MIT Engineers Develop New 3D Printing Method: In recent years, 3D printing—also known as additive manufacturing—has transformed from a niche prototyping tool into a powerful technology used across industries like aerospace, healthcare, and automotive. However, despite its many advantages, a significant challenge has persisted: the need for support structures during printing that generate large amounts of waste and require manual removal.

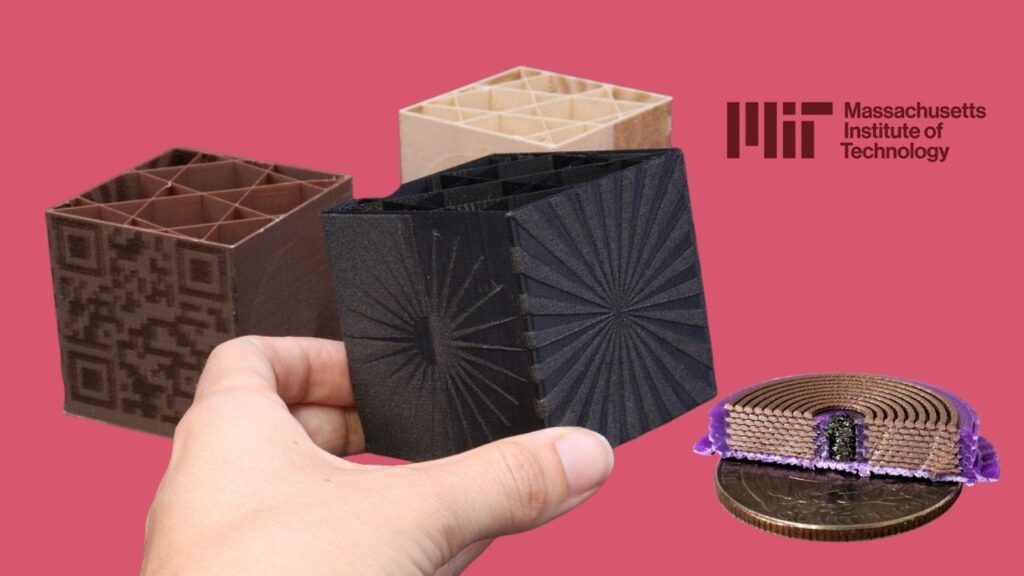

Now, engineers at MIT have developed a revolutionary 3D printing method that dramatically reduces waste while enabling the production of complex, interlocking designs in a single print. This method employs a novel dual-phase resin and an innovative curing process that allows supports to dissolve safely after printing and be recycled back into the system. The result is a cleaner, more sustainable printing process with new possibilities for design and manufacturing.

MIT’s breakthrough in 3D printing technology addresses two major challenges: reducing waste from support materials and enabling the creation of complex, interlocking designs in a single print. Through a novel dual-phase resin that reacts differently to UV and visible light, this method allows for dissolvable supports that can be recycled, offering significant environmental and economic benefits.

As this technology moves toward commercialization, it holds promise to revolutionize manufacturing in aerospace, healthcare, and beyond. For professionals and enthusiasts alike, it marks a pivotal step toward truly sustainable, flexible, and intelligent 3D printing.

Table of Contents

Understanding the Challenge: Waste and Complexity in 3D Printing

What Are Support Structures and Why Are They Necessary?

3D printing builds objects layer by layer. When printing complex shapes, overhangs and floating parts require temporary support to prevent collapse during fabrication. These supports often use the same material as the main object but are discarded after printing.

According to industry reports from Wohlers Associates, support materials can account for 30-70% of total print volume in complex parts, contributing significantly to material waste and post-processing labor costs.

This is not only inefficient but also environmentally damaging. Most support materials are non-recyclable, ending up in landfills or requiring energy-intensive disposal.

What MIT’s New Method Brings to the Table

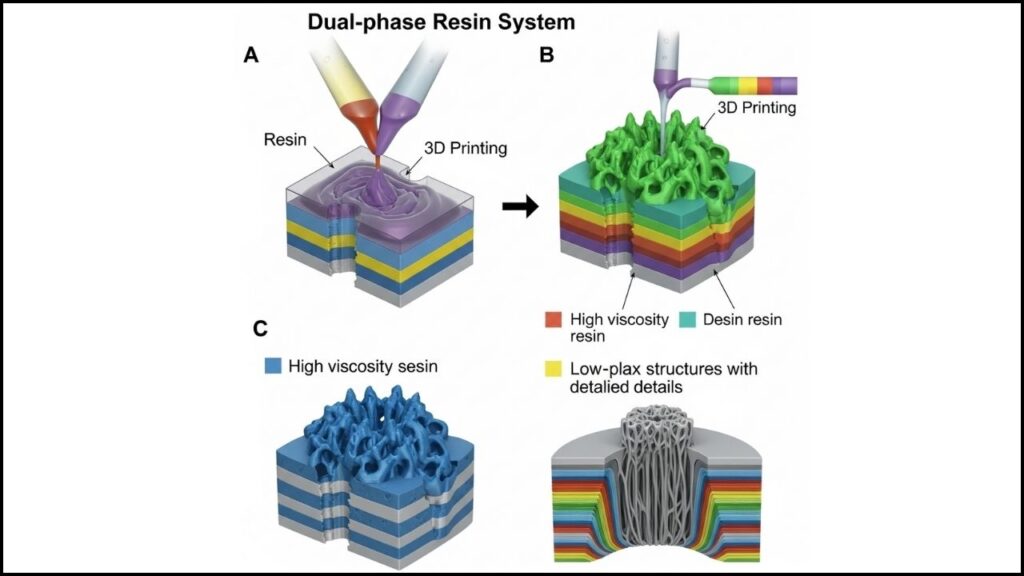

MIT’s innovation hinges on a dual-phase resin system—a polymer mixture that reacts differently depending on the type of light it is exposed to during printing.

- Ultraviolet (UV) light cures the resin into a strong, durable material for the main parts.

- Visible light exposure converts the resin into a dissolvable support material, designed to be removed easily after printing.

This dual curing allows the printer to “switch” materials on the fly during a single print, creating permanent structures and temporary supports without changing materials or print heads.

A Closer Look at the Resin Chemistry

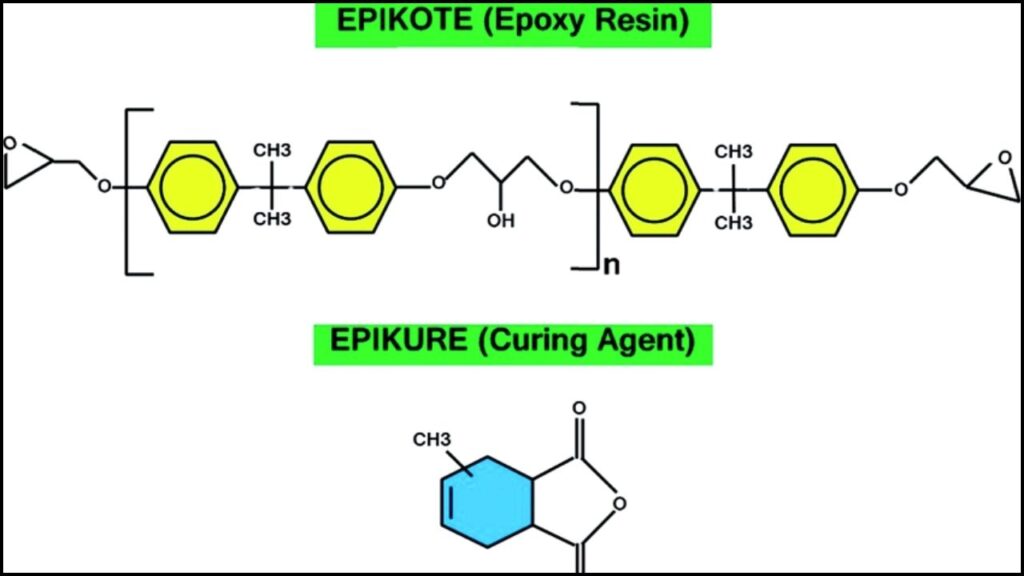

The resin comprises three main components:

- Base Monomers – form the main polymer matrix when cured by UV light.

- Photo-Initiators – molecules that respond to specific wavelengths to trigger polymerization.

- Bridging Monomers – introduced to improve cross-linking during UV curing, ensuring mechanical strength.

Early experiments showed UV-cured resin lacked toughness, a problem solved by adding a bridging monomer that creates stronger bonds between polymer chains under UV exposure. This improvement ensures the printed parts are structurally sound while keeping the supports easily dissolvable.

Step-by-Step Guide: How This 3D Printing Process Works

Step 1: Design Your Model

Design your 3D model using CAD software, specifying which parts require support. The software integrates with the printer to assign UV or visible light exposure to each layer or region.

Step 2: Print With Dual-Phase Resin

The printer uses both UV and visible light sources simultaneously or sequentially:

- UV light solidifies the main structure.

- Visible light cures the support regions into a dissolvable material.

This process allows complex shapes, interlocking parts, and moving mechanisms to be printed in one continuous session.

Step 3: Post-Processing – Dissolving Supports

Once printing is complete, the object is immersed in a solvent bath—commonly baby oil or similar gentle oil-based solvents. This bath:

- Dissolves the support material without damaging the main structure.

- Allows supports to be removed cleanly, reducing manual labor and surface finishing.

Step 4: Resin Recycling

The dissolved support material is filtered and reclaimed. The resin is then purified and reintroduced into the printing system, reducing the need for fresh material and lowering environmental impact.

Real-World Applications: Practical Examples

1. Functional Mechanical Parts

MIT researchers printed gear trains and articulated joints as a single assembly. Normally, these parts require printing each component separately, followed by manual assembly. Now, fully functional mechanisms can be printed ready-to-use, cutting manufacturing time and costs.

2. Dental and Biomedical Implants

Custom dental implants demand precise geometries and biocompatibility. The dissolvable supports allow printing of complex implant geometries with fine internal channels for tissue integration, impossible with traditional methods.

3. Lightweight Aerospace Structures

Lattice frameworks and internal channels can be printed with fewer material constraints. The support removal system enables designs with optimized strength-to-weight ratios, crucial for aerospace applications.

The Environmental and Economic Impact

Waste Reduction

By enabling support material recycling, MIT’s method could cut waste by up to 50-70% for complex prints. Given that the global 3D printing market reached $21 billion in 2024, this translates into a considerable reduction in plastic waste annually.

Cost Efficiency

Material costs can be a major factor in 3D printing. With less support material wasted and the ability to recycle dissolved resin, manufacturers could see cost savings of 15-30%, according to preliminary industry analyses.

Energy Savings

Reducing post-processing steps like manual support removal lowers labor costs and energy consumption—further supporting sustainable manufacturing goals.

How Does This Compare to Existing Technologies?

Conventional Support Removal

Most printers rely on breakaway or water-soluble supports. Breakaway supports require manual removal, risking damage and increasing labor time. Water-soluble supports use chemicals like sodium hydroxide but can damage delicate parts.

MIT’s oil-soluble supports are gentler, recyclable, and easier to handle.

Multi-Material Printing

Other systems use multiple print heads for different materials, increasing printer complexity and cost. MIT’s method uses a single resin with dual light curing, simplifying hardware requirements.

Expert Opinions and Industry Outlook

Dr. Robert Macfarlane, one of the lead MIT researchers, noted, “Our goal was to rethink how materials behave during printing, enabling greater design freedom while prioritizing sustainability.”

Industry leaders like Stratasys and Formlabs have expressed interest in integrating dual-phase resins into their platforms, acknowledging the potential for improved efficiency and sustainability.

New 3D Textile Material Designed to Improve Mobility and Comfort in Wearable Tech

FAQs About MIT Engineers Develop New 3D Printing Method

How soon will this technology be available commercially?

The technology is currently in advanced research stages. Industry adoption may take 2-5 years, depending on scale-up and integration with existing printers.

Is this method compatible with all 3D printers?

It requires printers equipped with both UV and visible light sources capable of controlled wavelength exposure, which some commercial SLA printers can be retrofitted to support.

Are there any health or safety concerns with the resin or solvents used?

The resin is chemically complex but designed to be stable and safe when cured. The baby oil solvent is non-toxic and widely available, posing minimal risk compared to industrial chemicals.

Can the recycled resin be reused indefinitely?

While recycling reduces waste, resin properties may degrade after multiple cycles. Ongoing research focuses on maximizing recyclability without sacrificing print quality.