Imagine a world where cars, trucks, ships, and even airplanes run on fuel so clean, the only byproduct is water. That’s the promise of green hydrogen—a fuel made by splitting water using sunshine. A stunning new discovery from Sweden, a triple-layer catalyst, has pushed green hydrogen production to new heights, making this dream a lot more real.

Green hydrogen is hydrogen produced by splitting water using renewable electricity, such as solar or wind power. Unlike most hydrogen today—which comes from fossil fuels and releases harmful greenhouse gases—green hydrogen is truly clean. Right now, though, it’s expensive, and we only make a tiny fraction of the hydrogen we need this way. The new triple-layer catalyst might change everything. It uses sunlight and a special material “sandwich” to produce eight times more hydrogen than before. That could mean faster, cheaper, and greener hydrogen for all of us.

But why does this matter? Because green hydrogen could power heavy trucks, ships, and planes that can’t run on batteries—the kinds of vehicles we’ll still need even after the world shifts to electric cars. It could help factories make steel, chemicals, and fertilizers without polluting the planet. And, for communities far from the power grid, it could provide a way to store renewable energy for days when the sun isn’t shining or the wind isn’t blowing.

Let’s dive into how this breakthrough works, what it means for you, and what comes next.

New Triple-Layer Catalyst Boosts Green Hydrogen Output by 800%

| Aspect | Detail | What It Means for You |

|---|---|---|

| Hydrogen Market Growth | Green hydrogen market projected to reach $70 billion by 2035, up from $1.5 billion in 2024. | Huge job and investment opportunities in clean energy as costs fall and technology improves. |

| Catalyst Efficiency | New triple-layer material produces eight times more hydrogen than previous methods (800% increase). | Clean hydrogen could become affordable for heavy transport, industry, and energy storage—faster than expected. |

| Hydrogen’s Energy Density | Hydrogen contains 120 megajoules per kilogram—almost three times more than gasoline (45 MJ/kg). | Ideal for big vehicles and industries that need lots of energy in a small space. |

| Global Hydrogen Demand | Expected to rise to 125 million tons by 2030, over 500 million by 2050. | Demand for new technologies and skills will surge as hydrogen replaces fossil fuels in hard-to-decarbonize sectors. |

| Leading Producers | China: 61% of global green hydrogen capacity. | China leads, but North America and Europe are catching up with strong policies and investments. |

| Current Cost Challenges | Green hydrogen: $4–$12 per kilogram (gray: $1–$3/kg). | Prices must fall further for green hydrogen to compete, but breakthroughs like the triple-layer catalyst help. |

| Government Support | 60+ national hydrogen strategies; US Inflation Reduction Act (IRA), EU targets. | Strong policy push worldwide—look for news on hydrogen funding and new jobs in your country. |

| Career Opportunities | Engineers, scientists, policy experts, technicians in hydrogen and renewables. | Green jobs are booming—startups and big companies need talent to build the hydrogen economy. |

| Biggest Contracts | RWE to supply 30,000 tons/year green hydrogen to TotalEnergies in Germany. | Major companies are switching to hydrogen; more big deals coming as tech gets cheaper. |

The triple-layer catalyst is a major leap forward for green hydrogen and clean energy. By making water-splitting eight times more efficient, this technology could unlock the potential of hydrogen as a truly green fuel for transport, industry, and energy storage. While challenges remain—cost, infrastructure, and policy—the world is now much closer to a future where clean, affordable hydrogen powers our most important sectors.

For professionals, this means new jobs, new investments, and a chance to help shape the energy transition. For kids and families, it means hope for a cleaner planet. For everyone, it’s a reminder that science and innovation can solve even the toughest challenges, one breakthrough at a time.

How Does Green Hydrogen Work—And Why Is It So Important?

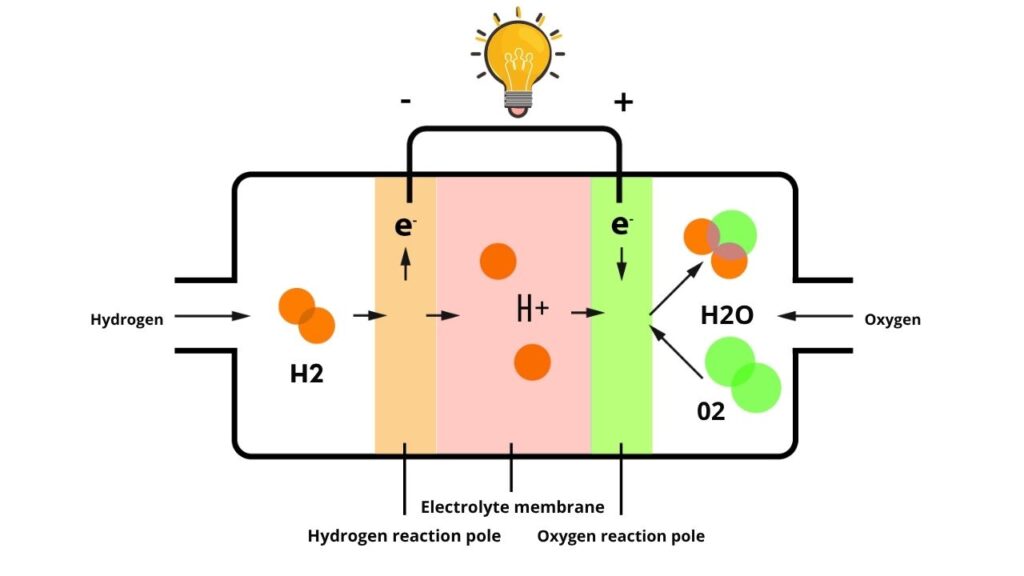

Most hydrogen today isn’t green. It’s called gray hydrogen and comes from natural gas, releasing up to 10 tons of carbon dioxide for every ton of hydrogen made. That’s a big contributor to climate change. Green hydrogen is different—it uses renewable electricity to split water (H₂O) into hydrogen (H₂) and oxygen (O₂). The only byproduct is water, so it’s truly zero-emission.

Hydrogen is special because it’s the lightest and most energy-packed element. It carries almost three times more energy per kilogram than gasoline. It can be stored, transported, and turned back into electricity when needed—perfect for heavy-duty vehicles, big factories, or places far from the grid.

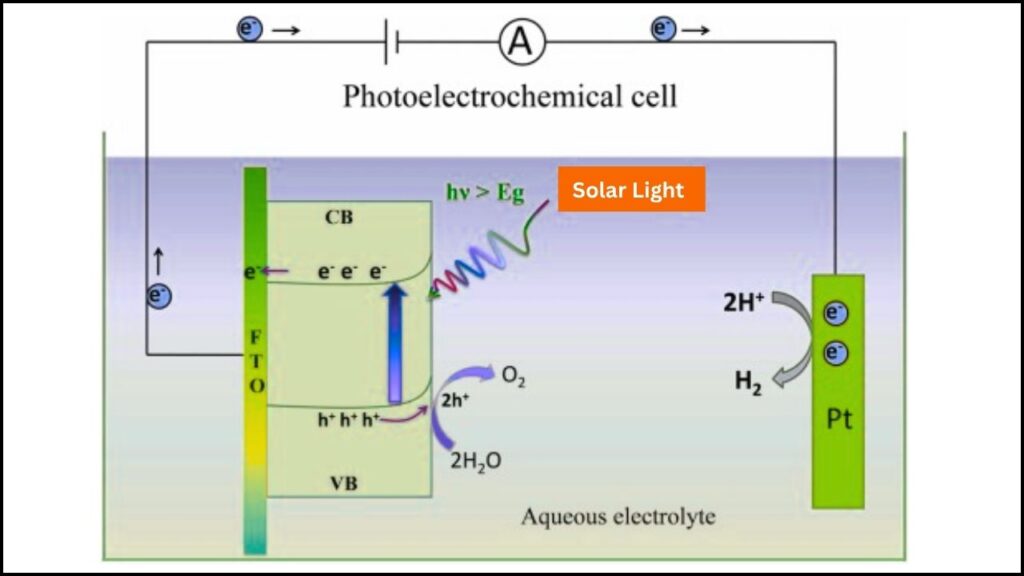

But until now, making green hydrogen has been expensive and slow. The technology to split water using sunlight (called “photochemical water splitting”) has been stuck at just 1–3% efficiency—far below the 10% target needed to make it practical for everyday use. The main problem has been that when sunlight hits a material, it creates positive and negative charges that quickly recombine, wasting most of the energy.

The Triple-Layer Catalyst Breakthrough: How It Works

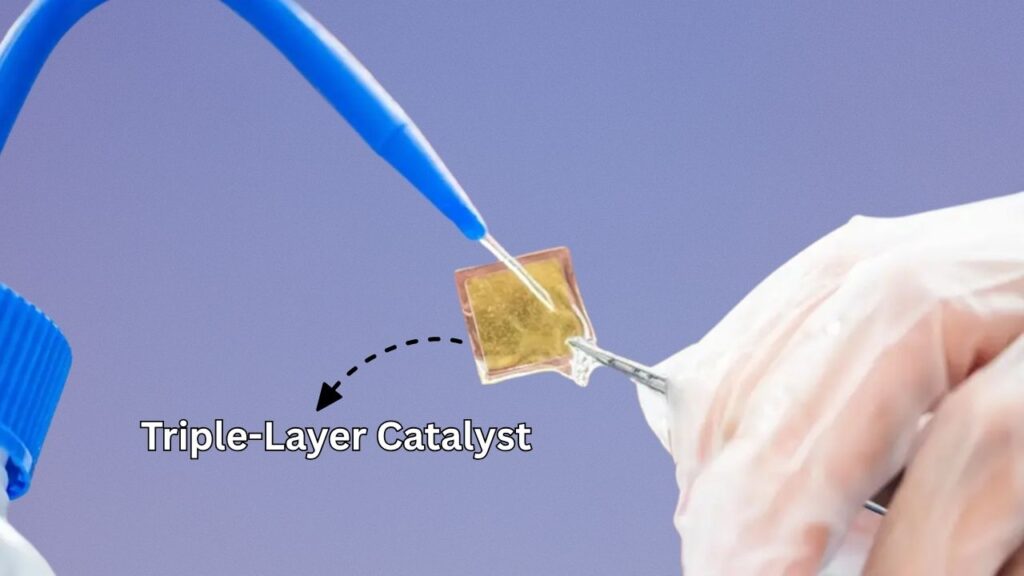

Scientists at Linköping University in Sweden have invented a triple-layer catalyst that tackles this problem head-on. Here’s how it works in simple terms:

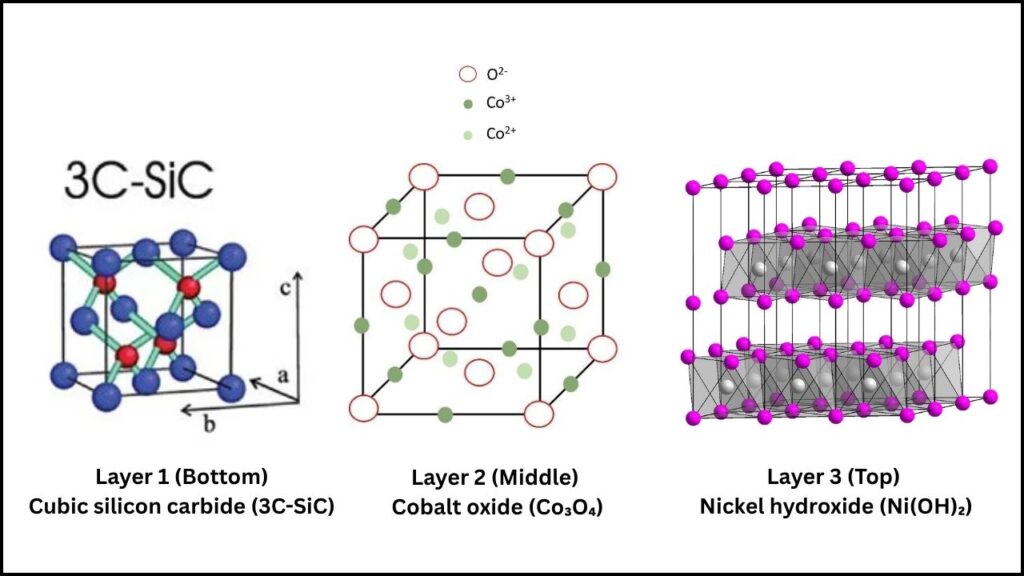

- Layer 1 (Bottom): Cubic silicon carbide (3C-SiC)—This layer absorbs sunlight to start the reaction.

- Layer 2 (Middle): Cobalt oxide (Co₃O₄)—It protects Layer 1 and helps the electric current flow.

- Layer 3 (Top): Nickel hydroxide (Ni(OH)₂)—This is the “worker” layer. It speeds up the water-splitting reaction.

Think of the catalyst as a high-tech club sandwich, where each slice does a special job. When sunlight hits the sandwich (catalyst), it creates electric charges. Instead of wasting energy, the three layers work together to separate these charges—keeping them from canceling each other out. The result: The new material splits water into hydrogen eight times faster than old methods.

That’s an 800% increase in green hydrogen production, just by changing the material structure.

Why Is This Such a Big Deal?

For years, researchers have struggled to make green hydrogen affordable and practical. Most systems are still too expensive or too slow. But with this new triple-layer catalyst, the same amount of sunlight can now make much more hydrogen. That means:

- Heavy-duty vehicles—Like trucks, ships, and planes—could run on green hydrogen, even though they can’t use batteries.

- Factories—Could switch from fossil fuels to green hydrogen, slashing pollution and operating costs.

- Energy storage—Communities could use hydrogen to store solar and wind power for later use, making renewables reliable 24/7.

Professor Jianwu Sun, who led the research, explains: “Passenger cars can have a battery, but heavy trucks, ships or aircraft cannot use a battery to store the energy. For these means of transport, we need to find clean and renewable energy sources, and hydrogen is a good candidate.”

Challenges and Opportunities Ahead

Green hydrogen is not a silver bullet. There are still a few big hurdles to clear:

- Cost: Green hydrogen is still more expensive than hydrogen from fossil fuels. But prices are dropping fast, and breakthroughs like the triple-layer catalyst will help.

- Infrastructure: We need new pipelines, storage tanks, and fueling stations for hydrogen, just like we have for gasoline.

- Energy Efficiency: Turning electricity into hydrogen, and back into electricity, loses some energy along the way. Making the whole process more efficient is a major focus for scientists.

- Policy: Governments need to invest in hydrogen research, build infrastructure, and set clear rules to speed up adoption.

But the opportunities are even bigger:

- Jobs: The hydrogen industry will need engineers, scientists, builders, policy experts, and technicians—lots of exciting new careers.

- Innovation: Startups and big companies are racing to invent better catalysts, cheaper electrolyzers, and smarter ways to use hydrogen.

- Climate Impact: Green hydrogen could cut billions of tons of CO₂ emissions every year, helping fight climate change and clean up our air.

How Does This Compare to Other Clean Energy Options?

Hydrogen isn’t the only clean energy solution. Batteries, wind, solar, and hydropower are all important. But hydrogen has some unique strengths:

- High Energy Density: Hydrogen packs more energy per kilogram than batteries or gasoline—ideal for big vehicles and industrial uses.

- Versatility: You can use hydrogen as fuel, for chemical reactions, or for storing renewable energy—jobs that batteries can’t do yet.

- Clean Byproduct: Burning hydrogen only produces water—no smog, no greenhouse gases.

But hydrogen isn’t perfect:

Making green hydrogen takes a lot of electricity. Storing and transporting hydrogen needs careful handling. And, despite big improvements, it’s still more expensive than fossil fuels in most places. That’s why breakthroughs like the triple-layer catalyst are so important—they help solve these problems step by step.

A Glimpse Into the Future

The team at Linköping University is working toward a long-term goal: using only sunlight to power the reaction, without needing extra electricity. Today, most green hydrogen is made using renewable electricity (not just sunlight), which adds cost. If scientists can get photochemical water splitting to 10% efficiency, green hydrogen could become much cheaper and more widely used. The researchers estimate it might take 5–10 more years to reach this milestone.

In the meantime, big companies are already betting on green hydrogen. In Germany, RWE has signed a deal to supply 30,000 tons of green hydrogen per year to TotalEnergies—a sign that the hydrogen economy is picking up speed.

Hydrogen Fuel at Half the Cost? New Catalyst from South Korea

Breakthrough Electrodes Could Make Green Hydrogen Cheaper and Last Longer Than Ever

FAQs About New Triple-Layer Catalyst Boosts Green Hydrogen Output by 800%

What is green hydrogen?

Green hydrogen is hydrogen gas made by splitting water using renewable electricity, like solar or wind power. The only byproduct is water, so it’s truly clean and zero-emission.

Why is green hydrogen important?

Hydrogen can store energy, power vehicles, and replace fossil fuels in industries like steel, chemicals, and shipping—shrinking our carbon footprint and helping fight climate change.

How does the new triple-layer catalyst work?

The triple-layer catalyst uses three specially designed layers (3C-SiC, Co₃O₄, Ni(OH)₂) to split water much more efficiently when sunlight hits. The layers work together to keep electric charges from canceling each other out, boosting hydrogen production by 800%.

How much does green hydrogen cost?

Green hydrogen costs about $4–$12 per kilogram today, but prices are falling as technology improves. The U.S. Department of Energy hopes to get to $1 per kilogram by 2030.

Where is green hydrogen used now?

Green hydrogen is starting to be used in industry—especially in Europe and Asia—for refining oil, making chemicals and fertilizers, and in some vehicles. As costs fall, more uses are expected.

What are the biggest challenges for green hydrogen?

High costs, limited infrastructure, and energy losses are the main hurdles today. But new technologies, government support, and investment are helping to overcome them.

How can I get involved in green hydrogen?

Careers in engineering, science, policy, and business related to energy and the environment are growing fast thanks to green hydrogen. Learning about chemistry, renewable energy, and sustainability is a great first step.