans?

Yes, the materials are chemically stable, non-toxic in small quantities, and do not release harmful substances under normal conditions.

Can this technology be used with different types of solar panels?

The composite is primarily designed for silicon-based photovoltaic panels but could potentially be adapted for other panel technologies with similar thermal characteristics.

Does the effectiveness depend on local climate?

While performance is optimal in areas with significant diurnal humidity variation, the composite has proven effective even in arid environments by absorbing minimal but sufficient moisture at night.

How often does the coating need to be reapplied?

Initial studies suggest the coating remains effective for several years under typical weather conditions, but exact longevity depends on local environmental factors.