The world of electronics is changing fast, and one of the most exciting advances is the development of a breakthrough eco-friendly plastic that could soon power the future of flexible electronics. This innovation, created by scientists at Case Western Reserve University, holds the promise of transforming everything from wearable health monitors to smart clothing—while also tackling the urgent problem of plastic pollution.

In this article, we’ll explore what makes this new plastic so special, how it works, why it’s safer for the environment, and what it could mean for the future of technology and sustainability. Whether you’re a curious student, a tech enthusiast, or a professional in the electronics industry, you’ll find practical insights and clear explanations to help you understand this game-changing discovery.

Breakthrough Eco-Friendly Plastic

| Feature / Fact | Details & Insights |

|---|---|

| Breakthrough Material | Fluorine-free ferroelectric polymer developed by Case Western Reserve University |

| Environmental Impact | No fluorine (avoids “forever chemical” pollution); safer for ecosystems and human health |

| Unique Properties | Flexible, does not require crystallization for electric properties, enabling soft, wearable electronics |

| Potential Applications | Wearable sensors, medical devices, AR/VR goggles, flexible displays, energy-efficient electronics |

| Scientific Recognition | Published in Science journal; patent pending |

| Current Limitations | Researchers are improving electrical and elastic properties for broader adoption |

| Professional Opportunities | Polymer science, green chemistry, electronics engineering, sustainability research |

| Official Resource | Case Western Reserve University |

The development of a breakthrough eco-friendly plastic by Case Western Reserve University marks a turning point for the electronics industry and environmental sustainability. By eliminating harmful “forever chemicals” and enabling flexible, high-performance devices, this innovation could power the future of wearable technology and beyond.

Whether you’re a student, professional, or simply a tech enthusiast, this is a story to watch. The journey from lab to market is underway, and the promise of a cleaner, smarter world is within reach.

What Is the Breakthrough Eco-Friendly Plastic?

The new material at the heart of this breakthrough is a ferroelectric polymer—a type of plastic that can generate and switch electric fields, making it perfect for use in electronic devices. What sets this polymer apart is its eco-friendly design. Unlike traditional ferroelectric plastics, which often contain fluorine (a chemical that never breaks down and pollutes the environment), this new polymer is fluorine-free.

Why Is Fluorine a Problem?

Fluorine-based plastics are known as “forever chemicals” because they persist in nature for centuries, accumulating in water, soil, and even our bodies. These chemicals are linked to health risks and are notoriously difficult to remove from the environment. By eliminating fluorine, the new plastic offers a safer, greener alternative.

How Does This Plastic Work?

To understand why this breakthrough matters, let’s break down some key concepts:

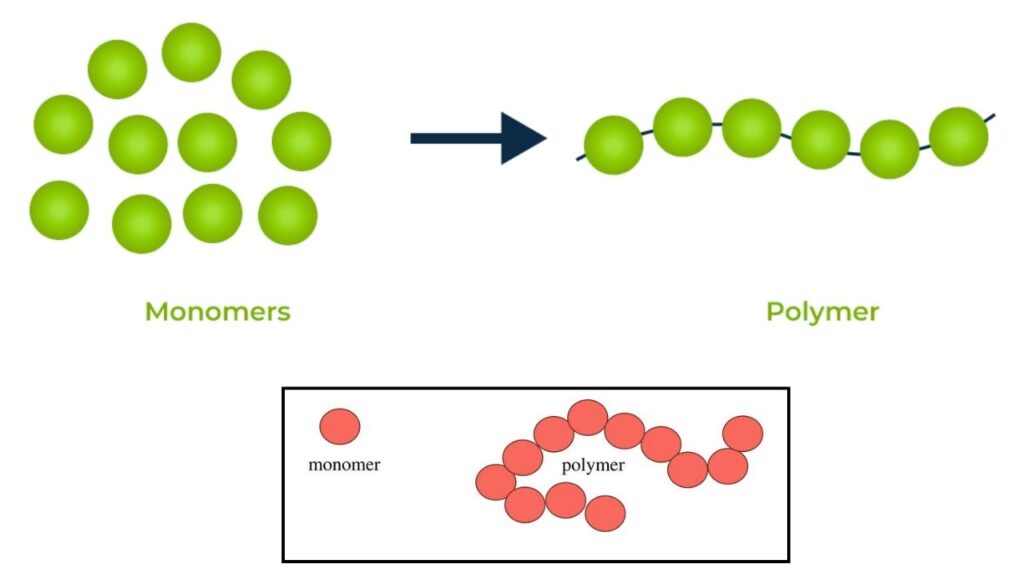

What Are Polymers?

Polymers are long chains of repeating molecules. Think of them like a string of beads, where each bead is a small molecule. Plastics are a type of polymer that can be engineered to be strong, flexible, or heat-resistant.

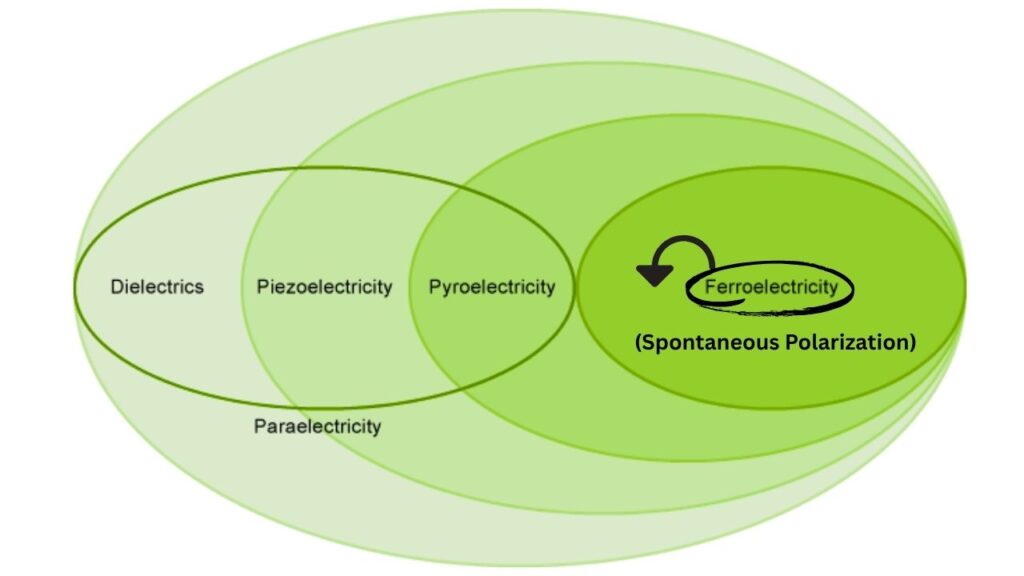

What Is Ferroelectricity?

Ferroelectric materials have a special property called spontaneous polarization. This means they can switch their electric charge direction when an electric field is applied—like flipping a light switch on and off. This property is crucial for making smaller, more efficient electronic devices.

What’s Different About the New Polymer?

Traditional ferroelectric polymers need to crystallize—become hard and rigid—to maintain their electric properties. This makes them brittle and less suitable for flexible electronics. The new polymer, however, does not require crystallization. It can stay soft and elastic while still generating electric properties, making it ideal for wearable devices that need to bend and flex.

Why Is This Important for Flexible Electronics?

Flexible electronics are devices that can bend, stretch, or twist without breaking. These include:

- Wearable health monitors that track your heart rate or steps

- Flexible displays for smartphones and tablets

- Medical sensors that stick to your skin like a bandage

- Smart clothing that can sense temperature or movement

The new eco-friendly plastic can make these devices lighter, more comfortable, and more sustainable. It also opens up possibilities for smaller, more energy-efficient gadgets that are easier to recycle.

The Science Behind the Innovation

How Is the Polymer Made?

The new polymer is created through a carefully controlled chemical process that avoids the use of fluorine. Instead, the scientists use alternative building blocks that allow the material to retain its ferroelectric properties without the need for crystallization. This is a significant scientific achievement because it means the material can remain soft and flexible, even in demanding conditions.

What Makes Ferroelectricity Possible Without Crystallization?

Most traditional ferroelectric polymers, like PVDF (polyvinylidene fluoride), rely on a crystalline structure to align their electric dipoles (tiny positive and negative charges within the material). The new polymer achieves ferroelectricity through a different mechanism, allowing the dipoles to align even in a non-crystalline, or amorphous, state. This breakthrough opens the door to a wide range of new applications.

Performance and Testing

Early tests show that the new polymer can switch its electric polarization reliably and repeatedly. Its flexibility and elasticity remain intact even after many cycles of bending and stretching. While researchers are still working to optimize its electrical output for commercial use, the results so far are promising for both performance and durability.

Environmental Benefits: A Step Toward a Greener Future

The environmental impact of plastics is a global concern. Traditional plastics, especially those containing fluorine, can linger in the environment for hundreds of years. They pollute oceans, harm wildlife, and even enter our food chain.

How Does the New Plastic Help?

- No Fluorine: The absence of fluorine means the plastic will not create “forever chemical” pollution.

- Potential for Recycling: Polymers can be engineered for better recyclability, reducing waste.

- Lower Carbon Footprint: By enabling more efficient electronics, the material can help reduce energy consumption.

This innovation is part of a broader movement in science and engineering to create materials that are both high-performing and environmentally responsible.

Practical Advice: How Can Professionals and Companies Benefit?

For engineers, designers, and manufacturers, this breakthrough offers several practical advantages:

- Design Freedom: The flexibility of the new plastic allows for creative device shapes and applications.

- Sustainability Goals: Companies can meet environmental targets by adopting greener materials.

- Competitive Edge: Early adoption of eco-friendly plastics can set brands apart in the growing market for sustainable tech.

For Students and Career Seekers

If you’re interested in a career in polymer science, green chemistry, or electronics engineering, now is the perfect time to get involved. The demand for experts in sustainable materials is rising, and innovations like this are shaping the future of technology.

How Does This Compare to Existing Plastics?

Let’s look at a simple comparison:

| Feature | Traditional Ferroelectric Plastic (PVDF) | New Eco-Friendly Polymer |

|---|---|---|

| Contains Fluorine | Yes | No |

| Environmental Impact | High (forever chemical) | Low (eco-friendly) |

| Flexibility | Rigid when crystallized | Flexible and elastic |

| Electric Properties | Requires crystallization | Works without crystallization |

| Recyclability | Difficult | Potentially easier |

Real-World Applications: What Could Change?

Wearable Health Devices

Imagine a fitness tracker that feels like a second skin, moves with your body, and is made from materials that won’t harm the planet. The new polymer could make this a reality, offering both comfort and sustainability.

Medical Sensors

Medical sensors that stick to your skin and monitor vital signs need to be soft, flexible, and safe. Using eco-friendly plastics reduces the risk of chemical exposure and makes disposal safer for the environment.

Flexible Displays and Smart Textiles

From rollable smartphone screens to clothing that can sense your temperature or movement, the possibilities are vast. The new polymer’s flexibility and performance could drive innovation in these fields, making electronics more integrated into daily life.

Energy-Efficient Electronics

Ferroelectric materials are key for making memory devices, capacitors, and sensors more efficient. By using a greener polymer, manufacturers can reduce the overall environmental impact of producing and operating these devices.

The Road Ahead: Challenges and Opportunities

While the new eco-friendly plastic is a major step forward, there are still challenges to overcome:

- Scaling Up Production: Manufacturing the polymer at large scale while maintaining quality.

- Optimizing Properties: Further improving its electrical and mechanical performance.

- Integration: Ensuring compatibility with existing electronic manufacturing processes.

Despite these hurdles, the potential impact is enormous. As more companies and researchers focus on sustainable materials, the future of electronics looks brighter—and greener—than ever.

Scientists Use Magnetic Chains and Superconductors to Create a New Quantum Material

Physicists Catch Light in Imaginary Time: What This Means for Science and You

World’s First Silicon-Free Computer Built With 2D Materials—A Major Shift Begins at Penn State

FAQs About Breakthrough Eco-Friendly Plastic

Q: What are “forever chemicals” and why are they harmful?

A: “Forever chemicals” are substances like fluorine-based compounds that do not break down in the environment. They accumulate over time, polluting water, soil, and even entering the food chain, posing health risks to humans and animals.

Q: How soon will this new plastic be available in products?

A: The material is still being improved for its electrical and elastic properties. It has been published in Science and is patent pending, so commercial products may appear in the next few years.

Q: Can this plastic be recycled?

A: Polymers can be engineered for recyclability. The new plastic’s eco-friendly design makes it more suitable for recycling and upcycling than traditional fluorine-based plastics.

Q: What kinds of devices will use this plastic?

A: Potential uses include wearable health monitors, medical sensors, flexible displays, smart clothing, and energy-efficient electronics.

Q: Who developed this material?

A: The breakthrough was made by researchers at Case Western Reserve University, led by Professor Lei Zhu, a leading expert in macromolecular science and engineering.