Aptar introduces dual-active material science technology for pharma—a phrase that’s capturing the attention of pharmaceutical professionals, healthcare providers, and patients around the world. This new technology promises to revolutionize how medicines and medical devices are protected, stored, and delivered, ensuring greater safety and efficacy for everyone who relies on modern healthcare.

In this article, we’ll explore what this innovation means, why it matters, and how it works, using clear explanations, practical examples, and expert insights. Whether you’re a pharmaceutical scientist, a healthcare worker, or simply someone interested in how your medicines stay safe, you’ll find valuable and trustworthy information here.

Aptar Introduces Dual-Active Material Science Technology for Pharma

| Feature/Stat | Details |

|---|---|

| Technology | Dual-active material science (controls both moisture and oxygen) |

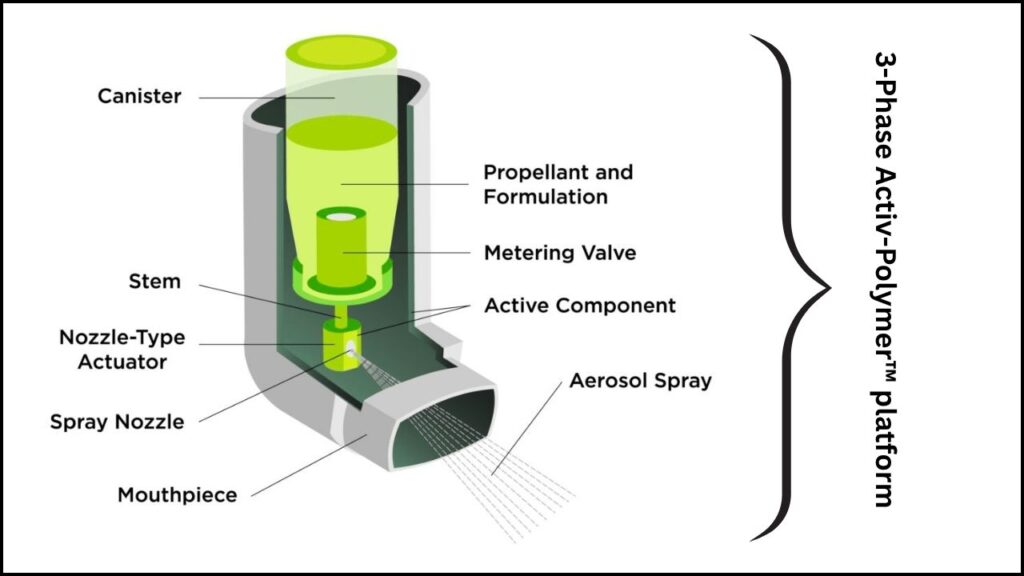

| Platform | Based on Aptar CSP Technologies’ patented 3-Phase Activ-Polymer™ platform |

| Applications | Oral solid dose drugs (e.g., GLP-1), implantable mesh devices, microarray patches, transdermal systems |

| Industry Impact | Extends shelf life, improves safety, reduces packaging complexity, accelerates speed-to-market |

| Regulatory Support | Helps meet ICH stability requirements and supports regulatory compliance |

| Official Website | Aptar CSP Technologies |

Aptar introduces dual-active material science technology for pharma, redefining how medicines and medical devices are protected from moisture and oxygen. This breakthrough extends shelf life, improves patient safety, simplifies packaging, and supports regulatory compliance. With its proven effectiveness and adaptability, dual-active technology is setting a new benchmark for pharmaceutical packaging worldwide.

Understanding Dual-Active Material Science Technology

What Is It?

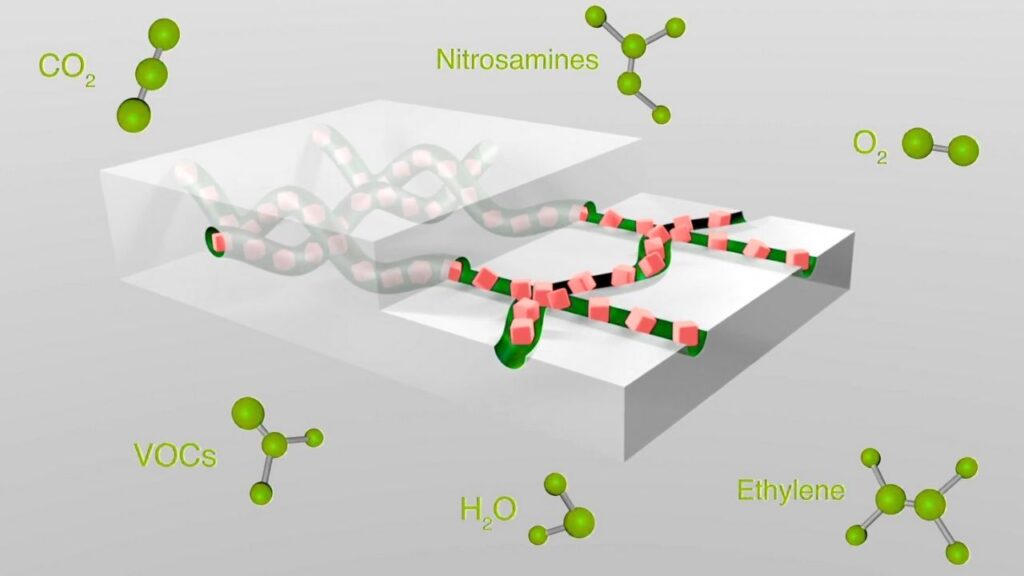

Dual-active material science technology is a new class of pharmaceutical packaging that can simultaneously control both moisture and oxygen inside a medicine container or medical device packaging. Traditionally, pharmaceutical companies have used separate solutions to tackle each problem: moisture-absorbing packets for humidity, and oxygen scavengers for air. Aptar’s innovation combines both functions into one integrated material, simplifying packaging and improving drug protection.

Why Are Moisture and Oxygen Such a Problem?

Medicines, especially advanced formulations like oral solid dose drugs, biologics, and implantable devices, are highly sensitive to their environment. Even small amounts of moisture or oxygen can cause:

- Chemical degradation: Active ingredients can break down, reducing drug potency.

- Physical changes: Pills may crumble, capsules may stick together, or powders may clump.

- Microbial growth: Moisture can allow bacteria or fungi to grow, making medicines unsafe.

- Color and odor changes: Oxidation can cause visible and sensory changes, signaling loss of quality.

For example, GLP-1 drugs used for diabetes and obesity management are particularly vulnerable to both moisture and oxygen. Without proper protection, their shelf life can be drastically shortened, and their effectiveness compromised.

How Does Aptar’s Technology Work?

The Science Behind the Solution

Aptar’s technology is based on its 3-Phase Activ-Polymer™ platform. This is not just a passive barrier; it’s an “active” material that interacts with the environment inside the package.

- Moisture Adsorption: The material contains special agents that attract and trap water vapor, keeping the inside of the package dry.

- Oxygen Scavenging: The same material also includes components that bind with and remove oxygen, preventing oxidation reactions.

Because both actions happen within the same material, there’s no need for separate packets or layers. This reduces the risk of human error (like forgetting to insert a desiccant) and makes the packaging process more efficient.

Real-World Example

Imagine a new oral medication for diabetes that is very sensitive to both water and air. With traditional packaging, manufacturers might use a moisture-absorbing packet and a separate oxygen scavenger, making the packaging bulky and increasing the chance of mistakes. With Aptar’s technology, a single integrated film or insert can do both jobs, ensuring consistent protection throughout the product’s shelf life.

Why Is This a Breakthrough for the Pharmaceutical Industry?

Meeting Regulatory Demands

Pharmaceutical products must meet strict global standards for stability and safety. The International Council for Harmonisation (ICH) sets guidelines for how stable a drug must be under various conditions. If a medicine degrades too quickly, it can’t be approved for sale. Aptar’s dual-active packaging helps companies meet these requirements more easily, supporting faster regulatory approval and safer products for patients.

Supporting Innovation in Drug Development

As new types of medicines are developed—such as biologics, personalized therapies, and advanced drug-device combinations—the need for more sophisticated packaging grows. Aptar’s technology can be customized for different products, from oral tablets to implantable devices, making it a versatile solution for modern pharmaceutical challenges.

Reducing Costs and Complexity

By combining moisture and oxygen control into one material, manufacturers can streamline their packaging processes, reduce material usage, and lower costs. Fewer packaging components also mean fewer opportunities for errors, which can lead to costly recalls or product failures.

Step-by-Step Guide: How Dual-Active Packaging Is Developed and Used

1. Assessment of Product Sensitivity

Pharmaceutical companies start by analyzing their product’s sensitivity to moisture and oxygen. This involves laboratory tests to determine how quickly the drug degrades under different environmental conditions.

2. Custom Solution Design

Based on this analysis, Aptar’s scientists design a packaging material using the 3-Phase Activ-Polymer™ platform. The material is engineered to provide the exact level of moisture and oxygen protection needed for that specific drug or device.

3. Integration into Packaging

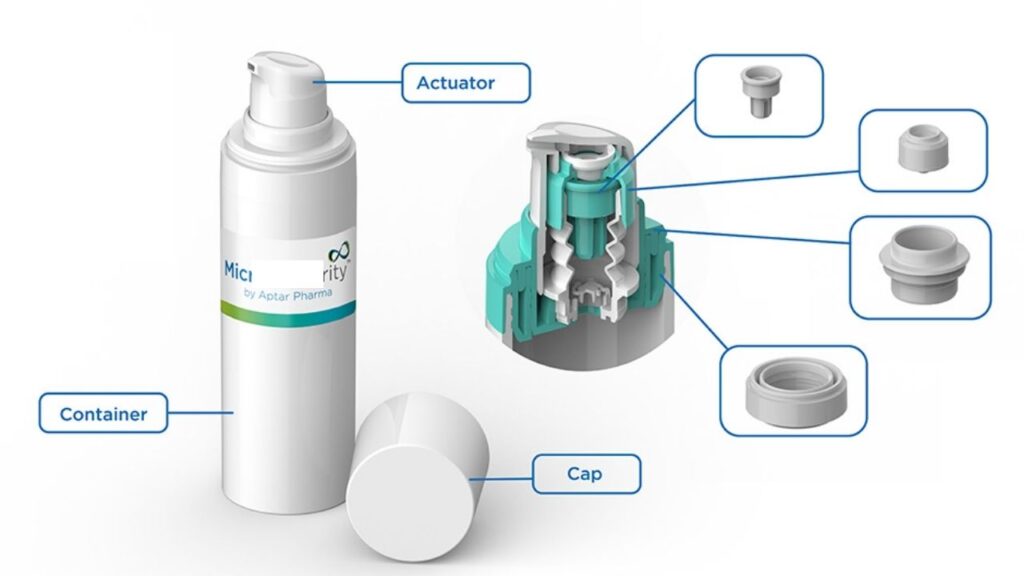

The dual-active material is formed into films, blisters, or inserts, which are then incorporated into the final packaging. This can happen during the manufacturing process, ensuring every package is protected from the start.

4. Stability Testing

Before the product is released, it undergoes rigorous stability testing. This means storing the packaged drug under various temperature and humidity conditions and measuring how well the active ingredients are preserved over time.

5. Regulatory Submission

The results of the stability tests are submitted to regulatory agencies as part of the drug approval process. Aptar’s technology helps companies demonstrate that their products remain safe and effective throughout their intended shelf life.

6. Commercial Launch and Ongoing Monitoring

Once approved, the product is launched with the new packaging. Companies may continue to monitor the product’s stability in the market, using data to further refine packaging solutions for future products.

Practical Advice for Pharma Professionals

Integrate Packaging Early in Development

Don’t wait until the end of the drug development process to think about packaging. Early integration of dual-active technology can prevent costly redesigns and speed up time to market.

Customize for Each Product

Every drug and device is different. Work with packaging experts to tailor the level of moisture and oxygen protection to your specific needs.

Educate Your Team

Make sure everyone involved in product development, from R&D to manufacturing to quality assurance, understands the benefits and requirements of dual-active packaging.

Plan for Global Distribution

If your product will be shipped to regions with high humidity or temperature swings, dual-active packaging can provide extra assurance that it will arrive in perfect condition.

Benefits for Patients, Healthcare Providers, and the Environment

For Patients

- Longer Shelf Life: Medicines stay effective for longer, reducing the risk of taking expired or degraded drugs.

- Greater Safety: Less chance of contamination or harmful breakdown products.

- Peace of Mind: Patients can trust that their medicines will work as intended, whether stored at home or in a clinic.

For Healthcare Providers

- Consistent Quality: Reliable medicines mean better treatment outcomes and fewer complications.

- Simplified Inventory: Longer shelf life reduces waste and makes inventory management easier.

For the Environment

- Less Waste: Fewer expired or recalled products mean less environmental impact.

- Reduced Packaging Materials: Integrated solutions require fewer components, supporting sustainability goals.

New Quantum State Discovery Set to Revolutionize Material Science Worldwide

AI Just Made 2D Materials Stronger—Here’s How It’s Changing the Future of Material Science

FAQs About Aptar Introduces Dual-Active Material Science Technology for Pharma

What is dual-active material science technology?

It’s a packaging innovation that actively controls both moisture and oxygen inside pharmaceutical and medical device packaging, protecting sensitive products from degradation.

Why are moisture and oxygen so important in drug packaging?

Both can cause medicines to break down, lose effectiveness, or become unsafe. Controlling these elements keeps drugs safer and more effective for longer.

Which medicines benefit most from this technology?

Sensitive oral solid dose drugs (like GLP-1 medications for diabetes and obesity), implantable devices, microarray patches, and transdermal delivery systems.

How does this help pharmaceutical companies?

It simplifies packaging, extends shelf life, reduces costs, and helps meet regulatory requirements, making it easier to bring new drugs to market.

Is this technology already in use?

Yes, dual-active material science technology is being adopted for new drug launches and medical devices, with proven results in extending product stability and safety.

The Future: Setting New Standards in Pharma Packaging

The pharmaceutical industry is under constant pressure to deliver safer, more effective medicines while reducing costs and environmental impact. Aptar’s dual-active material science technology is a significant leap forward in meeting these challenges. By offering a single, integrated solution for moisture and oxygen control, Aptar is helping companies bring better products to market, supporting healthcare professionals in delivering reliable care, and giving patients greater confidence in their treatments.

As drug formulations become more advanced and global distribution becomes more complex, the need for robust, adaptable packaging solutions will only grow. Dual-active technology is poised to become the new standard for protecting the next generation of medicines and medical devices.