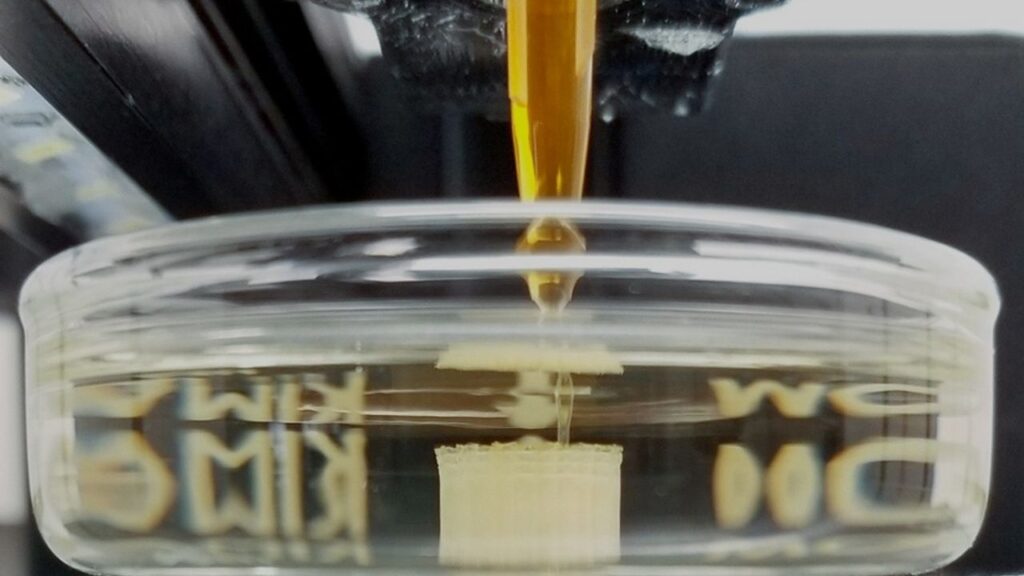

Japan Develops Plastic That Dissolves in Seawater: Japan has achieved a significant milestone in environmental science by developing a new type of plastic that dissolves in seawater within hours. This innovative plastic material, created by researchers at the RIKEN Center for Emergent Matter Science and the University of Tokyo, offers a promising solution to the escalating problem of ocean plastic pollution—a crisis threatening marine ecosystems worldwide.

Unlike traditional plastics, which can persist in oceans for centuries, fragmenting into harmful microplastics, this new polymer dissolves quickly in seawater without leaving toxic residues or microplastic debris. It combines strength and durability comparable to conventional plastics with environmental safety and biodegradability, potentially transforming industries that rely heavily on single-use plastics, such as packaging and fishing.

Japan’s innovative seawater-dissolving plastic represents a transformative advance in tackling one of the planet’s most pressing environmental problems. By combining durability with rapid, non-toxic degradation in marine environments, this new material offers a practical path forward to reduce ocean plastic pollution.

As industries and governments increasingly commit to sustainability, such innovations will be critical to preserving marine biodiversity and safeguarding human health for future generations.

Table of Contents

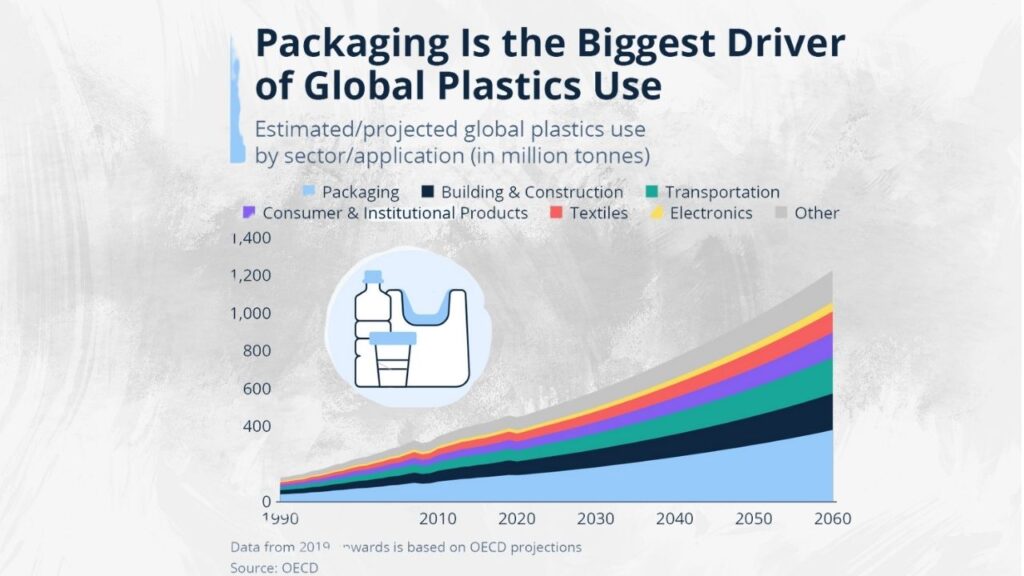

Why This Innovation Matters: The Plastic Pollution Crisis

According to the United Nations Environment Programme (UNEP), approximately 11 million metric tons of plastic waste enter the oceans annually. If current trends continue, this volume could triple by 2040, severely impacting marine biodiversity, human health, and global economies (UNEP Beat Plastic Pollution).

Traditional plastics degrade very slowly in marine environments. Over decades or centuries, they break down into smaller particles known as microplastics. These microplastics:

- Are ingested by a wide range of marine animals, from plankton to whales

- Enter the human food chain through seafood consumption

- Carry toxic chemicals and pathogens

The environmental and economic damages caused by marine plastic pollution are immense. The World Bank estimates that plastic pollution costs the global economy over $13 billion annually, affecting fisheries, tourism, and coastal communities (World Bank Report).

What Makes Japan’s Plastic Different?

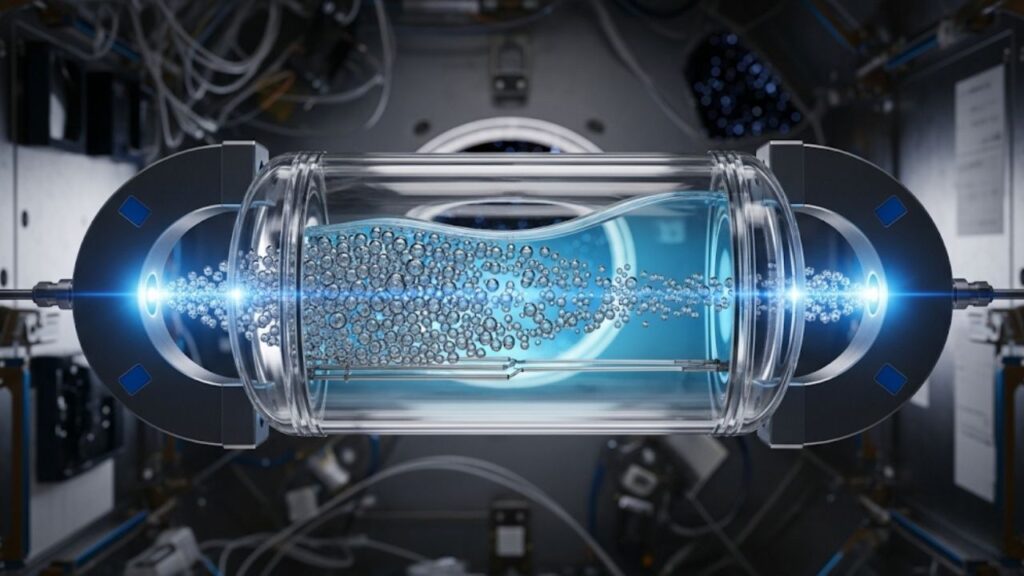

Japan’s new plastic, referred to as a marine-dissolvable polymer, was developed through extensive research to address the shortcomings of conventional plastics and even many biodegradable alternatives.

Key Features

- Rapid Dissolution: It dissolves completely within about 1 hour when placed in agitated seawater (moving water simulates ocean currents).

- Saltwater Reaction: The plastic specifically reacts to sodium ions present in seawater, which trigger its decomposition.

- No Harmful Residues: The breakdown process produces no toxic chemicals or microplastics.

- Biodegradable: Residues are biodegradable by natural marine bacteria.

- Soil Degradation: The plastic also decomposes in soil in roughly 200 hours, depending on conditions.

- Physical Strength: It maintains physical durability comparable to conventional plastics when dry and unused.

This combination of durability and rapid degradation in marine environments is unprecedented.

How Does It Work? The Science Behind the Polymer

The plastic consists of a proprietary polymeric compound designed to be stable under normal conditions—such as in packaging or product use—but highly reactive when exposed to seawater.

- The polymer chains are sensitive to the ionic composition of seawater.

- When submerged, salt ions initiate a chemical reaction that breaks down polymer bonds.

- The material fragments rapidly and dissolves into water-soluble compounds.

- These compounds are then metabolized by marine microorganisms, completing the biodegradation cycle.

Dr. Takuzo Aida, lead researcher at the University of Tokyo, describes it as “a time-release capsule that retains product integrity until it reaches the ocean environment, where it safely and quickly disappears.”

Environmental and Economic Implications

Environmental Benefits

- Elimination of Microplastics: Because the plastic dissolves chemically rather than physically fragmenting, it does not create microplastics, a major environmental hazard.

- Non-Toxicity: It avoids toxic additives and plasticizers common in conventional plastics.

- Reduction in Carbon Footprint: Unlike many biodegradable plastics that require industrial composting, this material decomposes naturally in seawater without releasing greenhouse gases.

Economic Benefits

- The global cost of plastic pollution exceeds $13 billion annually, impacting fisheries, tourism, and clean-up efforts.

- Transitioning to marine-dissolvable plastics could reduce waste management costs and improve compliance with increasingly strict environmental regulations worldwide.

- Businesses adopting sustainable materials may benefit from enhanced brand reputation and access to growing environmentally conscious markets.

Potential Applications and Industry Impact

Packaging Industry

The packaging sector is the largest consumer of single-use plastics. Japan’s plastic offers a compelling alternative for:

- Food wrapping

- Shopping bags

- Disposable containers

Companies are exploring ways to integrate the polymer while maintaining product shelf life and safety.

Fishing and Marine Industries

Discarded fishing gear and nets contribute significantly to “ghost fishing” and marine pollution. This plastic could:

- Replace traditional nets and lines that persist for decades

- Reduce entanglement and ingestion hazards for marine species

Consumer Goods

The plastic’s durability and safety profile make it suitable for various consumer products where plastic waste commonly ends up in aquatic environments.

Regulatory and Market Landscape

Global Regulations Driving Innovation

- The UN Plastic Treaty, currently in negotiation, aims to establish global rules to reduce plastic pollution.

- Countries like Canada, France, and India have already implemented bans on specific single-use plastics.

- Japan’s new plastic aligns well with regulatory trends emphasizing marine biodegradability and reduced plastic leakage.

Market Readiness and Challenges

- While promising, production costs remain higher than conventional plastics.

- Industrial scaling is underway, with pilot production expected in the next 1–2 years.

- Further research is focused on optimizing durability, cost, and application range.

Practical Guidance: How Consumers and Businesses Can Support Marine-Safe Plastics

For Consumers

- Choose products packaged in biodegradable or marine-safe materials.

- Avoid single-use plastics where possible.

- Look for eco-labels such as “marine degradable”, “compostable”, or “plant-based”.

For Businesses

- Evaluate supply chains for sustainable plastic alternatives.

- Collaborate with material scientists and suppliers to pilot new plastics.

- Educate customers on the environmental benefits of eco-friendly packaging.

The Future of Displays: How MicroLEDs Are Set to Outshine OLED Technology

Light-Powered Computing: The Race to Build the First All-Optical Processor

Turning Heat into Power: New Thermoelectric Materials Could Revolutionize Waste Energy Use

FAQs About Japan Develops Plastic That Dissolves in Seawater

1. When will this plastic be commercially available?

Commercial production is anticipated within 1–2 years after ongoing pilot and industrial scale-up phases.

2. Is the plastic stable in fresh water or rain?

Yes. The polymer specifically reacts to seawater’s salt content and remains stable in fresh water or rain, ensuring product safety during use.

3. Can this plastic fully replace all traditional plastics?

Not yet. Its ideal use is in products likely to end up in marine environments. Research continues to broaden its application.

4. What about the cost compared to conventional plastics?

Currently more expensive, but mass production and regulatory incentives are expected to reduce costs significantly.

5. Is this plastic harmful to marine life?

No. It decomposes into non-toxic compounds and does not form microplastics, making it safe for aquatic ecosystems.