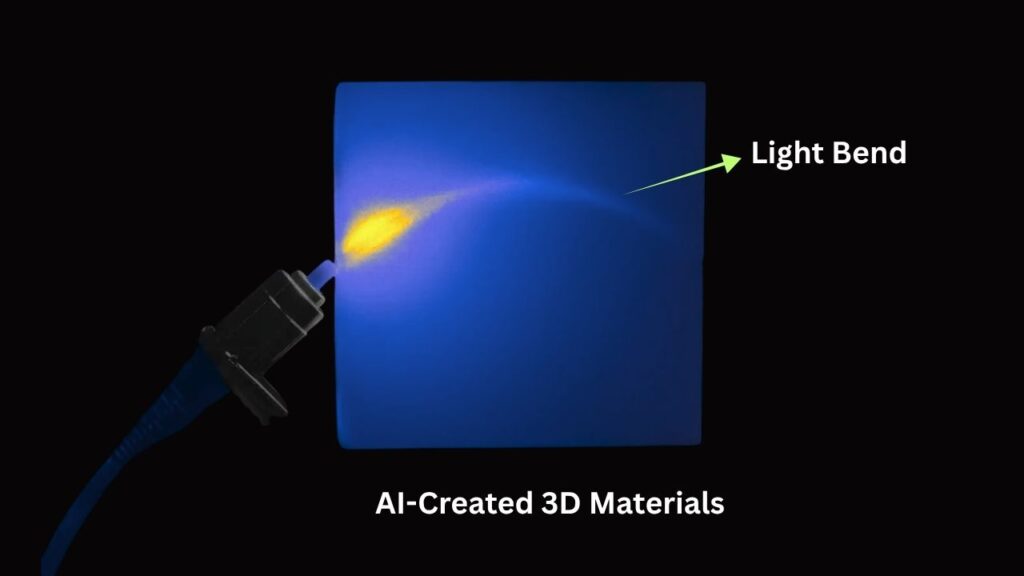

Manipulating light has always been fundamental to science and technology. From focusing sunlight with a glass lens to sending data through fiber optics, how light bends—or refracts—is crucial for countless devices. Now, a team of researchers at UCLA has developed a groundbreaking method using AI-designed 3D materials to control light bending in ways never seen before. Their innovative device, called a refractive function generator (RFG), enables programmable, customizable light steering, opening new doors for optical computing, communication, and imaging technologies.

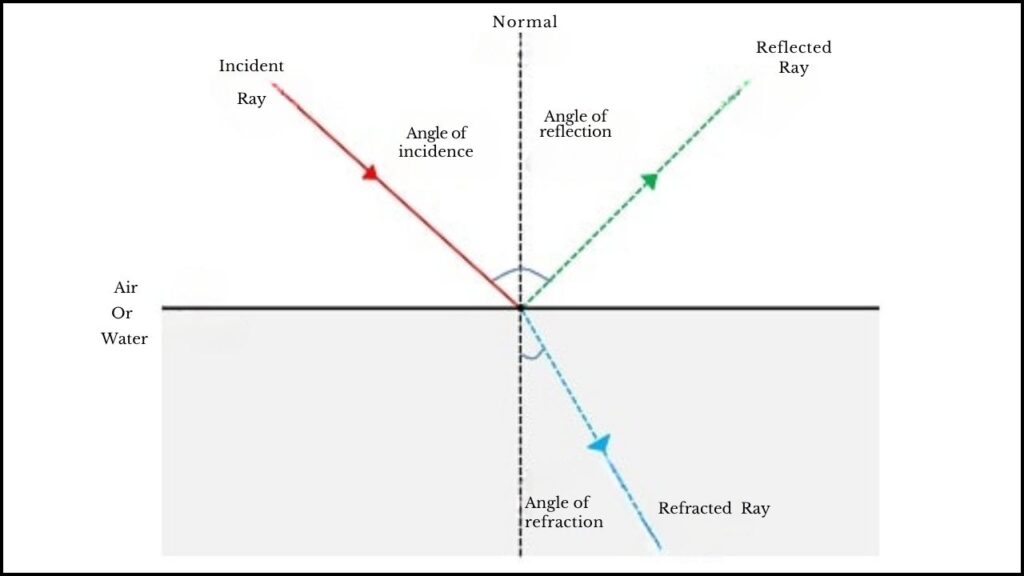

Traditional refraction follows physical laws, determined by Snell’s Law, which fixes the relationship between the angle at which light enters a material and the angle at which it leaves, based on the material’s optical properties. Conventional materials, from simple glass to advanced metasurfaces, only allow limited control of light bending.

The UCLA team, led by Chancellor’s Professor Dr. Aydogan Ozcan, has shattered these limitations by using artificial intelligence to design thin stacks of specially structured transmissive layers. These materials are 3D-printed at scales close to the wavelength of light, enabling unprecedented, programmable refraction. That means the material can bend light differently depending on the incoming direction, allowing fully custom control over light paths.

Table of Contents

AI-Created 3D Materials

| Feature | Description |

|---|---|

| Technology | AI-designed 3D refractive function generator (RFG) |

| Principal Investigator | Dr. Aydogan Ozcan, Chancellor’s Professor, UCLA Samueli School of Engineering |

| Material Fabrication | 3D-printed layers at near-wavelength scale |

| Light Control | Arbitrary, independent control over light bending for each incoming direction |

| Testing | Demonstrated with terahertz waves |

| Applications | Optical computing, advanced imaging, communication systems |

| Scientific Publication | Published in Nature Communications |

| Official Website | UCLA Samueli School of Engineering |

| Funding | Supported by the US Army Research Office |

The UCLA research team has pioneered the development of AI-designed 3D refractive function generators that redefine how we manipulate light. By breaking free from traditional optical laws and enabling arbitrary, programmable refraction, this technology sets the stage for revolutionary advances in computing, imaging, and communication systems. Compact and fabricated through scalable 3D printing, these devices promise broad accessibility, potentially transforming many high-tech fields.

What Is Refraction and Why Does It Matter?

Refraction is the bending of light as it moves from one material into another; it’s why a straw looks bent in a glass of water or how lenses focus light to create images. The angles of entering and exiting light rays traditionally follow fixed rules governed by the material’s refractive index and Snell’s law.

However, these fixed laws limit our ability to control light’s path. For decades, researchers have sought to design special surfaces—called metasurfaces—to manipulate refraction, but improvements have been incremental.

Imagine being able to bend light freely, controlling it precisely in any direction regardless of how it arrives. This could revolutionize:

- Optical computing, where light carries and processes information faster and more efficiently than electrical signals.

- Advanced imaging systems that see with high clarity even in challenging environments like fog or through complex materials.

- Communication technologies that precisely direct light signals, improving data transfer speed and security.

The UCLA research team’s refractive function generator takes us to this new frontier.

The Innovation: AI-Designed 3D Refractive Function Generator (RFG)

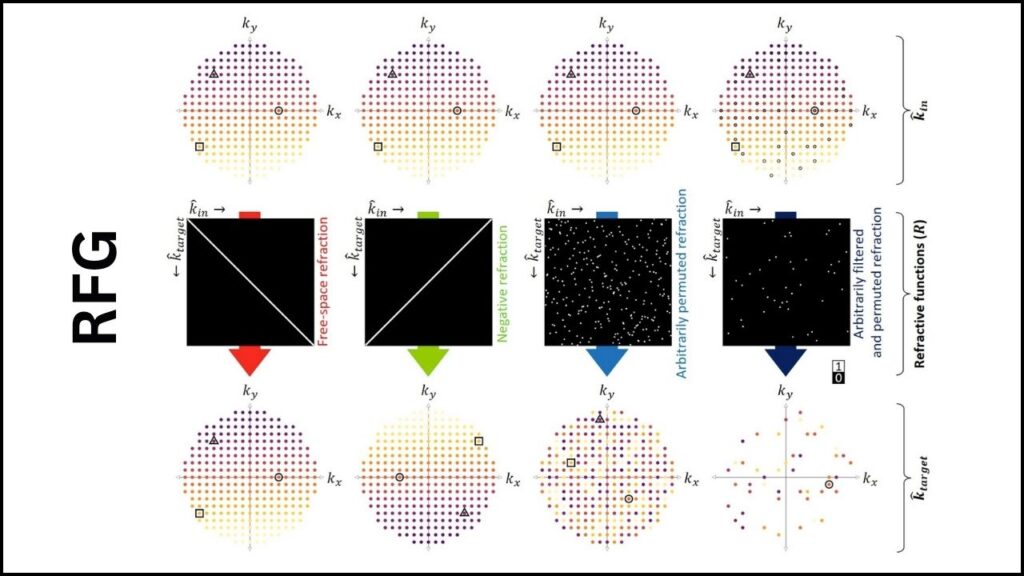

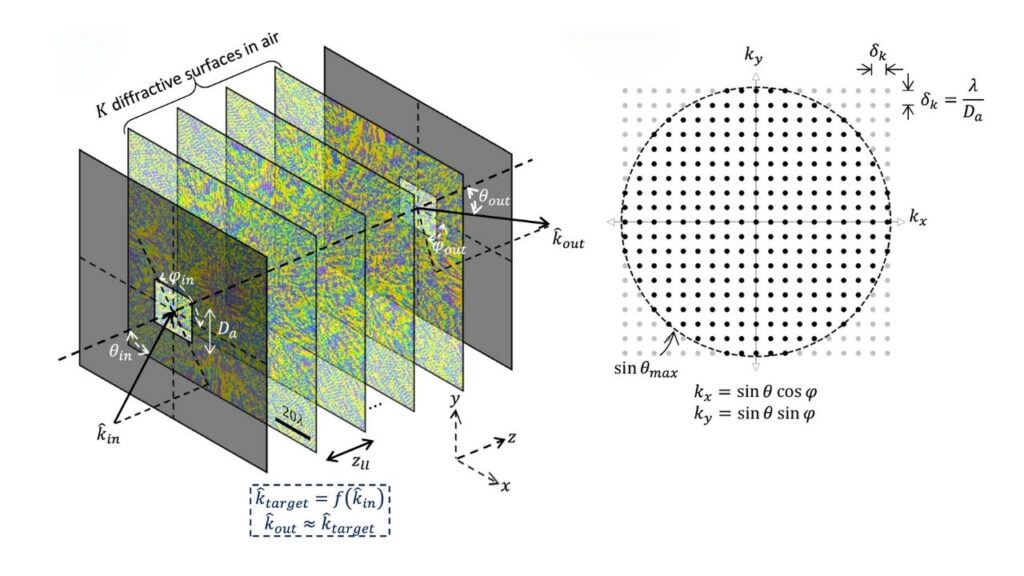

The RFG is a thin stack of passive, transmissive layers, architected at nearly the scale of light waves (sub-wavelength scale). What sets the RFG apart are these key features:

- AI-Driven Design: Deep learning algorithms optimize the internal 3D structure to produce exact, programmable light-bending functions, tailored for each direction light may enter.

- Programmable Refraction: Unlike traditional materials with fixed bending rules, the RFG’s structure enables arbitrary, independent control of refraction for every input angle.

- Compactness and Robustness: The device is only a few tens of wavelengths thick, making it thin and compact, yet tolerant to fabrication imprecisions and wavelength variations.

- 3D Printing Fabrication: These complex internal structures are realized with precision 3D printing technology, translating AI designs into physical devices.

How Does It Work? A Simplified Explanation

- Light Arrives: Light waves come from various directions towards the surface.

- AI Optimization: Deep learning designs how the layered structure inside the RFG should look for bending light exactly as desired from each direction, independent of others.

- 3D Printing: The AI-designed internal structure is created using high-resolution 3D printing.

- Light Passes Through: Each transmissive layer interacts with the incoming light wave, collectively steering it according to the programmed function.

- Controlled Output: The exiting light demonstrates completely customized refraction — programmable patterns impossible with classical optics.

Practical Applications and the Future Impact

The impact of this breakthrough could be transformative in many areas:

Optical Computing

RFG devices can steer light signals arbitrarily, enabling circuits that use photons instead of electrons. This could dramatically increase processing speeds while cutting energy consumption.

Advanced Imaging and Sensing

Devices using programmable refraction can generate tailored illumination and imaging schemes, enhancing medical imaging, environmental sensing, and even seeing through obscurants.

Communication Systems

Precise light bending enhances fiber optic networks and free-space optical communication by dynamically steering signals, increasing bandwidth, and security.

Scalable, Economical Production

Because the RFGs are passive, use 3D printing, and rely on AI to optimize their structure, they can be produced efficiently and cost-effectively, making advanced optics accessible for a wide range of industries.

Scientists Use DNA as a Building Block to Create Customized 3D Materials with Unique Properties

Game-Changing 3D Printing Breakthrough Lets Scientists Combine Multiple Materials in One Build

Ultralight 3D-Printed Antennas Cut Weight By 94 Percent With Breakthrough Multi-Material Design

FAQs About AI-Created 3D Materials

Q1: How is the RFG different from traditional lenses?

Traditional lenses bend light uniformly based on fixed properties, following Snell’s law. The RFG, however, bends light arbitrarily, with programmable control for each incoming direction, enabling light manipulation beyond classical limits.

Q2: What light frequencies does this technology support?

Initial prototypes operated at terahertz frequencies, but the design principles extend to visible, infrared, and other wavelengths.

Q3: How is AI utilized in this research?

Artificial intelligence algorithms, particularly deep learning, design the internal 3D structure by optimizing the material’s refractive properties for programmable light control.

Q4: Can RFGs be manufactured at scale?

Yes. The devices use 3D printing and scalable fabrication methods, allowing low-cost, high-volume production.

Q5: Who benefits most from this technology?

Telecommunications, optical computing, medical imaging, augmented reality, and scientific research industries stand to gain significantly.