Researchers Develop Metallic Materials Using Data-Driven Frameworks and Explainable AI: In a remarkable leap forward for materials science, researchers at Virginia Tech and Johns Hopkins University have pioneered a new way to create metallic materials using data-driven frameworks and explainable artificial intelligence (AI). This innovative approach is not just making metals stronger and more versatile—it’s transforming how we discover, understand, and use advanced alloys in fields as diverse as medicine, aerospace, and renewable energy.

In this article, you’ll learn how these new methods work, why they matter, and what they mean for the future of technology and engineering. Whether you’re a student, a professional, or simply curious about science, you’ll find clear explanations, authoritative data, and actionable insights throughout.

Researchers Develop Metallic Materials Using Data-Driven Frameworks and Explainable AI

| Feature/Stat | Details |

|---|---|

| Project Leaders | Virginia Tech & Johns Hopkins University |

| Technology Used | Data-driven frameworks, Explainable AI (SHAP analysis), Machine Learning, Evolutionary Algorithms |

| Material Developed | Multiple Principal Element Alloys (MPEAs) |

| Key Properties | Superior strength, toughness, thermal stability, corrosion resistance |

| Applications | Medical implants, aircraft components, catalytic converters, renewable energy |

| Traditional Approach | Slow, trial-and-error experimentation |

| AI Approach | Predictive, interpretable, and efficient alloy design |

| Published In | Nature’s npj Computational Materials |

| Funding | National Science Foundation |

| Official Source | Virginia Tech News |

The development of metallic materials using data-driven frameworks and explainable AI is a watershed moment for science and industry. By combining vast datasets, advanced machine learning, and transparent AI tools, researchers are designing alloys that are stronger, more durable, and better suited to the challenges of tomorrow. This approach not only saves time and money but also deepens our understanding of the fundamental science behind materials, paving the way for innovations that will shape our world for decades to come.

Understanding Multiple Principal Element Alloys (MPEAs)

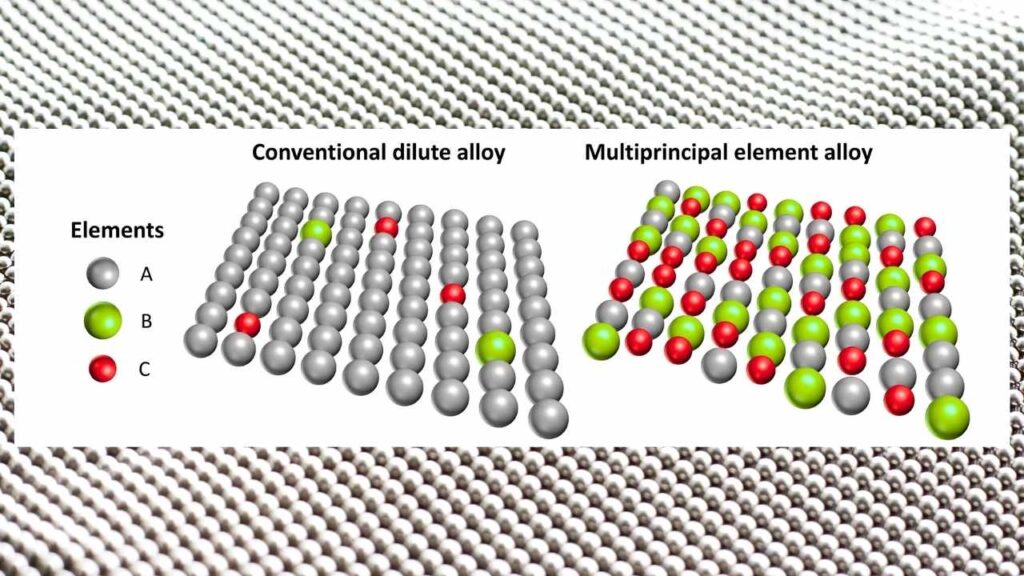

What Are MPEAs?

Multiple Principal Element Alloys (MPEAs), also known as high-entropy alloys (HEAs), are metals made by mixing three or more main elements in nearly equal amounts. Unlike traditional alloys, which typically have one main element (like iron in steel), MPEAs get their unique properties from the complex interactions among several different metals.

Why Are MPEAs Important?

- Enhanced Strength and Toughness: MPEAs can be engineered to be much stronger and tougher than conventional alloys, making them ideal for demanding applications.

- Thermal Stability: They maintain their properties even at very high temperatures, which is crucial for jet engines and power plants.

- Corrosion Resistance: MPEAs can resist rust and chemical attack, extending the life of critical components.

- Design Flexibility: The ability to mix and match elements allows scientists to tailor alloys for specific needs.

Real-World Examples

- Medical Implants: MPEAs are being explored for use in joint replacements and bone plates due to their biocompatibility and durability.

- Aerospace: Their strength-to-weight ratio makes them attractive for aircraft and spacecraft parts.

- Energy: Used in turbines and reactors where extreme conditions demand exceptional materials.

The Traditional Approach: Why It’s Slow and Expensive

For over a century, new alloys were discovered through trial and error. Scientists would:

- Mix different metals in various proportions.

- Test each combination for strength, hardness, corrosion resistance, etc.

- Analyze results and repeat the process, often for years.

Limitations:

- Time-Consuming: With thousands of possible combinations, only a handful could be tested in a reasonable timeframe.

- Resource-Intensive: Each test requires expensive materials, specialized equipment, and skilled labor.

- Limited Insight: Often, scientists knew what worked but not always why, making it hard to improve or predict results.

According to a 2020 review in Science, the average time from alloy concept to commercial use can exceed 20 years.

The Breakthrough: Data-Driven Frameworks and Explainable AI

What Is a Data-Driven Framework?

A data-driven framework uses large datasets—combining past experiments, computer simulations, and theoretical models—to guide decisions. Instead of relying on intuition or luck, scientists can make informed choices based on evidence.

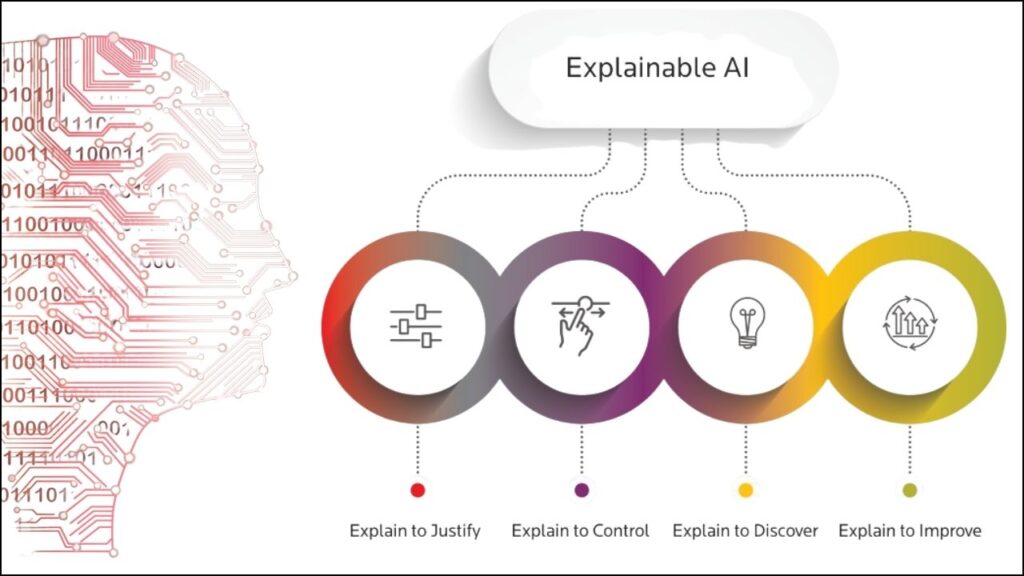

How Does Explainable AI Work in Materials Science?

Artificial intelligence (AI), especially machine learning, can analyze massive datasets and spot patterns humans might miss. But traditional AI often acts as a “black box”—giving answers without explanations.

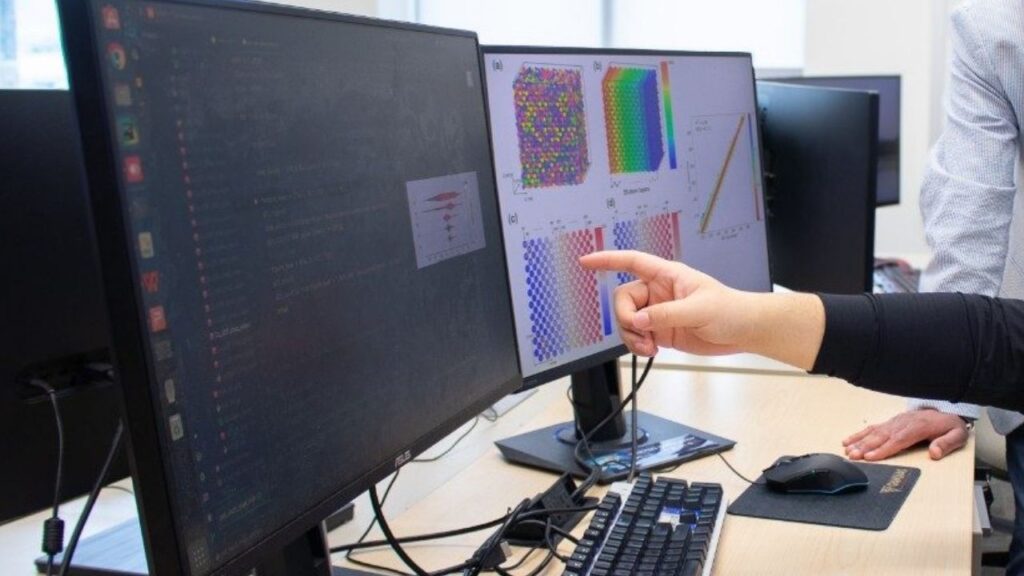

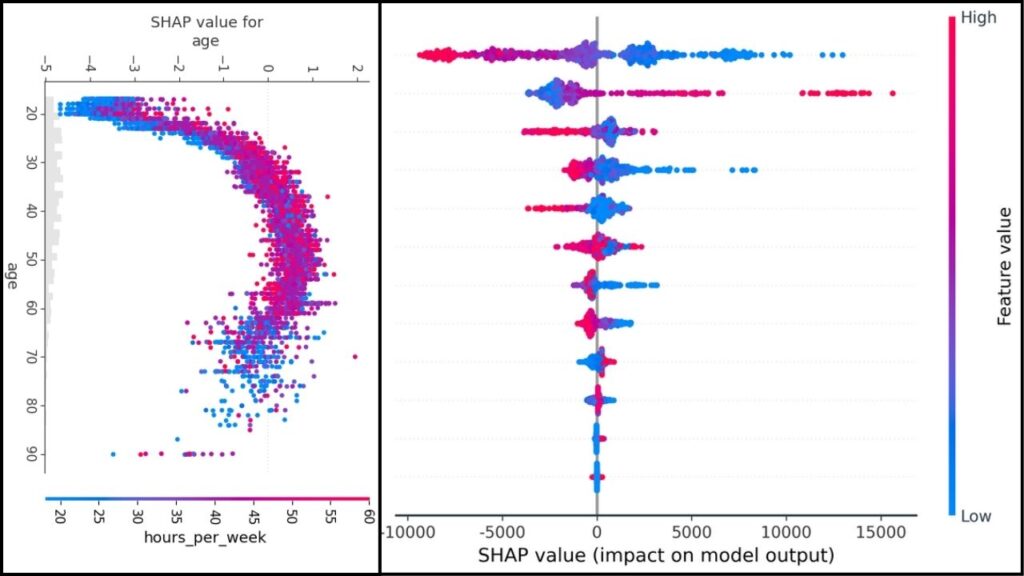

Explainable AI (XAI) changes this by showing why it makes certain predictions. The Virginia Tech team used a technique called SHAP (SHapley Additive exPlanations) analysis, which helps scientists see which elements and atomic features most influence an alloy’s properties.

Why Is This Important?

- Trust: Scientists and engineers can trust AI recommendations because they understand the reasoning.

- Discovery: XAI can reveal new scientific principles, not just solutions.

- Efficiency: By focusing on the most promising candidates, researchers save time and resources.

Step-by-Step: How AI Designs New Metallic Materials

1. Building the Dataset

Researchers compile data from:

- Historical experiments on thousands of alloys.

- High-fidelity simulations that predict how atoms behave under stress.

- Physical measurements like strength, ductility, and corrosion resistance.

This data is carefully cleaned and validated to ensure accuracy.

2. Training the Machine Learning Model

Using advanced algorithms, the AI learns relationships between alloy composition, atomic structure, and material properties. It can then predict how new combinations might perform—often with over 90% accuracy, according to peer-reviewed studies.

3. Predicting and Optimizing Alloys

The AI suggests new recipes for MPEAs likely to have the desired properties. For example, if a company needs a metal that’s both lightweight and corrosion-resistant, the AI can recommend specific element ratios.

Researchers also use evolutionary algorithms—which mimic natural selection—to refine these recipes, improving performance generation by generation.

4. Explainability with SHAP Analysis

SHAP analysis breaks down the AI’s predictions, showing which elements and atomic features are most important. This helps scientists:

- Understand why certain alloys work.

- Discover new rules for alloy design.

- Communicate findings to regulators, manufacturers, and other stakeholders.

5. Experimental Validation

The most promising alloys are synthesized in the lab and tested. In the Virginia Tech project, lab results closely matched AI predictions, confirming the reliability of the approach.

Real-World Applications: Transforming Industries

Medicine

- Joint Replacements: MPEAs can last longer and cause fewer allergic reactions.

- Bone Plates: Improved strength and compatibility reduce the risk of failure.

Aerospace

- Aircraft Components: Lighter, stronger metals mean safer, more fuel-efficient planes.

- Spacecraft: MPEAs can withstand extreme temperatures and radiation.

Energy

- Turbines: Enhanced durability reduces maintenance costs and downtime.

- Renewable Energy: Corrosion-resistant alloys extend the life of wind and solar equipment.

Automotive

- Catalytic Converters: Better alloys mean cleaner emissions and longer-lasting parts.

- Electric Vehicles: Lightweight, high-strength alloys improve range and safety.

The Value of Explainable AI: Beyond the Black Box

Explainable AI is not just a buzzword—it’s a necessity for critical industries. Here’s why:

- Regulatory Compliance: Medical and aerospace products must meet strict safety standards. XAI helps prove that new materials are safe and reliable.

- Faster Innovation: By understanding why materials work, companies can innovate faster and more confidently.

- Workforce Development: Engineers and scientists with XAI skills are in high demand, opening new career paths.

According to a 2024 industry report, companies using explainable AI in R&D saw a 30% reduction in time-to-market for new products.

Practical Advice: How to Get Involved

For Students

- Learn the Basics: Study chemistry, physics, and computer science.

- Explore AI Tools: There are many free resources to learn machine learning.

- Stay Curious: Ask questions about why things work, not just how.

For Professionals

- Adopt Data-Driven Methods: Use AI to screen materials before physical testing.

- Collaborate: Work with data scientists and AI experts to enhance your R&D.

- Invest in Training: Upskill your team in AI and explainable methods.

For Companies

- Invest in AI Infrastructure: The upfront cost pays off in faster, better innovation.

- Focus on Transparency: Choose tools that provide clear explanations, not just predictions.

- Partner with Universities: Collaborate on research and talent development.

Scientists Extend Quantum State Lifetimes Using Laser Pulses — A Major Leap for Quantum Tech

NASA’s SPHEREx Telescope Launches to Explore Universe’s Origins

FAQs About Researchers Develop Metallic Materials Using Data-Driven Frameworks and Explainable AI

Q1: What are the main benefits of MPEAs over traditional alloys?

A: MPEAs offer superior strength, toughness, and corrosion resistance. Their unique atomic structure allows for properties that are difficult or impossible to achieve with traditional alloys.

Q2: How accurate are AI predictions in materials science?

A: With high-quality data, machine learning models can predict alloy properties with over 90% accuracy, as validated by experimental results.

Q3: Is explainable AI only useful for scientists?

A: No. XAI benefits everyone from engineers and regulators to business leaders by providing transparency and building trust in AI-driven decisions.

Q4: Can this approach be used for non-metallic materials?

A: Absolutely. The same principles apply to polymers, ceramics, and even biological materials, opening doors to new discoveries in many fields.

Q5: Where can I find more information?

A: For official updates, visit the Virginia Tech News link in the Key Highlights table above.