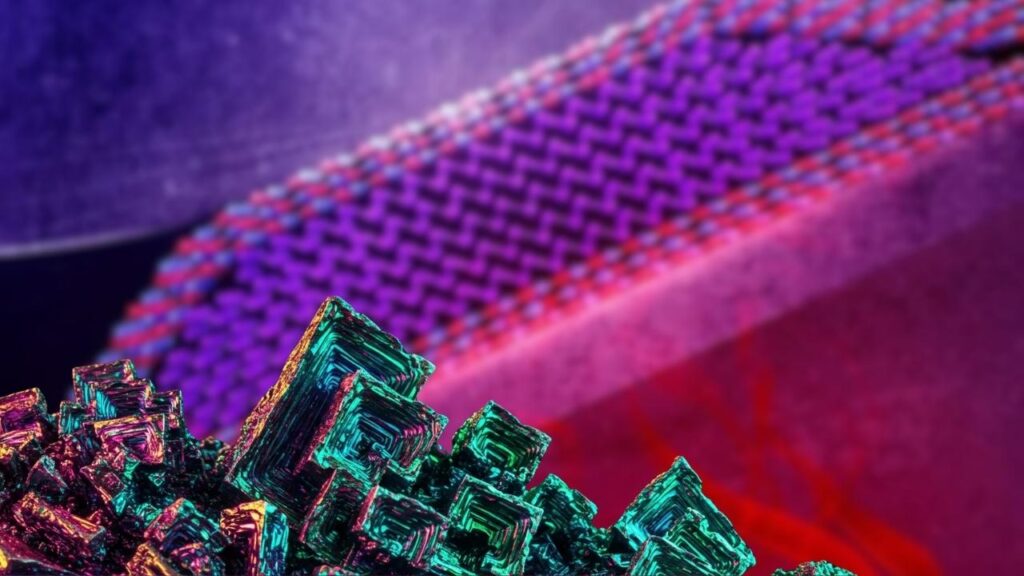

New Method to Stabilize Ultra-Thin Materials: The world of electronics is changing fast, and one of the most exciting developments is the discovery of new methods to stabilize ultra-thin materials for next-gen electronics.

These advancements are not only making our devices smaller and faster but are also opening doors to entirely new technologies, from quantum computers to wearable sensors. In this article, we’ll break down what these ultra-thin materials are, why stabilizing them is so important, and how the latest breakthroughs could shape the future of technology.

New Method to Stabilize Ultra-Thin Materials

| Topic/Keyword | Key Data & Stats | Practical Impact |

|---|---|---|

| Ultra-Thin Materials | Niobium phosphide outperforms copper at <5 nm thickness | Enables faster, more energy-efficient chips |

| 2D Ferroelectric Memory | Stable, reversible polarization in h-BN/graphene | Paves way for AI hardware, wafer-scale memory |

| Ultra-Thin Magnets | 20% stronger, stable at higher temperatures | Key for quantum computing, advanced comms |

| Flexible Electronics | Strain-free vanadium dioxide films on hBN | Flexible, adaptable devices for wearables |

| Ultra-Thin Bismuth | Stable electrical effect from -273°C to room temp | Reliable components for extreme environments |

The discovery of new methods to stabilize ultra-thin materials for next-gen electronics marks a turning point in the evolution of technology. From super-thin wires that outperform copper to flexible films for wearable tech and ultra-stable memory for AI, these breakthroughs are setting the stage for a smarter, more efficient, and more adaptable digital world. By staying informed and engaged, both professionals and curious minds can be part of this exciting revolution.

What Are Ultra-Thin Materials?

Ultra-thin materials are substances that are only a few atoms or molecules thick. Imagine slicing a piece of paper until it’s so thin you can barely see it—now imagine slicing it another thousand times! These materials, often called “2D materials,” include famous examples like graphene, as well as newer discoveries such as niobium phosphide, ultra-thin bismuth, and vanadium dioxide.

Why Are Ultra-Thin Materials Important?

- Miniaturization: As electronics get smaller, we need materials that can still do their job even when they’re incredibly thin.

- Performance: Many ultra-thin materials have unique electrical, magnetic, or optical properties that can’t be found in bulkier substances.

- Energy Efficiency: Thinner wires and components can mean less wasted energy and cooler, longer-lasting devices.

The Challenge: Stability at the Atomic Scale

While ultra-thin materials are promising, they come with a big challenge: stability. When materials get very thin, their properties can change or become unpredictable. For example, a wire that conducts electricity perfectly when it’s thick might lose that ability when it’s only a few atoms wide. This instability has been a major roadblock for using these materials in real-world electronics.

Breakthrough #1: Super-Thin Conductors for Nanoelectronics

A team at Stanford University has discovered that niobium phosphide can conduct electricity better than copper when it’s just a few atoms thick. This is a huge deal because copper, the standard in electronics, starts to lose its effectiveness at ultra-small scales.

How does it work?

- Niobium phosphide belongs to a group called topological semimetals, which have surfaces that conduct electricity better than their interiors.

- When made ultra-thin, the surface takes over, allowing electricity to flow even more easily than in copper.

- Even better, these films can be made at lower temperatures, making them compatible with today’s chip manufacturing.

Why does it matter?

- Faster, more efficient chips for everything from smartphones to massive data centers.

- Less wasted energy means cooler devices and lower electricity bills for big tech companies.

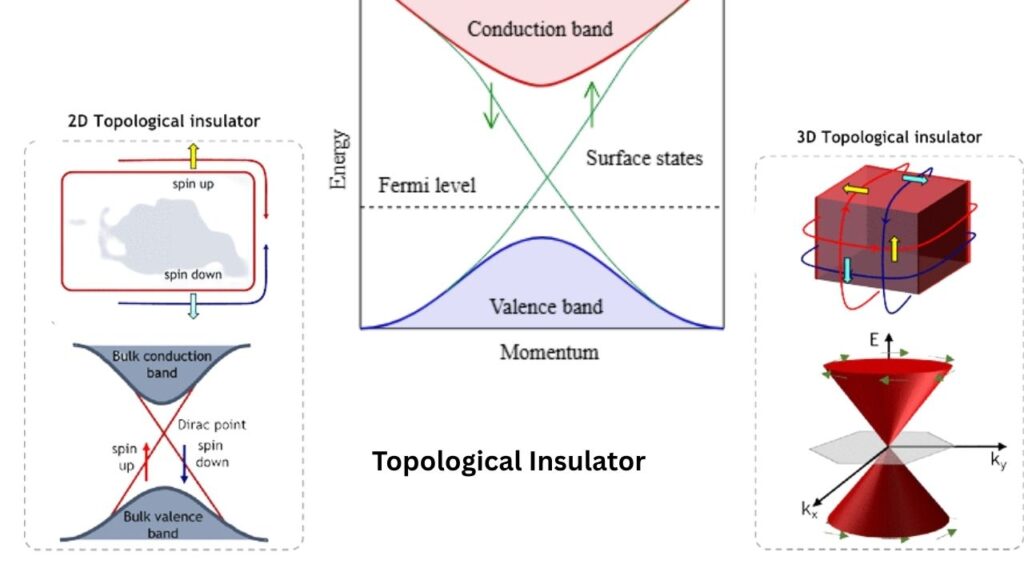

Breakthrough #2: Ultra-Thin Magnets Strengthened by Topological Insulators

Magnets are crucial for memory storage and advanced computing, but traditional magnets can’t be miniaturized easily. Ultra-thin magnets, just a few atoms thick, could change that—if they could work at practical temperatures.

A University of Ottawa-led team found that layering ultra-thin magnets with a special material called a topological insulator boosts their magnetic strength by 20% and keeps them stable at higher temperatures. This is a major step toward using these magnets in real-world devices, not just in labs.

How does it work?

- Topological insulators allow electrons to move smoothly along their surfaces.

- When combined with ultra-thin magnets, they stabilize the magnetism, making it stronger and more reliable.

Why does it matter?

- Enables smaller, more powerful electronics, including quantum computers and advanced communication systems.

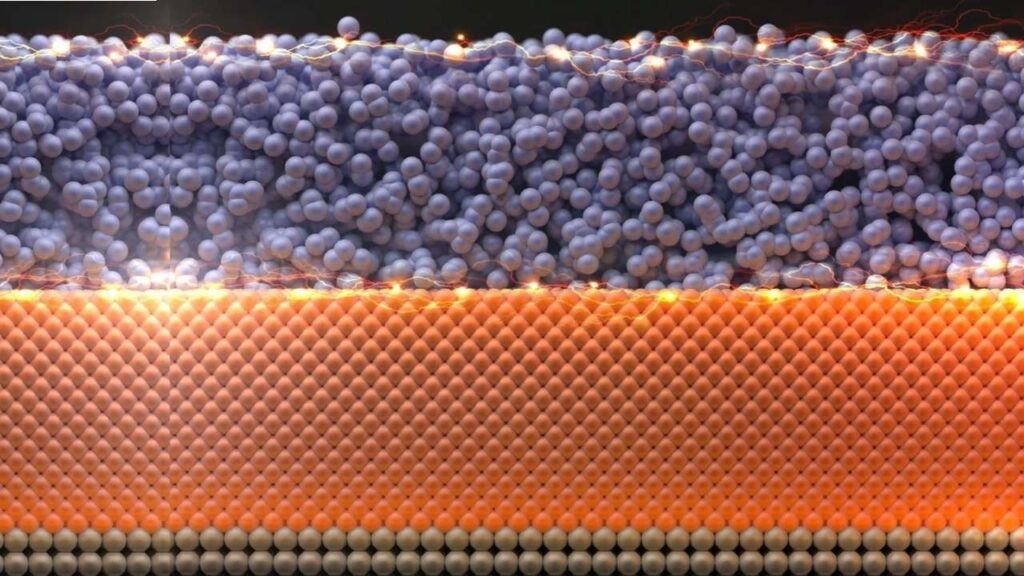

Breakthrough #3: Flexible, Stable Ultra-Thin Films for Wearable Tech

Imagine electronics that can bend, stretch, or even stick to your skin. That’s the promise of flexible electronics. But making ultra-thin films that stay stable when bent or stretched is tough.

A team led by Osaka University created ultra-thin films of vanadium dioxide on a soft, two-dimensional material called hexagonal boron nitride (hBN). This method preserves the film’s unique ability to switch between conducting and insulating states, even when it’s just 12 nanometers thick.

How does it work?

- Growing vanadium dioxide on hBN avoids the strain and damage caused by harder surfaces.

- The result is a film that keeps its special properties, even when flexed.

Why does it matter?

- Paves the way for smart, adaptable devices that can be worn or integrated into clothing.

Breakthrough #4: Ultra-Thin Bismuth for Green Electronics

Stability isn’t just about keeping things working—it’s also about handling extreme conditions. A McGill University team discovered that ultra-thin bismuth can maintain a mysterious electrical effect across a huge temperature range, from -273°C to room temperature. This could lead to electronics that work reliably in even the harshest environments.

How does it work?

- The atomic structure of bismuth seems to constrain electrons in a way that mimics exotic materials called topological materials.

- This effect could be harnessed for reliable, energy-efficient devices.

Why does it matter?

- Opens new possibilities for electronics in space, deep-sea exploration, or other extreme settings.

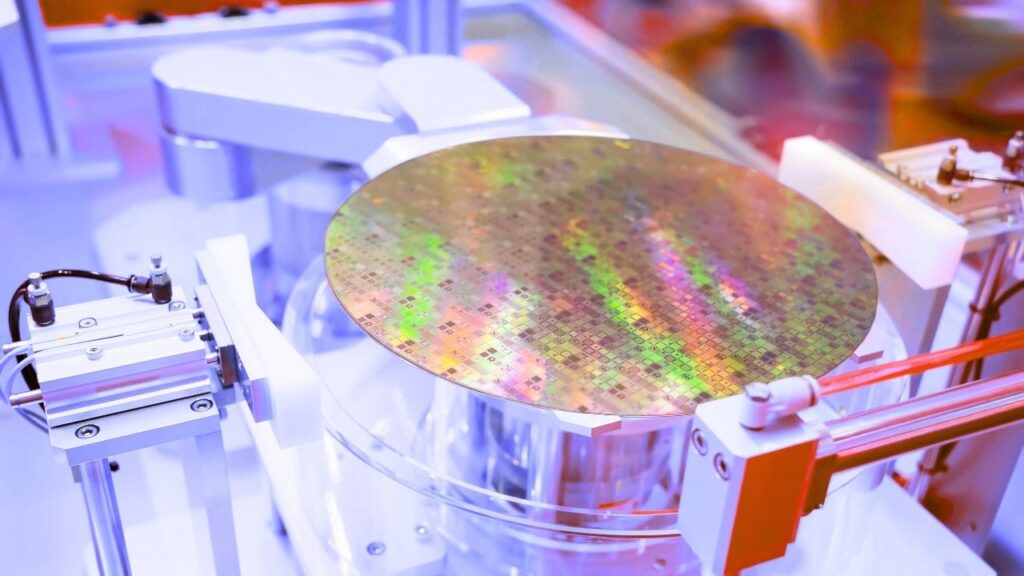

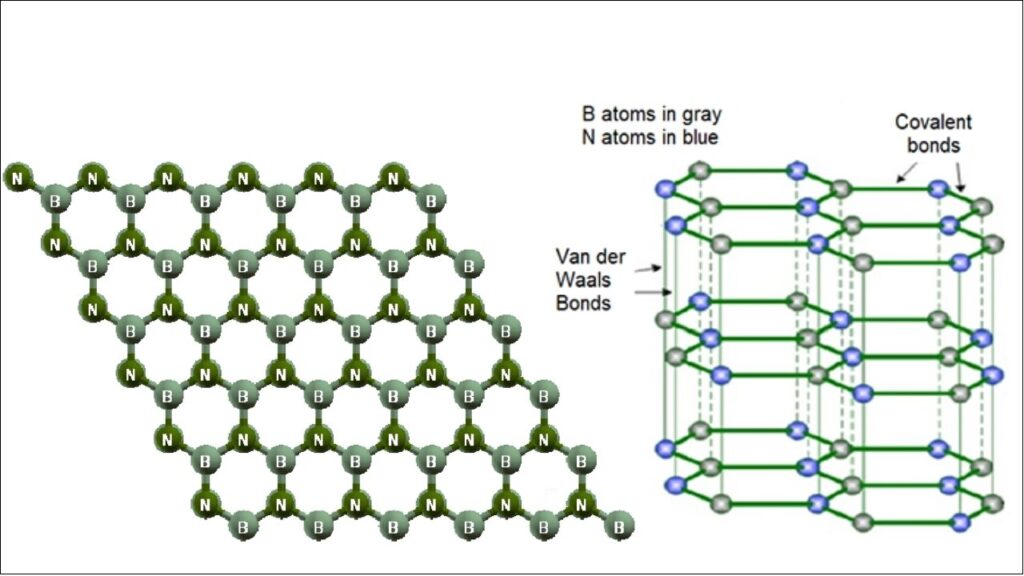

Breakthrough #5: Wafer-Scale 2D Ferroelectric Memory

Memory is at the heart of every electronic device. Researchers in Taiwan developed a method to grow wafer-scale, ultra-thin ferroelectric memory using layers of hexagonal boron nitride (h-BN) on graphene. This memory is not only ultra-thin but also stable and reversible, making it ideal for future AI hardware and high-speed computing.

How does it work?

- Plasma-assisted molecular beam epitaxy allows precise control over the stacking of h-BN and graphene.

- The result is a memory device with robust, switchable polarization—key for storing data efficiently.

Why does it matter?

- Enables new types of memory that are faster, use less power, and can be integrated into advanced chips for AI and machine learning.

How These Breakthroughs Will Shape the Future

These discoveries are more than just scientific curiosities—they have real-world implications for how we live, work, and play.

For Everyday Users

- Longer battery life in phones and laptops

- Faster, more reliable devices

- Flexible gadgets that can be worn or integrated into clothing

For Professionals and Industry

- Data centers that use less power and generate less heat

- Advanced computing for AI, quantum tech, and scientific research

- New markets for wearable tech, smart sensors, and green electronics

Practical Advice: How to Stay Ahead in the Ultra-Thin Materials Revolution

Whether you’re a student, engineer, or tech enthusiast, here are some steps to stay informed and prepared:

- Follow trusted sources: Keep up with leading universities and research labs.

- Learn the basics of 2D materials: Explore introductory resources and educational materials.

- Experiment with simulations: Many breakthroughs are confirmed with computer models—learning basic simulation tools can be a big advantage.

- Watch for new applications: From AI chips to wearable health monitors, ultra-thin materials are showing up in more products every year.

- Network with professionals: Join conferences or online forums focused on nanotechnology and materials science.

AI Helps Decode Hard‑To‑Read Proteins, Boosting Biological Research

Breakthrough in Electron Microscopy Captures Individual Nanoparticles with Unprecedented Precision

FAQs About New Method to Stabilize Ultra-Thin Materials

Q: What are ultra-thin materials?

A: Ultra-thin materials are substances just a few atoms or molecules thick, often called 2D materials. They have unique properties that make them valuable for electronics and other high-tech applications.

Q: Why do we need to stabilize ultra-thin materials?

A: As materials get thinner, their properties can change or become unstable. Stabilizing them ensures they work reliably in real-world devices.

Q: How will these breakthroughs affect my everyday devices?

A: Expect faster smartphones, longer battery life, and new types of flexible or wearable gadgets as these materials are adopted.

Q: Are these materials safe and environmentally friendly?

A: Many ultra-thin materials, like bismuth and vanadium dioxide, are being studied for their potential in green electronics and energy-efficient devices.

Q: Where can I learn more?

A: Check out official university news pages, scientific journals, and trusted science news outlets for the latest updates.