New 3D Textile Material: The new 3D textile material designed to improve mobility and comfort in wearable tech is rapidly transforming the landscape of smart clothing and wearable devices. By integrating advanced materials science and textile engineering, these fabrics offer unprecedented flexibility, adaptability, and functionality. They enable wearables that don’t just monitor or assist but truly interact with the human body in a seamless, comfortable way.

From healthcare to sports, from fashion to rehabilitation, this innovation holds the potential to redefine wearable technology’s role in our everyday lives.

Table of Contents

New 3D Textile Material

| Topic | Details |

|---|---|

| Technology Name | ExoFabric, Cosyflex, Conductive 3D Textiles |

| Purpose | Improve mobility, comfort, and functionality of wearable tech |

| Core Innovations | Thermoplastic re-moldable fabrics, 3D printed electronics, stretchable conductive networks |

| Applications | Healthcare, rehabilitation, sports, fashion, thermal regulation |

| Performance Data | Stretchable fabrics maintain electrical conductivity after thousands of cycles |

| Market Outlook | Expected commercialization growth in the next 3–5 years |

New 3D textile materials designed to improve mobility and comfort in wearable tech are at the forefront of a wearable revolution. Combining cutting-edge materials science with textile engineering, they offer garments that adapt, support, and monitor the body like never before.

This evolution promises to impact healthcare, sports, fashion, and beyond—making wearable technology not just a tool, but a natural extension of the human body. As research continues, expect to see more comfortable, durable, and intelligent wearable textiles that enhance daily life and well-being.

Understanding 3D Textile Materials in Wearable Technology

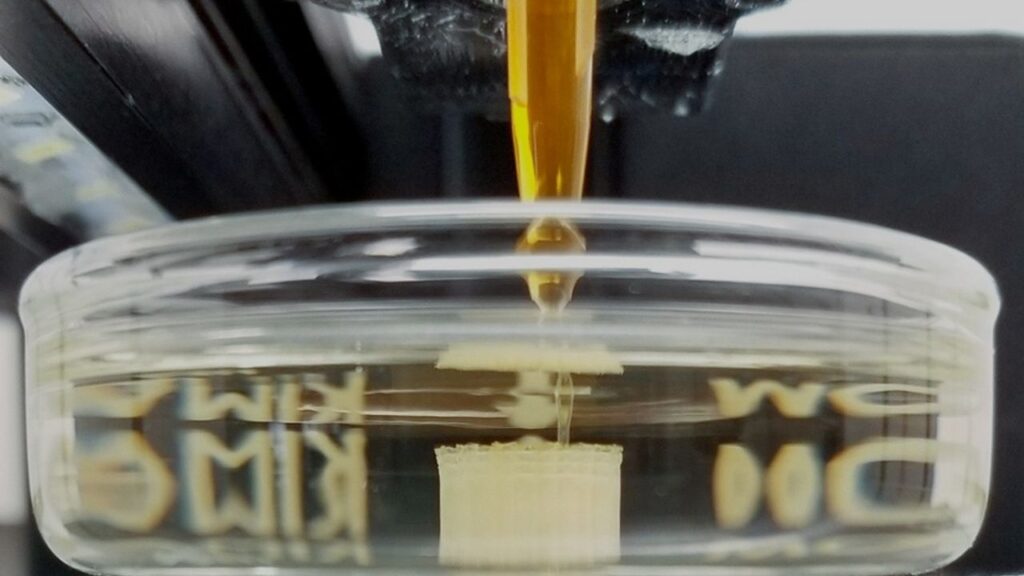

Traditionally, textiles are flat, two-dimensional materials. But 3D textile materials break this mold by incorporating depth, structure, and smart functionality directly into the fabric. They can conform to the human body’s complex shapes and movements, offering support and interaction without sacrificing comfort.

These textiles are created using innovative techniques like 3D weaving, knitting, or additive manufacturing (3D printing) combined with advanced materials such as thermoplastics, conductive polymers, and nano-engineered fibers.

Why does this matter? Because wearable tech embedded in traditional textiles often struggles with issues like stiffness, limited flexibility, and discomfort. 3D textiles address these challenges head-on by combining form and function at the material level.

Core Technologies Behind 3D Textile Innovation

1. Thermoplastic Re-moldable Fabrics (ExoFabric)

One leading technology in this space is the development of thermoplastic-based fabrics that can be reshaped with heat. Known as ExoFabric in research circles, this material can transition from soft and flexible to rigid and supportive as needed. When heated, it becomes pliable and can be molded to the wearer’s body, then hardens upon cooling—offering custom-fit support.

- Practical example: Athletes recovering from joint injuries can benefit from compression sleeves made of ExoFabric that provide both mobility and protection.

- Benefit: Reusable and customizable, reducing waste and improving long-term comfort.

2. 3D Printed Electronic Textiles (Cosyflex)

The Cosyflex platform uses 3D printing to embed electronic circuits directly onto or within textile fibers. Unlike traditional methods that sew or attach bulky devices, this technique integrates sensors, actuators, and interconnects with minimal thickness and maximum stretchability.

- Application: Shirts that monitor heart rate, respiration, and posture without bulky monitors.

- Advantage: Maintains fabric softness and stretch, crucial for daily wear.

3. Stretchable Conductive Networks

Stretchable fabrics infused with conductive materials like silver nanowires, carbon nanotubes, or MXenes have demonstrated remarkable durability and performance. These networks maintain electrical conductivity even after thousands of cycles of stretching, bending, and washing.

- Performance note: Studies show retention of over 90% conductivity after extensive use, essential for reliable biometric sensing.

- Use case: Continuous monitoring of muscle strain or skin temperature during physical therapy.

Why Mobility and Comfort Are Critical for Wearable Tech

While wearable technology offers incredible potential, user compliance is often hindered by discomfort or limited functionality. Devices that restrict movement or cause irritation are unlikely to be worn consistently, reducing their effectiveness.

3D textile materials provide solutions to these common problems by:

- Conforming to diverse body shapes and sizes, offering personalized comfort.

- Eliminating pressure points that cause discomfort or skin breakdown.

- Supporting joints and muscles dynamically, assisting natural movement rather than restricting it.

Example: Rehabilitation garments that adapt their stiffness depending on muscle fatigue levels can enhance recovery by providing support only when needed, reducing muscle strain and improving mobility.

Real-World Applications Across Industries

Healthcare and Rehabilitation

Wearable devices made with 3D textiles are revolutionizing patient care by providing continuous, non-invasive monitoring and support.

- Smart bandages with embedded sensors can track wound healing progress and alert patients or caregivers to infections.

- Compression garments embedded with strain sensors help monitor joint mobility in stroke or arthritis patients.

- Thermal regulation wearables adjust temperature based on patient needs, improving comfort and recovery outcomes.

Sports and Fitness

Athletes benefit from smart garments that monitor physiological parameters without restricting performance.

- Real-time biometric data such as heart rate variability, muscle oxygenation, and hydration levels help optimize training and prevent injury.

- Adaptive compression clothing can change pressure dynamically to improve blood flow and reduce fatigue.

Fashion and Sustainability

Beyond health and sports, 3D textile technology is driving innovation in fashion with:

- Customization: Clothes tailored to individual body shapes without waste.

- Dynamic aesthetics: Fabrics that change color or texture based on environmental factors or wearer mood.

- Sustainable materials: Durable fibers that reduce landfill waste and enable recycling.

How Are These Smart 3D Textiles Made? A Step-by-Step Guide

- Material Selection: Experts choose suitable polymers, thermoplastics, or conductive fibers based on desired properties like stretchability, conductivity, and durability.

- Textile Fabrication: Advanced weaving, knitting, or embroidery techniques integrate functional fibers and conductive yarns directly into the fabric’s 3D structure.

- Electronic Integration: Using 3D printing or other additive manufacturing, electronic circuits, sensors, and actuators are embedded within or on the textile surface.

- Quality Testing: Textiles undergo rigorous mechanical, electrical, and washability tests to ensure performance under real-world conditions.

- Final Product Development: The textiles are fashioned into wearable products—such as shirts, sleeves, or socks—designed for specific applications.

Current Challenges and Future Perspectives

While 3D textile materials have made impressive progress, several challenges remain:

- Cost and Scalability: Manufacturing these advanced textiles is still expensive and complex, limiting widespread adoption.

- Durability: Repeated washing, stretching, and daily wear degrade some materials over time, necessitating further innovation.

- Data Security: As wearables collect sensitive health data, robust privacy and security protocols are essential.

Looking ahead, integration with artificial intelligence could enable garments to automatically adjust stiffness, temperature, or compression based on real-time data, providing personalized care and comfort like never before.

New Materials Support Progress Toward More Reliable Quantum Computers

FAQs About New 3D Textile Material

What materials are used in 3D textile wearables?

They typically use thermoplastics, stretchable polymers, conductive fibers (silver nanowires, carbon nanotubes), and flexible electronics.

Can these smart textiles be washed like regular clothes?

Most require gentle or hand washing, with ongoing research focused on improving wash durability without damaging electronics.

Are 3D textile wearables safe for children and elderly?

Yes, they can be designed for sensitive skin and adapted for pediatric or geriatric care, especially for monitoring chronic conditions or mobility support.

When will these textiles be widely available?

Commercial availability is expanding, with consumer-ready products expected to grow significantly over the next 3 to 5 years as costs decrease.