Frontier Supercomputer Runs 5 Million Simulations: Imagine building airplanes, cars, or even bicycles with a material that is stronger than steel but lighter than aluminum. This isn’t science fiction—it’s the promise of carbon fiber, a material that’s already revolutionizing industries from aerospace to sports. But what if we could make carbon fiber even stronger, lighter, and more affordable? Thanks to the Frontier supercomputer at Oak Ridge National Laboratory (ORNL), that future is closer than ever.

In 2025, scientists at ORNL harnessed the power of Frontier—the world’s most powerful open-science supercomputer—to run 5 million atom-level simulations. Their goal? To discover how to make carbon fiber composites not just better, but extraordinary. This article will guide you through their journey, explain why it matters, and show how supercomputing is shaping the materials of tomorrow.

Frontier Supercomputer Runs 5 Million Simulations

| Feature/Stat | Details |

|---|---|

| Supercomputer Used | Frontier at Oak Ridge National Laboratory |

| Peak Performance | 2 exaflops (2 quintillion calculations/second) |

| Atoms Simulated | 5 million |

| Material Focus | Carbon fiber composites with PAN nanofiber reinforcement |

| Simulation Technique | Molecular dynamics using LAMMPS |

| Key Discovery | PAN nanofibers (~6 nanometers) dramatically improve strength and load distribution |

| Applications | Aerospace, automotive, manufacturing, sports equipment |

| Cost & Time Savings | Reduces need for expensive, time-consuming physical experiments |

| Official Resource | Oak Ridge Leadership Computing Facility |

The work done on the Frontier supercomputer is a game-changer for the world of materials science. By simulating 5 million atoms, ORNL researchers discovered exactly how to make carbon fiber composites that are not only stronger and lighter but also more cost-effective. This breakthrough will ripple across industries, making products safer, more efficient, and more affordable. With supercomputers like Frontier, the future of materials is brighter—and stronger—than ever.

What is Carbon Fiber and Why Is It Important?

Carbon fiber is a material made from thin strands of carbon atoms, each much thinner than a human hair. When these strands are woven together and set in a plastic (called a polymer matrix), the result is a composite that’s both incredibly strong and very light. That’s why it’s used in:

- Airplane wings and fuselages

- Race cars and luxury vehicles

- High-end bicycles and sporting goods

- Wind turbine blades

But even with all its strengths, carbon fiber composites have a weak spot: the interface—the area where the carbon fibers meet the surrounding plastic. This is often where cracks start and materials fail.

How Did ORNL Make Carbon Fiber Stronger?

The Challenge: Making a Strong Bond

Think of carbon fiber like a bundle of spaghetti in glue. The spaghetti (carbon fibers) is strong, but if the glue (polymer) doesn’t stick well, the bundle falls apart. The key to a better material is making the glue and spaghetti bond as tightly as possible.

The Breakthrough: PAN Nanofibers

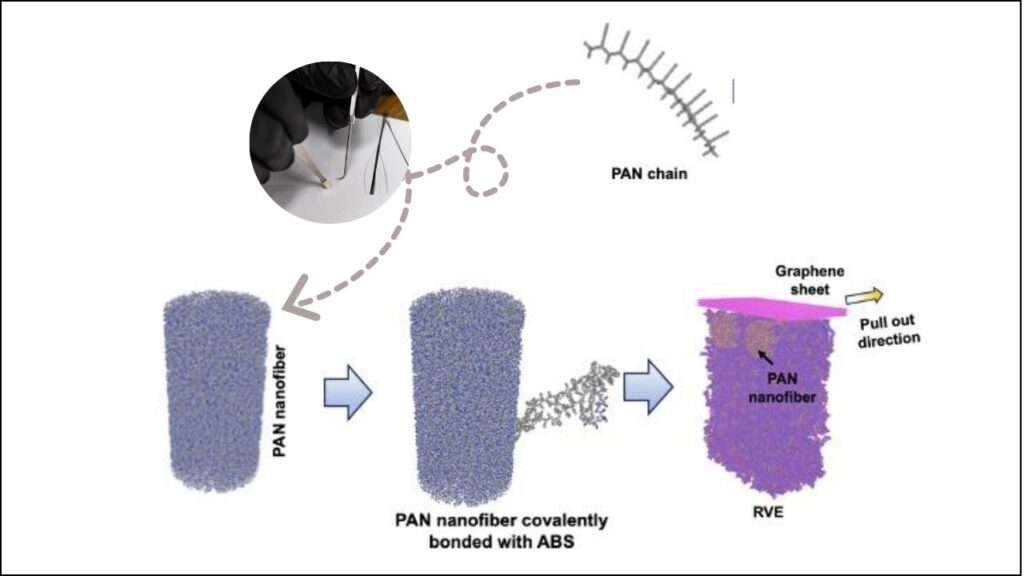

The ORNL team used a special nanomaterial called polyacrylonitrile nanofibers (PAN nanofibers). These are tiny fibers, just 6 to 10 nanometers wide (for comparison, a sheet of paper is about 100,000 nanometers thick). Using a process called electrospinning—where an electric field and spinning drum create ultra-fine fibers—they added a layer of PAN nanofibers at the interface between the carbon fibers and the polymer.

Why PAN Nanofibers?

These nanofibers act like a super-strong Velcro, helping the carbon fibers and polymer stick together better. This means the material can handle more stress before breaking, making it stronger and more reliable.

The Power of Supercomputing: Why Frontier Was Essential

Why Not Just Test in Real Life?

Building and testing new carbon fiber composites in the lab is very expensive and takes a lot of time. Each experiment requires new materials, specialized equipment, and careful measurements. Plus, you can only test a few ideas at a time.

Enter Frontier: The World’s Most Powerful Supercomputer

Frontier is a supercomputer capable of over 2 exaflops—meaning it can do over two quintillion calculations every second. That’s a 2 followed by 18 zeros! With this power, scientists can simulate the behavior of millions of atoms at once, something no regular computer can do.

What Did the Simulations Show?

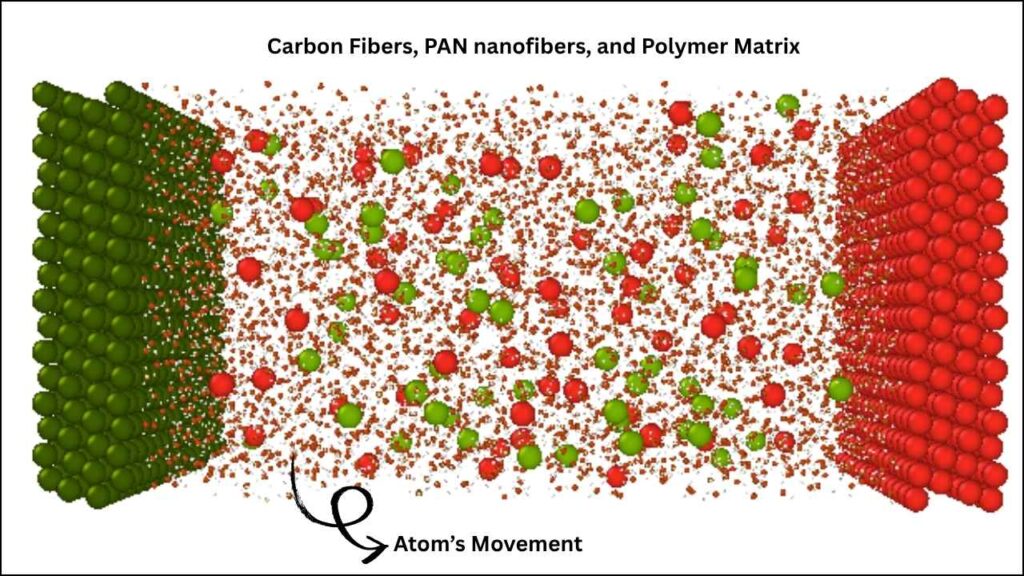

- The team created a virtual model of a carbon fiber composite with 5 million atoms—by far the largest, most detailed simulation of its kind.

- They tested different PAN nanofiber sizes and found that fibers about 6 nanometers wide worked best. These fibers aligned perfectly at the interface, improving both strength and the way stress is shared between the fibers and the polymer.

How is This Different from Past Research?

Most previous simulations could only handle a few thousand atoms and had to make lots of guesses, grouping atoms together to save time. Frontier let the team simulate every atom individually, giving them a much clearer and more accurate picture.

Step-by-Step: How the Simulations Worked

1. Building the Model

- Scientists used LAMMPS (Large-scale Atomic/Molecular Massively Parallel Simulator), a special code for modeling how atoms move and interact.

- They built a digital “sandwich” of carbon fibers, PAN nanofibers, and polymer matrix.

2. Running the Simulations

- The model was run on Frontier, tracking the position and behavior of 5 million atoms as stress was applied.

- The computer calculated how the materials stretched, bent, and broke at the atomic level.

3. Analyzing the Results

- The team compared how different nanofiber sizes affected the bond.

- They found that 6-nanometer PAN nanofibers gave the best results, improving both strength and durability.

4. Real-World Impact

- These insights can now guide manufacturers in making better carbon fiber composites—without wasting time and money on trial-and-error experiments.

Why This Matters: Real-World Applications

Aerospace and Aviation:

Planes made with these new carbon fiber composites could be lighter, use less fuel, and be safer.

Automotive Industry:

Cars could be made stronger and lighter, improving speed and fuel efficiency.

Sports Equipment:

Bikes, tennis rackets, and golf clubs could be more durable and high-performing.

Manufacturing:

Any industry that needs tough, lightweight materials could benefit from this breakthrough.

PsiQuantum Study Reveals Roadmap For Loss-Tolerant Photonic Quantum Computing

Marvell Says Future of Cloud Computing Depends on Custom-Built Silicon Chips

Google Research Warns Quantum Computing Could Crack Bitcoin Encryption Sooner Than Expected

FAQs About Frontier Supercomputer Runs 5 Million Simulations

What is the Frontier supercomputer?

Frontier is the world’s fastest open-science supercomputer, located at Oak Ridge National Laboratory in the USA. It can perform over 2 exaflops (2 quintillion calculations per second).

What are PAN nanofibers?

PAN nanofibers are ultra-thin fibers made from polyacrylonitrile, a type of plastic. They’re only a few nanometers wide and help strengthen carbon fiber composites by improving the bond between fibers and polymer.

Why can’t regular computers do these simulations?

Simulating millions of atoms in detail requires enormous computing power. Regular computers can only handle thousands of atoms and must use shortcuts, which can make results less accurate.

How does this research help industry?

It gives manufacturers a “blueprint” for making stronger, lighter, and more cost-effective carbon fiber materials. This can lead to better products in aerospace, automotive, sports, and more.

Practical Advice: What This Means for Professionals

- Materials Scientists: Use these findings to design new composites with better interfaces, focusing on nanofiber reinforcement.

- Engineers: Expect stronger, lighter materials for design, leading to more efficient structures and vehicles.

- Manufacturers: Reduce R&D costs by using simulation data to focus physical testing on the most promising material combinations.

- Students and Educators: Study this as a model of how supercomputing and materials science can work together to solve real-world problems.