The surge in electronic waste, or e-waste, is a growing concern worldwide, posing environmental challenges and resource shortages. In response, AI-powered robots that can take apart smartphones piece by piece are revolutionizing the way we recycle electronics. These intelligent robots are transforming a traditionally laborious, inefficient process into a smarter, faster, and highly precise operation. This article explores how AI-driven robotic disassembly works, why it matters, and what it means for the future of recycling and sustainability.

Table of Contents

Why Disassembling Smartphones Matters

Every year, millions of smartphones become obsolete or discarded, creating mountains of e-waste packed with valuable materials such as gold, silver, copper, and rare earth elements. According to recent reports, the volume of e-waste is projected to reach about 74 million metric tons by 2030 globally, yet only a tiny fraction of this waste is properly recycled. The rest often ends up in landfills or incinerators, causing pollution and wasting precious resources.

Traditionally, e-waste recycling methods involve shredding devices into pieces, which can mix materials and reduce their value or usefulness. Manual disassembly of phones to recover specific parts or materials is costly, slow, and not scalable.

AI-powered robots offer a solution by automatically taking apart devices piece by piece, ensuring valuable components can be recovered efficiently and safely, minimizing waste, and reducing environmental impact. This opens the door to creating a true circular economy where materials are continuously reused instead of discarded.

AI-Powered Robots Can Now Take Apart Your Smartphone Piece By Piece

| Aspect | Details |

|---|---|

| Global e-waste by 2030 | Estimated 74 million metric tons |

| AI Robot Disassembly Speed | Apple’s Daisy robot disassembles up to 200 phones per hour |

| Technologies Used | AI, machine learning, computer vision, robotics, 3D scanning |

| Benefits | Reduces e-waste, improves material recovery, lowers environmental pollution, supports circular economy |

| Leading Innovators | Apple, Carnegie Mellon University, Fraunhofer Institute |

| Example Projects | Apple’s Daisy, CMU’s roboLoop robot, Fraunhofer’s iDEAR project |

| Official Resource | United Nations E-Waste Report |

The rise of AI-powered robots capable of taking apart smartphones piece by piece is a game changer for e-waste recycling and the broader sustainability movement. These robots offer a smarter, safer, and more efficient way to recover valuable materials while minimizing environmental harm. From Apple’s Daisy to innovative research labs, AI and robotics are paving the way for a circular economy where electronic waste is truly transformed into raw materials for new products.

As technology advances, we can expect these intelligent systems to become essential players in tackling the global e-waste crisis—delivering environmental benefits, economic advantages, and exciting career opportunities in robotics and green tech. Whether you are a professional in manufacturing, recycling, or conservation, understanding and embracing this technology is key to a sustainable future.

How AI-Powered Robots Disassemble Smartphones

1. Identification and Analysis

Before disassembly begins, the robot performs a detailed scan of the device. Using high-resolution cameras, 3D imaging, and sensors, AI algorithms identify the phone model, components, screws, and connections. This enables the robot to adapt to many different phone types and designs rather than relying on a fixed process.

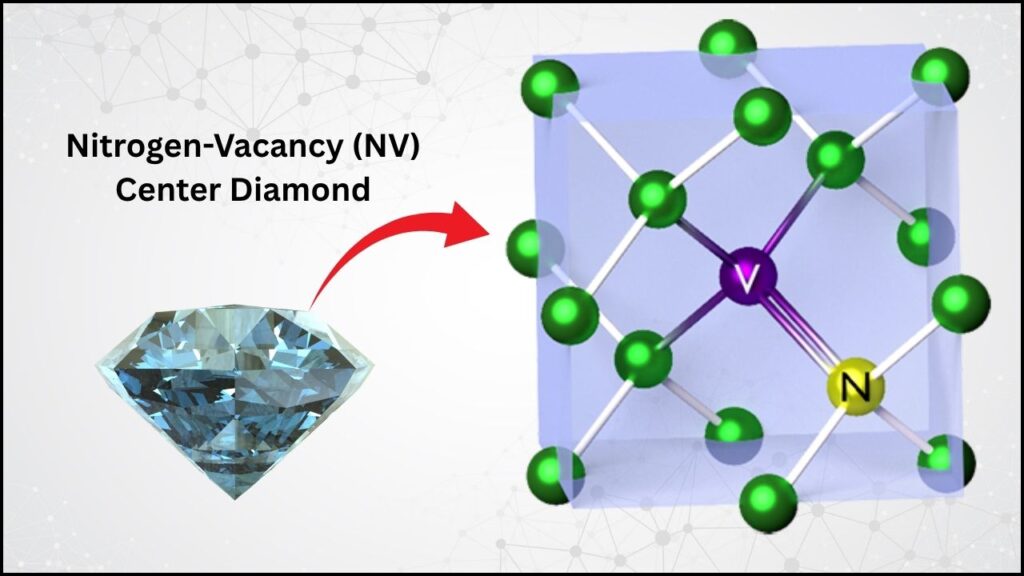

For example, Carnegie Mellon University’s researchers use AI that fuses real and X-ray images of phones to classify objects inside accurately. These technologies enable the robot to understand the exact structure and condition of each phone coming through the recycling line.

2. Generating the Disassembly Plan

Once the phone is analyzed, AI software creates a custom disassembly sequence tailored to that specific device. The software decides whether to fully disassemble it or selectively remove valuable parts like batteries, cameras, or circuit boards.

The plan includes detailed robot instructions for every step — such as unscrewing bolts, lifting components, cutting wires, or bending parts carefully.

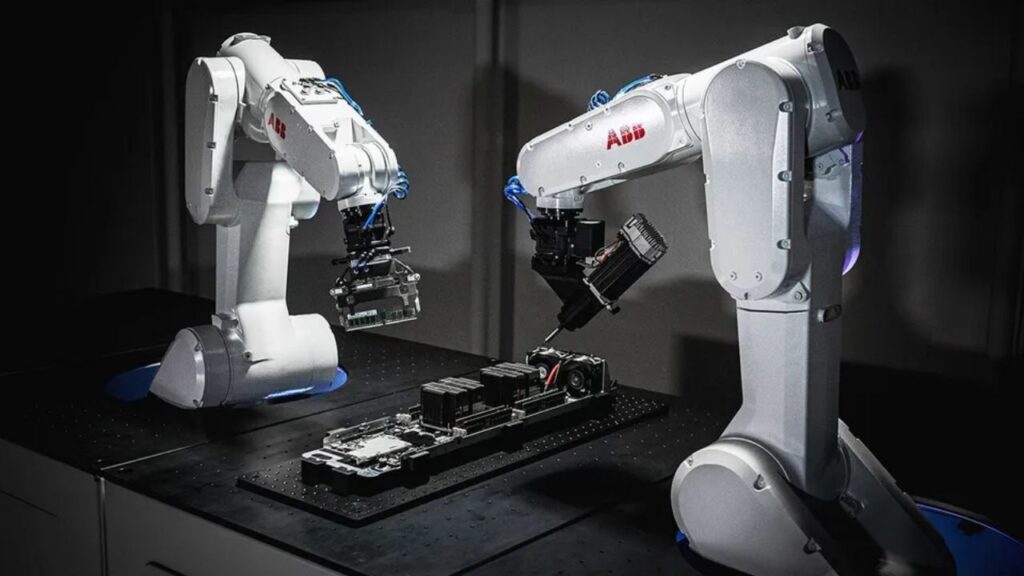

3. Automated Skill-Based Disassembly

The robot then executes the disassembly using advanced actuators and interchangeable tools. It can:

- Remove screws, rivets, and connectors

- Separate glued or soldered parts nondestructively

- Extract delicate components like motherboards and batteries with care

- Sort materials along the way for optimized recycling

For instance, Apple’s Daisy robot can dismantle 15 different iPhone models in under 18 seconds each, carefully removing 200 components without damage.

4. Material Recovery and Sorting

After disassembly, parts are sorted to distinguish metals, plastics, glass, and hazardous materials like lithium batteries. This precise sorting lets recycling facilities maximize the value extracted from e-waste and reduce harmful waste sent to landfills.

Real-World Examples of AI-Powered Disassembly Robots

Apple’s Daisy Robot

Launched in 2018, Daisy disassembles iPhones at a rate of 200 devices per hour. It can identify and remove specific parts like cameras, batteries, and speakers for efficient material recovery, enabling Apple to reuse materials in new products. Daisy combines AI vision, mechanical precision, and safe handling of hazardous components, marking a landmark in e-waste recycling.

Carnegie Mellon University’s roboLoop

This project focuses on flat panel displays and other fragile electronics. The robot uses AI to locate screws and remove them, speeding up disassembly while reducing manual labor. This project was inspired by CMU’s partnership with Apple and demonstrates the scalability of AI-powered recycling to devices beyond smartphones.

Fraunhofer Institute’s iDEAR Project

Scientists at Fraunhofer IFF in Germany are developing a comprehensive system combining AI, robotics, sensor scanning, and digital twin technology to automate e-waste disassembly for various consumer electronics. They aim to create adaptable robots able to dismantle everything from computers to household appliances nondestructively.

Practical Insights: What This Means for Users and the Industry

- For Recycling Facilities: AI-powered disassembly robots dramatically increase recycling speed, reduce labor costs, and enhance material purity, boosting economic incentives to recycle electronics responsibly.

- For Manufacturers: Robotics in recycling ensures valuable raw materials can be recovered and reused, reducing dependence on mining and raw resource extraction. This aligns with global sustainability goals.

- For Consumers: As recycling improves, the environmental footprint of electronic devices shrinks, encouraging more responsible consumption and disposal habits.

- For Policymakers: Supporting AI robotic recycling fosters green industry growth, job creation in high-tech fields, and progress toward circular economy mandates.

Robots Can Now Grow and Repair Themselves by “Eating” Other Machines—Science Fiction Is Real

Amazon Deploys Its 1 Millionth Robot and Launches New Generative AI Model for Smarter Warehousing

AI Just Got Smarter at Controlling Soft Robots — Here’s How It’s Learning to Move Like Humans

FAQs About AI-Powered Robots Can Now Take Apart Your Smartphone Piece By Piece

Q1: Why can’t traditional recycling methods correctly handle smartphones?

Traditional recycling often shreds electronics, causing valuable materials to mix and become harder to extract. Manual disassembly is slow and expensive. AI robots offer accurate, fast, and nondestructive disassembly for better recovery.

Q2: How do AI robots identify the different phone models and components?

Robots use AI-powered vision systems, 3D scanning, and sometimes X-ray imaging to analyze the phone’s structure and components, adapting disassembly plans based on the device.

Q3: What types of materials can be recovered?

Metals like gold, silver, copper; rare earth elements; plastics; glass; and batteries are separated for recycling or safe disposal.

Q4: Are there robots that can handle other e-waste besides smartphones?

Yes, projects like roboLoop focus on flat panel displays, while Fraunhofer develops robots for computers and home appliances. The goal is full automation across electronic product types.

Q5: How does this technology impact the environment?

By improving recycling rates and reducing hazardous waste, AI-powered disassembly robots help lower pollution and conserve finite natural resources.