Clean hydrogen energy is rapidly emerging as a key solution to combat climate change while meeting global energy demands. Traditionally, producing hydrogen, particularly green hydrogen via water electrolysis, has been expensive and challenging due to the reliance on costly catalysts like platinum and iridium. But in 2025, scientists have made major breakthroughs by discovering new, low-cost catalysts that are just as efficient but far more affordable. These discoveries promise to slash the cost of clean hydrogen production, making it accessible at an industrial scale and underpinning a greener energy future.

This article dives deep into the latest discoveries in catalysts for clean hydrogen energy, explaining what they are, why they matter, and how they’re set to transform the energy industry. Both beginners and professionals can gain valuable insights here, with clear explanations, practical examples, and verified facts.

Table of Contents

New Low-Cost Catalyst Discovered for Clean Hydrogen Energy

| Aspect | Details |

|---|---|

| Breakthrough Catalysts | Palladium Nanosheets, Boron-Doped Cobalt Phosphide, Multi-Metal Alloys |

| Efficiency | Comparable to platinum/iridium, up to 99.9% conversion efficiency |

| Cost Reduction | Lowered catalyst cost significantly by replacing precious metals with abundant alternatives |

| Stability | Durable under industrial acidic conditions |

| Global Investments | Projected jump to nearly $8 billion in low-emission hydrogen investment in 2025 |

| Applications | Clean fuel, energy storage, transportation, heavy industry |

| Official Research & Insights Link | International Energy Agency – The Future of Hydrogen |

The discovery of new low-cost catalysts for clean hydrogen energy in 2025 marks a transformative step toward a sustainable hydrogen economy. Catalysts like palladium-based nanosheets and boron-doped cobalt phosphide not only rival costly platinum and iridium in performance but also slash production costs and increase durability. These advancements are poised to accelerate the adoption of green hydrogen across multiple sectors, from transportation to heavy industry, helping to drastically cut greenhouse gas emissions worldwide.

With rising global investments in clean hydrogen and policies focused on decarbonizing energy systems, the future of hydrogen as a clean fuel looks brighter and more accessible than ever. For industries and professionals, embracing these catalysts could mean more affordable, efficient, and scalable clean energy solutions, contributing significantly to a zero-emission future.

Why Clean Hydrogen Energy?

Hydrogen energy is a clean fuel option that produces zero carbon emissions when burned. It’s lightweight and has more energy by weight than gasoline. This makes it perfect for heavy transport, industrial processes, and long-term energy storage, where battery-based solutions aren’t yet practical. But most hydrogen production today relies on fossil fuels—producing large amounts of CO2—and green hydrogen, made by splitting water with electricity from renewable sources, is costly.

The Basics: How Catalysts Help Make Clean Hydrogen

Hydrogen is commonly produced through electrolytic water splitting, where electricity splits water (H2OH2O) into oxygen (O2O2) and hydrogen gas (H2H2). This process has two major parts:

- Hydrogen Evolution Reaction (HER): Producing hydrogen gas at the cathode.

- Oxygen Evolution Reaction (OER): Producing oxygen gas at the anode.

Catalysts are materials that make these reactions faster and more efficient. The better the catalyst, the less energy is wasted, and the cheaper and cleaner the hydrogen produced.

However, the best catalysts, such as platinum or iridium, are extremely expensive and rare, limiting the widespread use of green hydrogen.

Breakthrough Catalysts Discovered in 2025

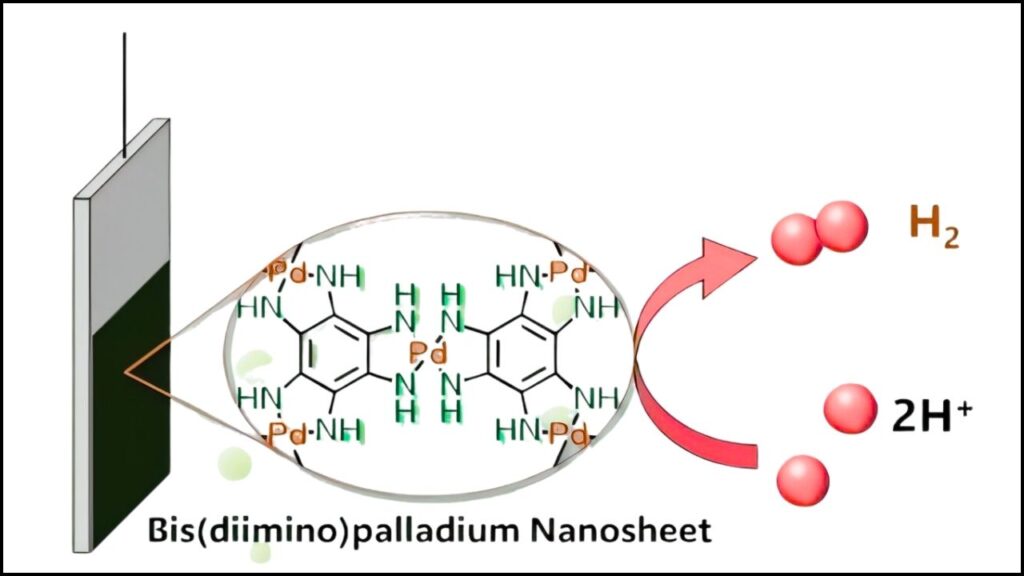

1. Palladium-Based Nanosheets: Affordable & Efficient

At the Tokyo University of Science, researchers developed a bis(diimino)palladium nanosheet (PdDI) catalyst that matches platinum’s efficiency but costs much less. This catalyst showed excellent durability—continuing to perform for 12 hours in acidic industrial settings—and uses ten times fewer precious metal atoms than platinum-based catalysts.

Why this matters:

- Reduces dependency on platinum, lowering costs.

- Offers a potential for large-scale industrial use due to durability.

- Aligns with United Nations’ Sustainable Development Goals for affordable and clean energy.

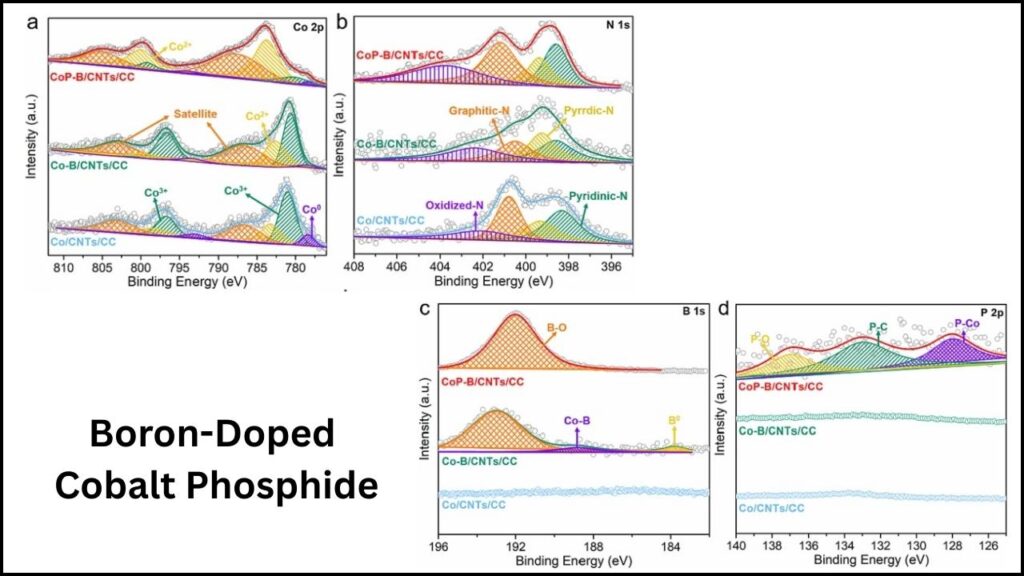

2. Boron-Doped Cobalt Phosphide: Tuning Performance and Reducing Costs

A team from Hanyang University in South Korea created a boron-doped cobalt phosphide nanosheet catalyst. By adjusting boron and phosphorus levels, they achieved a catalyst that works well for both hydrogen and oxygen evolution reactions, increasing overall efficiency and lowering material costs compared to traditional rare-earth catalysts.

Why this matters:

- Uses abundant and inexpensive materials.

- Improves performance for both sides of water splitting, enhancing overall system efficiency.

- Runs stably for over 100 hours, suitable for industrial applications.

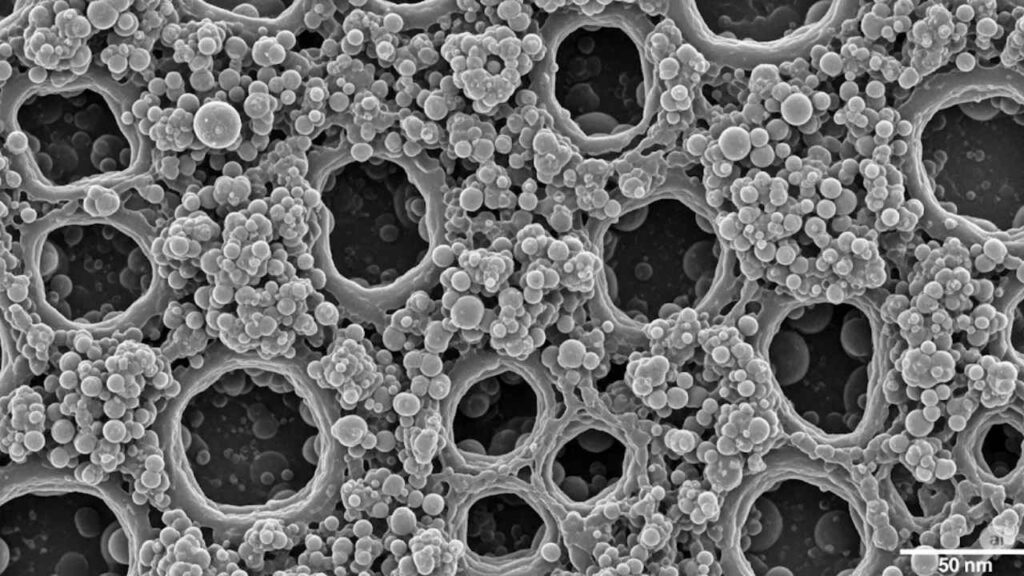

3. Multi-Metal Catalysts: Accelerating Discovery for Industrial Viability

Researchers at Northwestern University applied a cutting-edge nanoparticle “megalibrary” approach to discover multi-metal catalysts that outperform iridium in hydrogen evolution. Their rapid screening method identifies low-cost metal combinations with high catalytic activity, accelerating the search for scalable alternatives.

Why this matters:

- Bypasses the use of costly iridium.

- Rapidly identifies promising catalysts from common metal elements.

- Opens up opportunities for affordable green hydrogen in heavy industries.

How These Catalysts Could Change the Energy Landscape

Context of Hydrogen Market in 2025

Hydrogen production is dominated today by steam methane reforming (SMR), accounting for over 60% of global supply but producing significant CO2 emissions. Water electrolysis currently makes up only around 5% but is rapidly expanding due to environmental policies.

Costs for green hydrogen have been several times higher than fossil-derived versions, but these new catalysts, combined with scaling renewable electricity and electrolyzer improvements, could reduce prices dramatically.

Practical Benefits

- Lower Production Costs: These catalysts reduce dependence on precious metals, the most expensive part of electrolyzers.

- Cleaner Production: Efficient catalysts minimize electricity waste, improving overall sustainability.

- Broad Application: From powering hydrogen fuel cells in vehicles to decarbonizing steelmaking, these catalysts can unlock clean solutions.

Practical Guide: What This Means for Industry and Stakeholders

Step 1: Understand Electrolyzer Types and Catalysts Roles

- Alkaline electrolyzers are cheaper but less efficient; PEM (Proton Exchange Membrane) and SOEC (Solid Oxide Electrolyzers) offer better performance with precious-metal catalysts.

- The new catalysts like PdDI and boron-doped cobalt phosphide fit best with PEM electrolyzers, boosting affordability.

Step 2: Evaluate Catalyst Performance and Costs

- Focus on turnover frequency, overpotential, and durability data to compare catalysts.

- Prioritize options like PdDI for near-term commercial deployment due to its stability and proven results.

Step 3: Plan for Scale-Up and Integration

- Collaborate with catalyst manufacturers and electrolyzer producers for pilot testing.

- Consider government incentives and sustainability goals to support investments.

Step 4: Monitor Market and Policy Trends

- Keep an eye on international hydrogen strategies, regulatory frameworks, and subsidy programs to capitalize on growth opportunities.

This New Engine Cuts Emissions by 99% — Is Hydrogen Officially Dead?

Polish Mines May Turn Methane Into Hydrogen — A Game-Changer for Clean Energy?

Breakthrough Turns Sugarcane Waste Into Clean Hydrogen — With Almost Zero Emissions

FAQs About New Low-Cost Catalyst Discovered for Clean Hydrogen Energy

Q1: Why are catalysts so important in hydrogen production?

A: Catalysts speed up the water-splitting reactions to make hydrogen efficiently and cost-effectively, lowering energy demand and production costs.

Q2: How much cheaper can hydrogen get with these new catalysts?

A: While exact cost reductions vary, palladium nanosheets could reduce catalyst costs by up to 90% compared to platinum, potentially halving overall green hydrogen production costs.

Q3: Are these catalysts already commercially available?

A: Some catalysts like PdDI nanosheets are approaching commercialization, with ongoing pilot tests. Others are still in research but promising for near-future scaling.

Q4: What sectors benefit the most from clean hydrogen?

A: Heavy transportation, steel manufacturing, chemical industries, and energy storage benefit greatly thanks to hydrogen’s high energy density and clean emissions.

Q5: How do these catalysts align with sustainability goals?

A: They reduce the need for mined precious metals and enable more affordable green hydrogen, supporting UN goals for affordable, clean energy and industry innovation.