SEALSQ Teams Up With Colibritd and Xdigit to Boost Semiconductor Yields: Imagine a world where your phone, car, and even your fridge are powered by tiny, super-smart chips that make everything work better and faster. These chips are called semiconductors, and they’re at the heart of almost every modern gadget. Recently, a major partnership was announced: SEALSQ, ColibriTD, and Xdigit are joining forces to tackle one of the biggest challenges in making these chips—especially at the smallest sizes, less than 7 nanometers (nm). Their goal? To use quantum computing and advanced math to boost the number of good chips made from each batch, making technology more affordable and reliable for everyone.

To understand why this is important, think about baking cookies. If your oven is uneven, some cookies burn and some stay raw. Chip-making is similar: the more “good” chips you get from each wafer (the “batch”), the less you waste and the cheaper each chip becomes. But as chips get smaller, tiny problems—like not enough power reaching every part of the chip—can ruin whole batches. This problem is called IR Drop, and it’s a major headache for chip makers.

SEALSQ Teams Up With Colibritd and Xdigit to Boost Semiconductor Yields

| Key Aspect | Details |

|---|---|

| Partnership | SEALSQ, ColibriTD, Xdigit |

| Goal | Boost semiconductor wafer yields for sub-7nm nodes |

| Main Challenge | IR Drop (voltage loss in power distribution networks) |

| Solution | Quantum computing and advanced mathematical modeling |

| Expected Yield Improvement | Increase from 50% to 80% per wafer |

| Cost Savings | Per-chip costs could be cut by nearly half |

| Development Timeline | Six-month roadmap for proof-of-concept; commercial deployment targeted for 2026 |

| Applications | AI, automotive, IoT, quantum-safe microcontrollers |

| Official Website | SEALSQ |

The partnership between SEALSQ, ColibriTD, and Xdigit is a game-changer for the semiconductor industry. By using quantum computing to solve the tough problem of IR Drop at sub-7nm sizes, they are helping chip makers get more good chips from each wafer, cutting costs, and making technology better for everyone. Whether you’re a kid curious about how gadgets work, a student thinking about a career in tech, or a professional looking for the next big thing, this is a story worth watching.

What Are Semiconductors and Why Do They Matter?

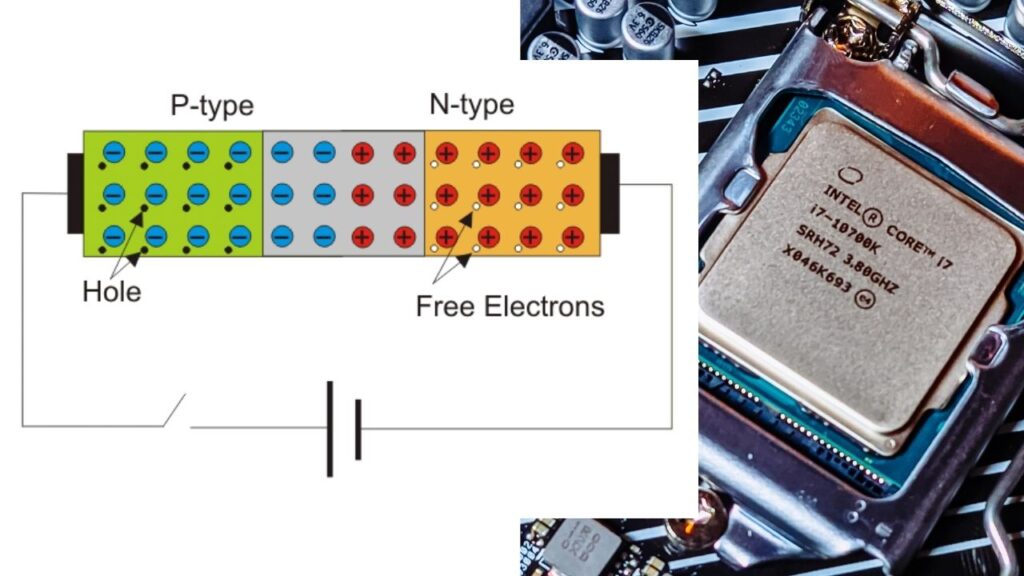

Semiconductors are the tiny “brains” inside almost every electronic device you use. They control how electricity flows, letting devices think, remember, and communicate. As technology advances, we need chips that are smaller, faster, and use less power. That’s why companies are always trying to shrink the size of these chips.

But making chips smaller is tricky. At sizes below 7 nanometers, even the tiniest mistake can ruin a whole batch. Yield—the number of good chips you get from each wafer—is crucial. If you can improve yield, you save money and make technology better for everyone.

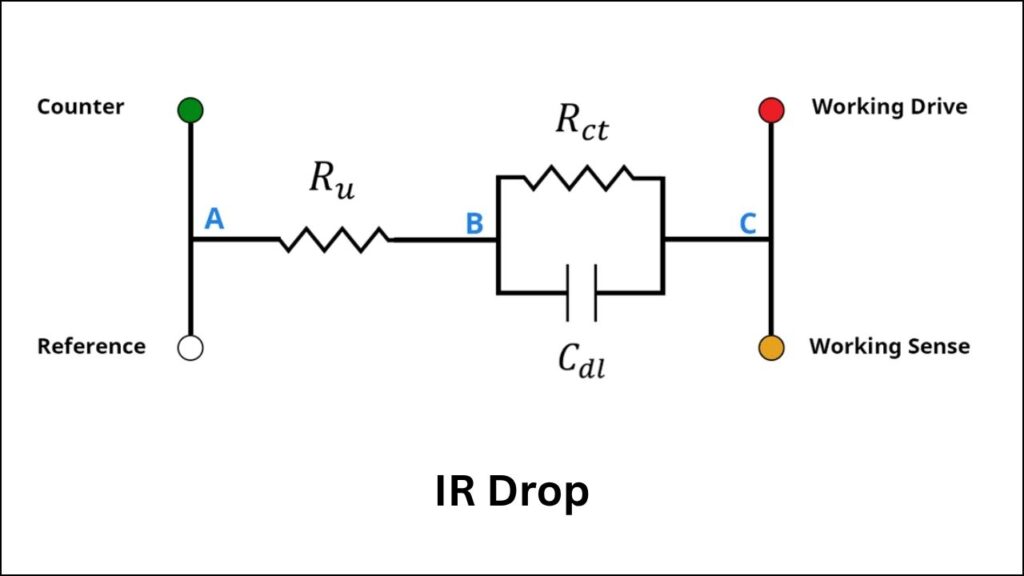

The Problem: IR Drop in Sub-7nm Chips

IR Drop is a fancy term for a simple idea: when electricity travels through a chip, it loses some of its power along the way. In tiny chips, this loss can cause some parts of the chip to not get enough electricity, so they don’t work right. This is a big problem at sub-7nm sizes, where everything is packed tightly together.

Traditional computers struggle to model and fix IR Drop at these tiny scales because the math gets too complicated. That’s where quantum computing comes in.

How Quantum Computing Helps

Quantum computers are a new kind of computer that can solve certain problems much faster than regular computers. They use the strange rules of quantum physics, which are very different from the rules we’re used to. Quantum computers are especially good at solving complex math problems, like the ones that describe how electricity moves through a chip.

SEALSQ, ColibriTD, and Xdigit are using quantum computing to model IR Drop with incredible accuracy.

This lets them predict and fix problems before they happen, so more chips come out perfect. Their solution uses advanced mathematical modeling and quantum algorithms to solve the equations that describe power distribution in chips.

The Partnership: Who’s Who

- SEALSQ: A company that makes secure chips and software for things like banking, cars, and the Internet of Things (IoT).

- ColibriTD: Experts in Quantum-as-a-Service (QaaS), which means they let other companies use quantum computers for their own projects.

- Xdigit: Specialists in chip design and math that helps predict and fix problems like IR Drop.

Together, these companies are working in the SEALSQ Quantum Lab to build a new system that can help chip makers get more good chips from each wafer.

What Does This Mean for Chip Makers and Everyone Else?

If you make chips, this is huge news. Boosting yield from 50% to 80% means you can make almost twice as many good chips from the same materials. That can cut the cost per chip by nearly half, saving millions of dollars for big factories.

For everyone else, it means better and cheaper technology. Chips are in everything, so if they’re cheaper and more reliable, your phone, car, and smart home gadgets get better too.

A Step-by-Step Guide: How the Solution Works

Let’s break down how this new solution works, step by step:

- Identify the Problem:

Chip makers notice that at sub-7nm sizes, too many chips fail because of IR Drop. - Model the Problem:

Xdigit uses advanced math to model how electricity moves through the chip and where power is lost. - Use Quantum Computing:

ColibriTD’s quantum computers solve the super-complex equations that describe IR Drop, finding solutions much faster than regular computers. - Predict and Fix:

The results help chip designers change their designs to prevent IR Drop before the chips are made. - Test and Improve:

The process is repeated, making each new batch of chips better than the last. - Deploy the Solution:

After a six-month proof-of-concept, the system will be ready for commercial use in 2026.

Real-World Examples and Practical Advice

Imagine you’re building a city in a video game. If you don’t plan where the roads go, traffic jams happen and people can’t get to work. Chip design is like that: if you don’t plan the “roads” (power lines) carefully, parts of the chip get “stuck in traffic” and don’t work.

Practical Tip:

If you work in chip design, try to learn about quantum computing and advanced math. These skills are becoming more important as chips get smaller.

For Kids:

Think of a chip as a tiny city. The electricity is like cars driving around. If the roads are too narrow or too long, some cars can’t get where they need to go. The new solution is like having a super-smart traffic planner who can fix all the roads before the city is built.

Data, Facts, and Statistics

- Current Yield at Sub-7nm: About 50% of chips on a wafer are good.

- Projected Yield with New Solution: Up to 80%.

- Cost Savings: Cutting per-chip costs by nearly half.

- Timeline: Six-month roadmap for proof-of-concept; commercial deployment in 2026.

- Applications: AI, automotive, IoT, and quantum-safe microcontrollers.

Quantum Breakthrough: Quantinuum Reaches Critical Milestone in Error Correction

How the Universe’s Basic Building Blocks Exploded Into Existence, According to a Physicist

Time May Not Be What We Think—Quantum-Scale Study Challenges Fundamental Physics

FAQs About SEALSQ Teams Up With Colibritd and Xdigit to Boost Semiconductor Yields

Q: What is IR Drop?

A: IR Drop is the loss of voltage (power) as electricity travels through the tiny wires inside a chip. It can cause parts of the chip to not work properly.

Q: Why is this a problem at sub-7nm sizes?

A: At these tiny sizes, the wires are so small and close together that even a little power loss can cause big problems.

Q: How does quantum computing help?

A: Quantum computers can solve the complex math problems that describe IR Drop much faster than regular computers, helping chip designers fix problems before they happen.

Q: When will this solution be available?

A: The partners are working on a six-month proof-of-concept, with commercial deployment expected in 2026.

Q: Who will benefit from this?

A: Chip makers, tech companies, and anyone who uses electronic devices—which is almost everyone!