A breakthrough eco-friendly camphor additive enhances the performance of perovskite solar cells—a phrase that’s capturing the imagination of scientists, solar industry professionals, and eco-conscious consumers alike. As the world races toward cleaner energy solutions, innovations that make solar technology more efficient, durable, and sustainable are more valuable than ever.

In this article, we’ll explore how a natural compound from the camphor tree is transforming the future of solar power. We’ll break down the science in simple terms, provide practical advice for different audiences, and offer a step-by-step guide to understanding this game-changing development. Whether you’re a curious student, a solar installer, or a researcher, you’ll find valuable, trustworthy insights here.

A Breakthrough Eco-Friendly Camphor Additive Enhances the Performance of Perovskite Solar Cells

| Feature/Stat | Details & Data |

|---|---|

| Additive Name | Camphorquinone (CQ), derived from the camphor tree |

| Efficiency Boost | 25.2% photoelectric conversion efficiency (PCE), up from 23.0% (a 9.6% improvement) |

| Lifespan | Retains >90% initial efficiency after 1,000 hours (doubles lifespan vs. standard cells) |

| Residue-Free Processing | CQ sublimates (goes from solid to gas) during manufacturing, leaving no residue |

| Eco-Friendly | Derived from natural sources, supports sustainable manufacturing |

| Professional Impact | Simplifies manufacturing, reduces costs, improves reliability and sustainability |

The discovery that a camphor-derived additive can dramatically enhance the performance of perovskite solar cells is a game-changer for the solar industry. With higher efficiency, doubled lifespan, and a sustainable, residue-free manufacturing process, this innovation brings us closer to a future where clean energy is both affordable and environmentally responsible. As solar technology continues to evolve, eco-friendly breakthroughs like this will play a crucial role in shaping the world’s energy landscape.

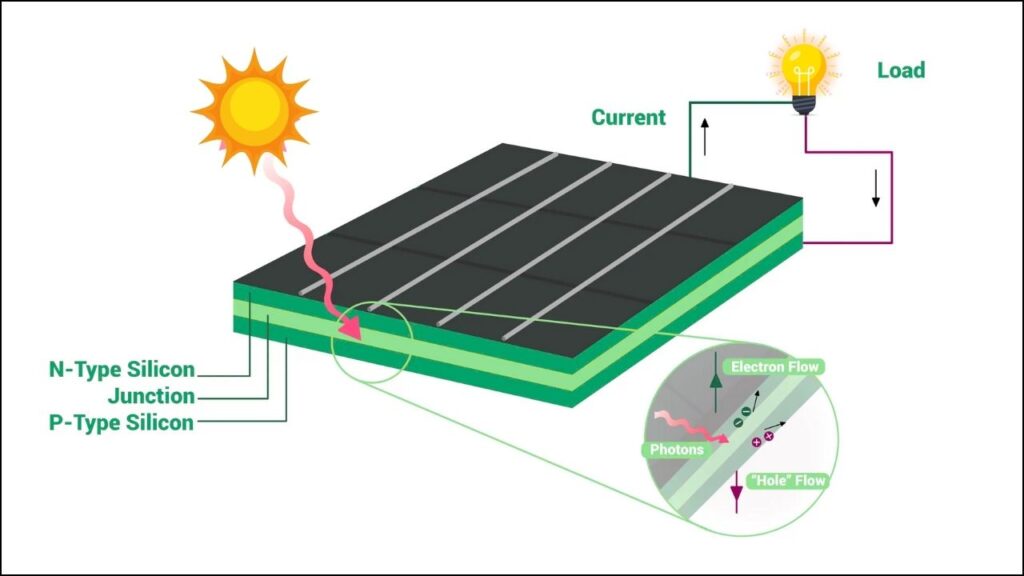

Understanding Perovskite Solar Cells: Why They Matter

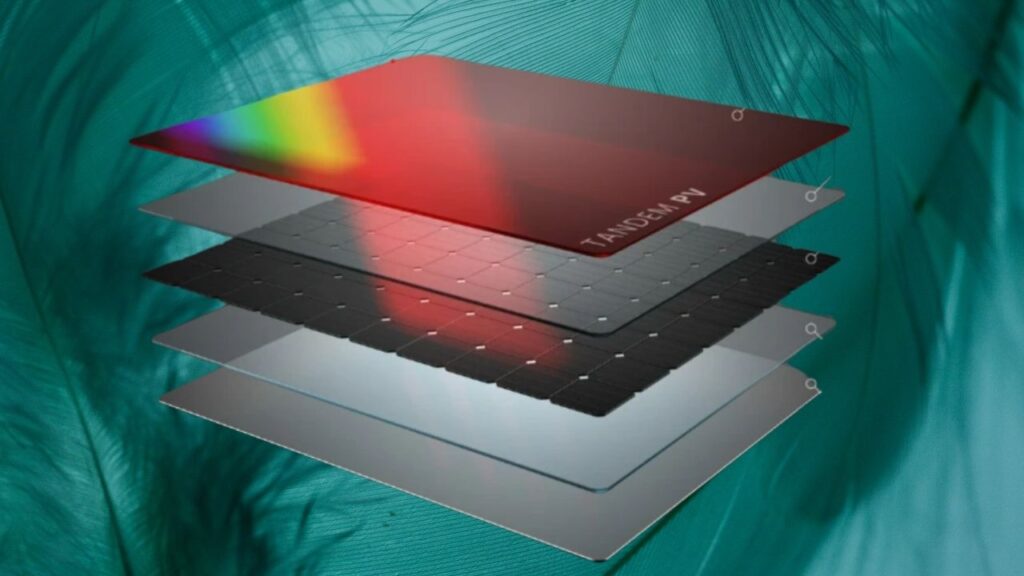

Perovskite solar cells represent one of the most promising advancements in renewable energy technology. Named for their unique crystal structure, these solar cells have quickly risen to prominence due to their impressive efficiency and versatility. Unlike traditional silicon-based solar panels, perovskite cells can be produced with less energy, at lower temperatures, and on flexible materials. This opens doors to lightweight, portable, and even semi-transparent solar panels that could be integrated into windows, vehicles, or wearable devices.

Despite these advantages, perovskite solar cells have historically faced two significant hurdles:

- Stability: They are prone to degradation from heat, moisture, and light, leading to shorter lifespans compared to silicon panels.

- Sustainability: Some manufacturing additives can be toxic or leave behind residues that harm both performance and the environment.

The introduction of a camphor-derived additive is a major leap forward in addressing both these challenges.

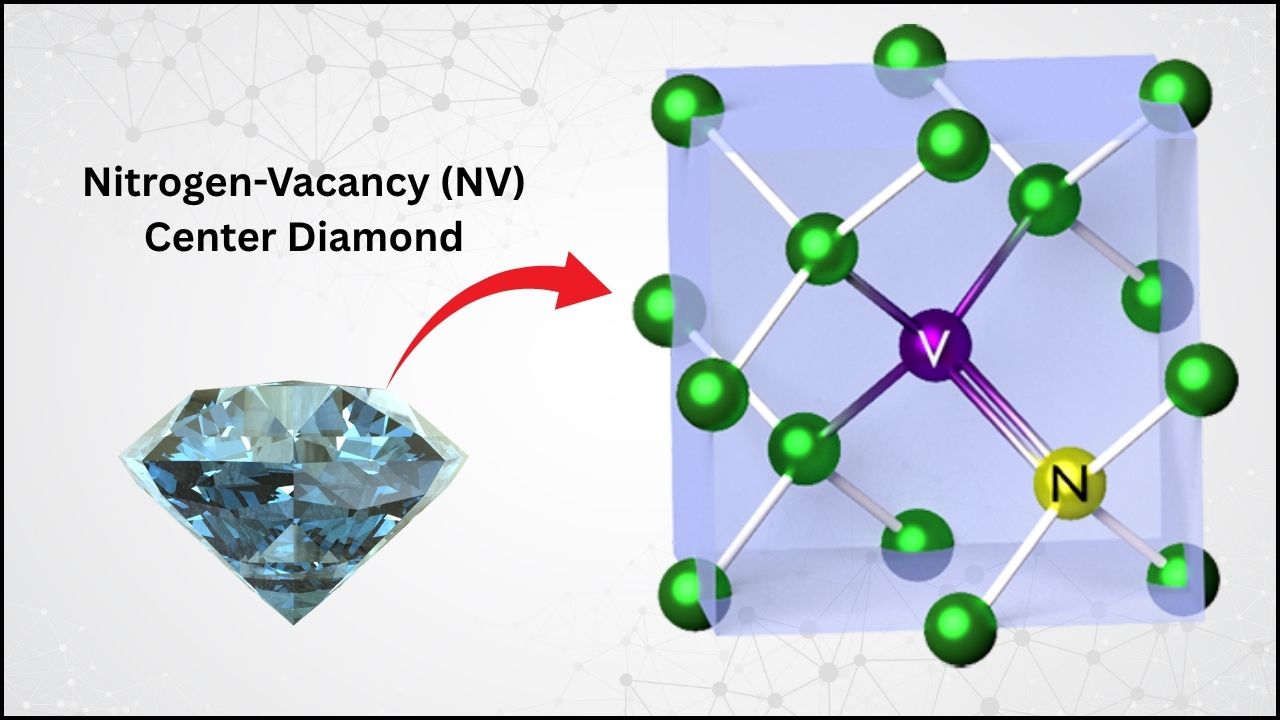

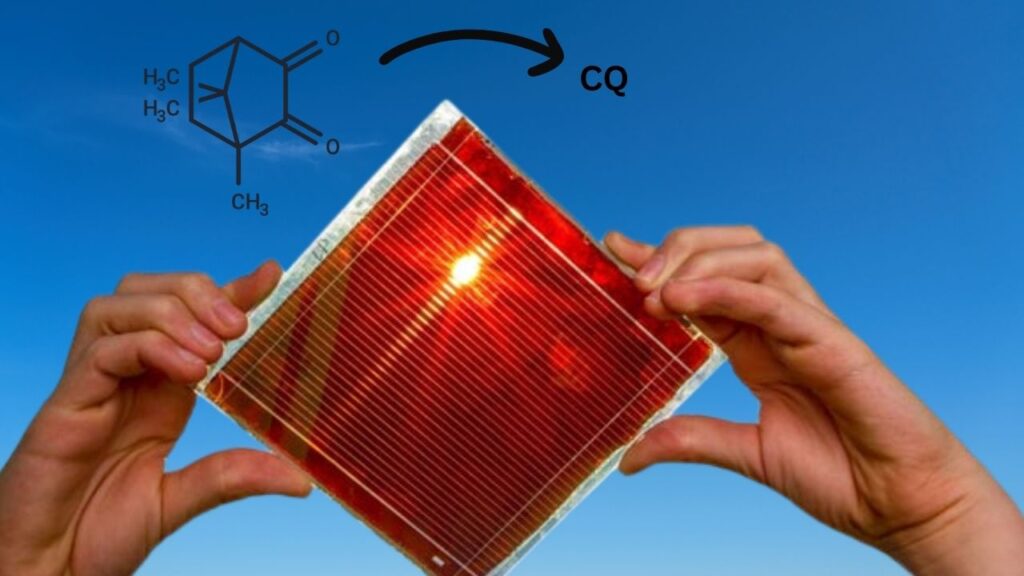

The Science Behind Camphorquinone: Making Complex Chemistry Simple

Camphorquinone (CQ) is a naturally occurring compound extracted from the camphor tree, a plant long valued for its aromatic wood and medicinal properties. In the context of solar technology, CQ serves as a temporary “helper” during the formation of the perovskite layer—the part of the solar cell that actually absorbs sunlight and converts it into electricity.

Here’s how CQ works its magic:

1. Stepwise Sublimation: The Two-Stage Process

- First Stage: When CQ is added to the perovskite precursor solution and heated, it helps form uniform “seed” crystals. These seeds act as the foundation for the perovskite layer, ensuring that the crystals grow evenly and with fewer defects.

- Second Stage: As the temperature increases, CQ sublimates—meaning it transitions directly from a solid to a gas. This gradual disappearance allows the crystal structure to finish forming without any leftover additive.

2. Residue-Free and Clean

Because CQ completely sublimates, it leaves no trace in the finished solar cell. This is a significant advantage over many traditional additives, which can linger and cause long-term issues.

3. Larger, More Uniform Crystals

The controlled growth facilitated by CQ results in bigger, more orderly perovskite crystals. This is important because defects or irregularities in the crystal structure can trap electrons, reducing the efficiency of the solar cell. Larger, well-formed crystals allow electricity to flow more freely, boosting overall performance.

Real-World Results: Data That Matters

Let’s examine the impact of this innovation in numbers and practical terms:

- Efficiency: Solar cells produced with CQ achieved a photoelectric conversion efficiency (PCE) of 25.2%, compared to 23.0% for those without the additive. This 9.6% relative improvement is substantial, especially in a field where even a 1% gain is considered noteworthy.

- Lifespan: Under continuous operation at maximum power output, these cells retained more than 90% of their initial efficiency after 1,000 hours. In contrast, many traditional perovskite cells experience significant drops in performance over the same period.

- Manufacturing Simplicity: The absence of residue means fewer cleaning steps, less risk of contamination, and potentially lower production costs.

These results are not just laboratory curiosities—they signal a real potential for commercial solar panels that are more reliable, longer-lasting, and environmentally friendly.

Why Is This Breakthrough Eco-Friendly?

The environmental benefits of using camphorquinone are significant:

- Natural Origin: CQ is derived from the camphor tree, a renewable resource. This contrasts with many synthetic additives, which may be petroleum-based or involve hazardous chemicals.

- No Toxic Byproducts: Because CQ sublimates completely, it doesn’t leave behind any waste that could pollute the environment or complicate recycling.

- Supports Circular Economy: Using bio-based, biodegradable materials aligns with broader sustainability goals, helping the solar industry reduce its environmental footprint.

This approach also supports the development of “green manufacturing” processes, which are increasingly important as solar energy adoption grows worldwide.

Step-by-Step: How Camphor Additive Improves Perovskite Solar Cells

Let’s break down the process in a way that’s easy to follow:

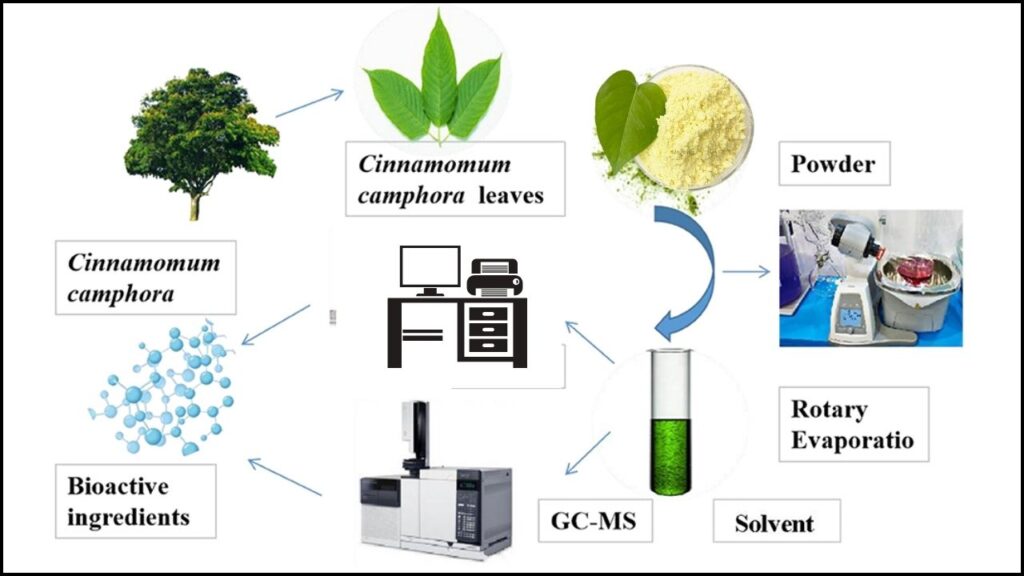

Step 1: Extraction and Preparation

- Camphor is harvested from camphor trees and processed to obtain camphorquinone.

- CQ is purified and prepared for use as an additive in solar cell manufacturing.

Step 2: Mixing with Perovskite Precursors

- CQ is added to the solution that will form the perovskite layer.

- This mixture is applied to a substrate (the base material for the solar cell).

Step 3: Controlled Heating

- The coated substrate is heated in a controlled environment.

- CQ helps organize the formation of perovskite crystals during the initial heating.

Step 4: Sublimation and Crystallization

- As the temperature increases, CQ sublimates, leaving the perovskite crystals to finish forming without any chemical residue.

- The result is a uniform, defect-free crystal layer.

Step 5: Device Assembly

- The perovskite layer is combined with other components (such as electrodes and protective coatings) to create the final solar cell.

Step 6: Testing and Quality Control

- The finished solar cells are tested for efficiency, stability, and durability before being integrated into solar panels.

Practical Advice: What This Means for Different Audiences

For Homeowners and Consumers

- Better Value: Future solar panels may offer higher efficiency and longer lifespans, meaning you’ll get more electricity and savings from your investment.

- Greener Choice: Panels made with eco-friendly additives are better for the environment, reducing your carbon footprint even further.

For Solar Installers and Businesses

- Easier Installation: Panels that are more reliable and longer-lasting reduce the need for maintenance and replacement.

- Competitive Advantage: Offering advanced, sustainable products can set your business apart in a crowded market.

For Researchers and Industry Professionals

- New Research Opportunities: The success of camphorquinone opens the door to exploring other natural, volatile additives for solar cell manufacturing.

- Scalability: The residue-free process simplifies manufacturing, making it easier to scale up production for commercial use.

Tin-Based Pb-Free Perovskite Solar Cells Hit 16.65% Efficiency With 1500-Hour Stability

Scientists Build 29.5 %‑Efficiency All‑Perovskite Tandem Solar Cells

Inside the Lab: Breakthroughs in Organic Solar Cells Could Change Energy Forever

FAQs About A Breakthrough Eco-Friendly Camphor Additive Enhances the Performance of Perovskite Solar Cells

What is camphorquinone and why is it important?

Camphorquinone is a compound derived from the camphor tree. It acts as a temporary additive during solar cell manufacturing, helping to form high-quality perovskite crystals and then sublimating away, leaving no residue.

How much does camphorquinone improve solar cell efficiency?

The use of camphorquinone has been shown to increase the efficiency of perovskite solar cells from 23.0% to 25.2%, a significant improvement in the field.

Does this technology make solar panels more expensive?

On the contrary, the simplified manufacturing process and reduced risk of defects can lower production costs, potentially making solar panels more affordable in the long run.

Is this technology available for commercial use?

As of mid-2025, the technology is in advanced research and pilot production stages. Commercial products incorporating camphorquinone are expected to become available as the process is scaled up.

Are there any environmental risks associated with camphorquinone?

No. Camphorquinone is eco-friendly, derived from renewable resources, and does not leave any toxic residues in the finished product.

The Future of Solar: What’s Next?

The introduction of eco-friendly camphor additives into perovskite solar cell manufacturing is a major milestone for the renewable energy sector. As researchers continue to refine the process and scale up production, we can expect to see even greater improvements in efficiency, durability, and sustainability.

This breakthrough also highlights the importance of looking to nature for solutions to modern technological challenges. By harnessing the unique properties of natural compounds, scientists are paving the way for a cleaner, greener energy future.