Shape-Shifting Electronic Ink: Imagine a world where your smartwatch can bend and twist just like a rubber band, or where medical implants inside your body can soften to avoid discomfort—all thanks to a special kind of electronic ink. This isn’t science fiction; it’s the reality being created by scientists at KAIST and Seoul National University in South Korea. Their latest breakthrough—shape-shifting electronic ink—could revolutionize how we use and interact with technology, making gadgets and medical devices more adaptable, comfortable, and powerful than ever before.

At its core, this new electronic ink is made from a metal called gallium. Gallium is a bit of a shape-shifter itself—it’s solid at room temperature but melts into a soft liquid just below human body temperature. By mixing tiny gallium particles with a special polymer-based solvent, researchers have created an ink that can be printed onto surfaces to form electronic circuits. These circuits can switch between being as hard as plastic or as soft as rubber, simply by changing the temperature. This means devices made with this ink can be rigid and sturdy when needed, then soft and flexible when comfort or adaptability is required.

Shape-Shifting Electronic Ink

| Feature | Details |

|---|---|

| Main Material | Gallium with polymer-based solvent (DMSO, hydrophilic polyurethane) |

| State Change Trigger | Temperature (heating/cooling) |

| Printing Resolution | As small as 50 micrometers (thinner than a human hair) |

| Key Applications | Medical implants, wearable electronics, robotics, flexible devices |

| Scalability | Room-temperature printing, compatible with conventional manufacturing |

| Research Team | KAIST (Jae-Woong Jeong, Steve Park), Seoul National University (Seongjun Park) |

| Official Reference | KAIST News Center |

Shape-shifting electronic ink is a game-changer for the future of flexible electronics. By combining the unique properties of gallium with advanced polymer chemistry, scientists have created an ink that can be printed at room temperature and can switch between rigid and soft states on demand. This opens up exciting possibilities for medical devices, wearables, robotics, and personal electronics—making our gadgets more adaptable, comfortable, and powerful than ever before.

What Is Shape-Shifting Electronic Ink?

Shape-shifting electronic ink is a special kind of material that can be printed or drawn onto surfaces to create electronic circuits. Unlike regular ink, which just sits on paper, this ink is made from gallium, a metal that changes its state from solid to liquid when it gets a little warm—just below your body temperature.

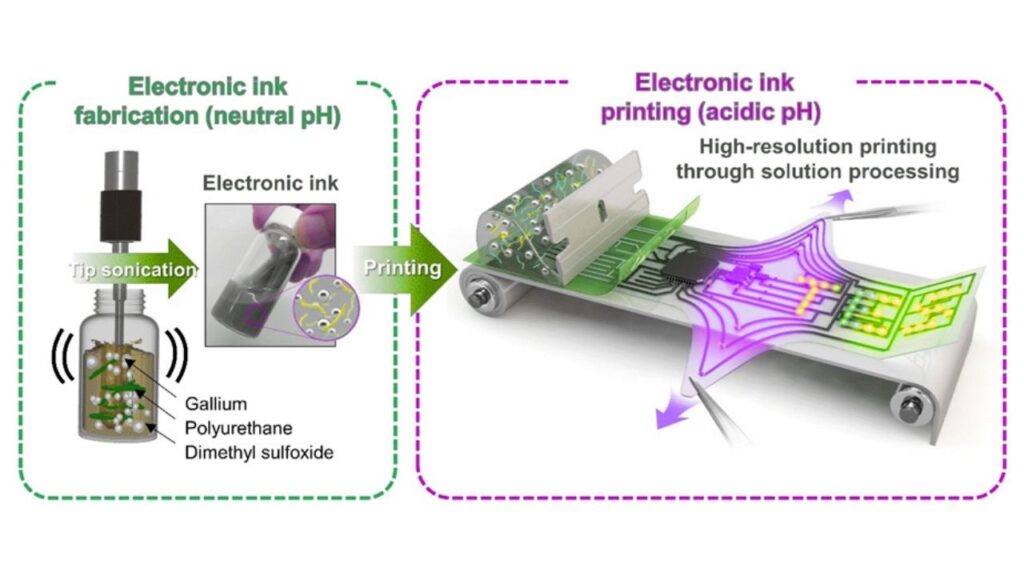

Scientists have long wanted to use gallium in electronics because of this unique property. However, gallium has some tricky behaviors: it tends to form droplets and can be unstable when it’s liquid, making it hard to control. The research team solved this problem by mixing gallium with a neutral solvent (like DMSO) and a polymer, creating a stable ink that can be printed at room temperature.

When the printed circuit is heated, the solvent becomes slightly acidic, which helps remove a thin oxide layer on the gallium particles. This allows the particles to melt and merge, forming highly conductive pathways—meaning electricity can flow smoothly through the circuit.

How Does It Work? A Step-by-Step Guide

Let’s break down how shape-shifting electronic ink works, step by step:

- Material Preparation

- Gallium particles are mixed with a neutral solvent (like DMSO) and a hydrophilic polymer.

- This creates a stable, printable ink with gallium evenly spread throughout.

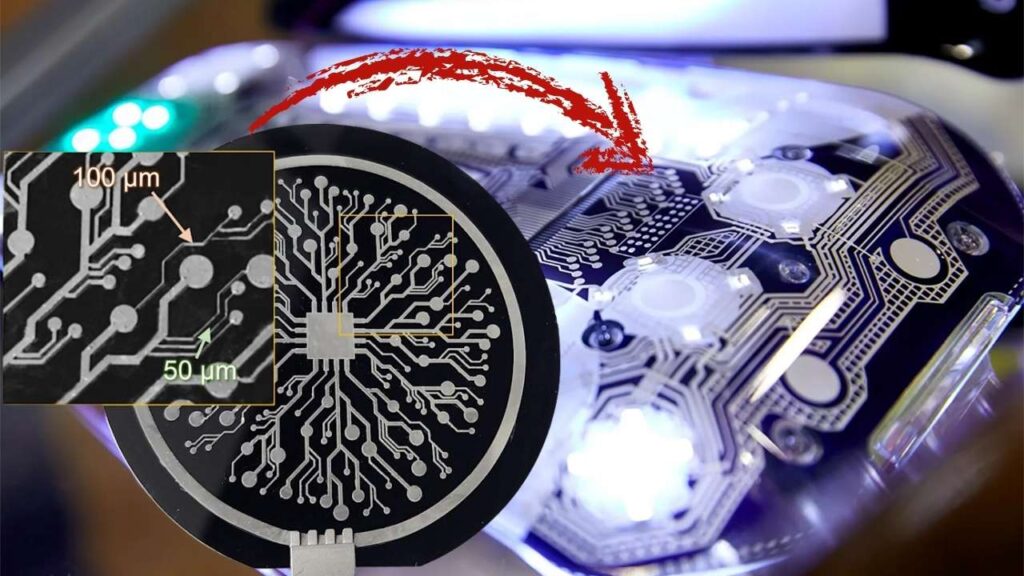

- Room-Temperature Printing

- The ink can be printed onto surfaces using regular printing methods.

- The circuits can be made very small—some features are as tiny as 50 micrometers, which is thinner than a human hair.

- Heating and Softening

- When the printed circuit is heated (for example, by body heat), the solvent becomes acidic.

- This acidity removes the oxide layer on the gallium, letting the particles melt and merge.

- The circuit becomes soft and flexible, like rubber.

- Cooling and Hardening

- When the temperature drops, the gallium solidifies again.

- The circuit becomes rigid, like plastic.

- Repeatable Switching

- This process can be repeated many times—heat to soften, cool to harden.

- The circuit stays functional and reliable through many cycles.

Why Is This Important?

Most electronics today are either rigid (like smartphones and laptops) or soft (like fitness trackers and smart fabrics). Rigid devices are strong and reliable, but they can’t bend or adapt. Soft devices are comfortable and flexible, but they can be harder to make and may not be as durable or precise.

Shape-shifting electronic ink bridges this gap. It allows devices to be both rigid and soft, depending on what’s needed. This opens up exciting possibilities for:

- Medical Implants: Devices that are hard and easy to insert, then soften inside the body to avoid discomfort or damage to tissues.

- Wearable Electronics: Smartwatches, fitness trackers, or even clothing that can bend and flex with your movements, then become rigid when needed for protection or precision.

- Robotics: Robots with parts that can switch between rigid and soft states, making them safer to interact with and more adaptable to different tasks.

- Personal Electronics: Gadgets that combine the durability of rigid electronics with the comfort and flexibility of soft materials.

Practical Examples and Applications

Let’s look at some real-world examples to make this technology easier to understand:

- Medical Implants: Imagine a tiny device that doctors put inside your body to monitor your health. With shape-shifting electronic ink, the device could be hard and easy to insert, then soften inside your body to avoid discomfort or damage to your tissues.

- Wearable Devices: A smartwatch made with this ink could be rigid and sturdy when you’re not wearing it, then become soft and flexible when you put it on your wrist, making it more comfortable to wear all day.

- Robotics: Robots could have hands or arms that are rigid for heavy lifting, then soften to gently pick up delicate objects like eggs or fruit.

- Flexible Electronics: Future gadgets could be folded, rolled up, or even stretched without breaking, thanks to circuits that can change their stiffness on demand.

Who Is Behind This Innovation?

This breakthrough was made by a team of scientists from KAIST (Korea Advanced Institute of Science and Technology) and Seoul National University. The project was led by Professor Jae-Woong Jeong from KAIST’s School of Electrical Engineering, Professor Steve Park from KAIST’s Department of Materials Science and Engineering, and Professor Seongjun Park from Seoul National University.

Their work was published in the prestigious journal Science Advances on May 30, 2025, and has already attracted attention from tech companies and medical device manufacturers around the world.

How Does This Compare to Other Technologies?

To help you understand how shape-shifting electronic ink stands out, here’s a quick comparison:

| Technology | Flexibility | Conductivity | Manufacturing Ease | Key Use Cases |

|---|---|---|---|---|

| Traditional Electronics | Rigid | High | Easy | Smartphones, laptops |

| Soft Electronics | Flexible | Moderate | Hard | Wearables, smart fabrics |

| Shape-Shifting E-Ink | Switchable | High (when soft) | Easy (room temp) | Implants, wearables, robotics |

As you can see, shape-shifting electronic ink combines the best of both worlds: the flexibility of soft electronics and the reliability of rigid electronics, all while being easy to manufacture.

Caltech Unveils New Hybrid Quantum-Classical Computing Method to Revolutionize Chemical Simulations

FAQs About Shape-Shifting Electronic Ink

Q: What is shape-shifting electronic ink made of?

A: It’s made from gallium (a metal that melts just below body temperature), mixed with a neutral solvent and a polymer. This creates a stable, printable ink.

Q: How does the ink change from rigid to soft?

A: When heated, the solvent becomes acidic and removes the oxide layer on the gallium, letting the particles melt and merge. This makes the circuit soft and flexible. When cooled, it becomes rigid again.

Q: What are the main uses for this technology?

A: Medical implants, wearable electronics, robotics, and flexible gadgets are the main applications.

Q: Is this technology safe for medical use?

A: The materials used are biocompatible, and the technology is designed to be safe for use inside the body, but further testing is needed before widespread medical use.

Q: How small can the printed circuits be?

A: The circuits can be printed with features as small as 50 micrometers—thinner than a human hair.

Q: Who developed this technology?

A: A team from KAIST and Seoul National University, led by Professors Jae-Woong Jeong, Steve Park, and Seongjun Park.