European Startups Achieve Breakthroughs in Recycling EV Battery Materials: European startups achieve breakthroughs in recycling EV battery materials, a pivotal shift that is reshaping the electric vehicle (EV) industry and strengthening Europe’s green transition. As the demand for EVs rises, so does the need for smarter ways to deal with battery waste. Europe is turning to its own innovators to build a circular, sustainable battery economy.

With the EU aiming to reach climate neutrality by 2050, recycling lithium-ion batteries is now a strategic necessity. These batteries contain critical raw materials like lithium, cobalt, nickel, and graphite — all of which are expensive, environmentally costly to extract, and often imported. By recovering and reusing these materials, startups across Europe are creating powerful solutions to environmental, economic, and supply chain challenges.

Table of Contents

European Startups Achieve Breakthroughs in Recycling EV Battery Materials

| Feature | Details |

|---|---|

| Primary Topic | Recycling EV Battery Materials in Europe |

| Key Startups | Altilium (UK), tozero (Germany), Cylib (Germany), Circu Li-ion (Luxembourg), Northvolt (Sweden) |

| Environmental Impact | Up to 70% CO₂ reduction (Altilium), net-zero recycling (tozero), fully closed-loop batteries (Northvolt) |

| Funding Examples | €17 million (tozero), €8.5 million (Circu Li-ion), €1 billion+ (Northvolt) |

| Industrial Collaboration | Jaguar Land Rover, Porsche, Bosch, Volvo |

| EU Regulation | By 2030, EV batteries must contain 6% recycled lithium, 6% nickel, 16% cobalt |

| Official EU Info | ec.europa.eu/environment |

European startups are rewriting the rulebook on EV battery recycling, creating smarter, cleaner, and more circular supply chains. With strong support from regulators, automakers, and investors, this ecosystem is poised to secure Europe’s leadership in sustainable battery tech.

As 2030 deadlines draw near, those who invest in or adapt to this shift will drive both environmental progress and long-term profitability.

Why Battery Recycling Matters for Europe’s Future

The world is undergoing an electric revolution. According to the International Energy Agency (IEA), global demand for EV batteries will grow by 25 times by 2040. With more EVs hitting the road, the number of batteries reaching end-of-life is increasing rapidly.

This brings two major concerns:

- Environmental: Mining raw materials generates large carbon footprints and causes habitat destruction.

- Geopolitical: Europe imports most of its battery materials from countries like China, Chile, and the Democratic Republic of Congo.

Battery recycling is the key to reducing emissions, costs, and import dependencies — while helping Europe build a resilient and secure green economy.

Spotlight on the Startups Revolutionizing Battery Recycling

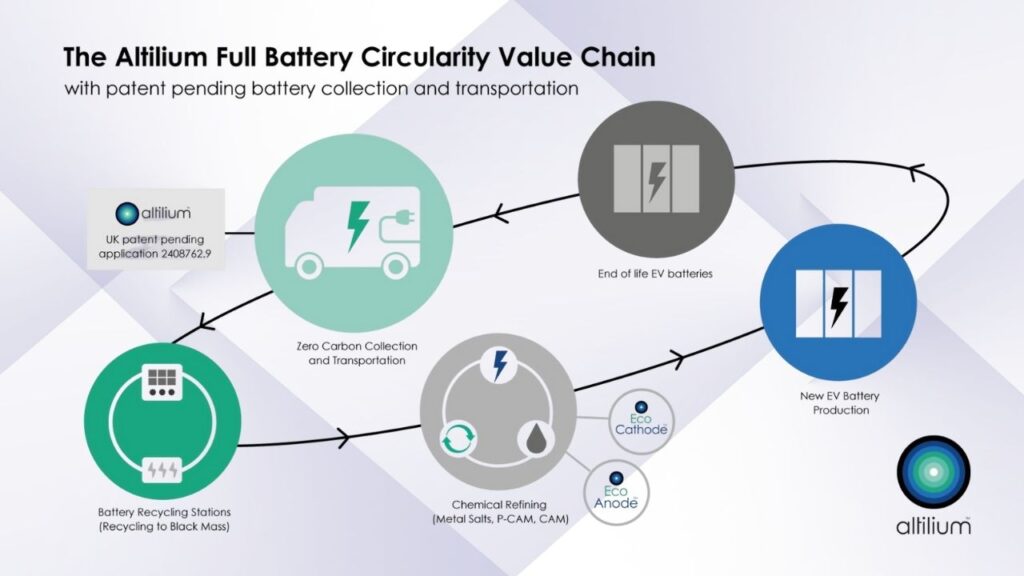

Altilium (UK): Greener Batteries from Waste

Altilium is pioneering recycled cathode active materials (CAMs) in partnership with Imperial College London. These materials match the quality of newly mined resources but with a much smaller carbon footprint.

- CO₂ reduction: Up to 70%

- Cost savings: Up to 20%

- Key partnership: Jaguar Land Rover, for its electric I-PACE model

- Plant location: Teesside, UK – with capacity to supply 150,000 EVs/year

tozero (Germany): Recovering Forgotten Graphite

While most focus on lithium and cobalt, graphite makes up 40% of a battery’s mass and CO₂ footprint. tozero uses an innovative hydrometallurgical process to recover graphite and other critical materials — with zero emissions when powered by renewables.

- Funding raised: €17 million

- Partners: Honda and other OEMs

- Capacity target: 2,000 tonnes/year of recycled graphite by 2027

Cylib (Germany): Full-Spectrum Eco Recycling

Supported by Porsche and Bosch, Cylib aims to recover almost every component of a used battery, from lithium to plastic casings. Their green process avoids harmful chemicals and maximizes efficiency.

- Facility: Dormagen, Germany

- Annual throughput: 30,000 tonnes

- Special advantage: Eco-safe chemical-free separation process

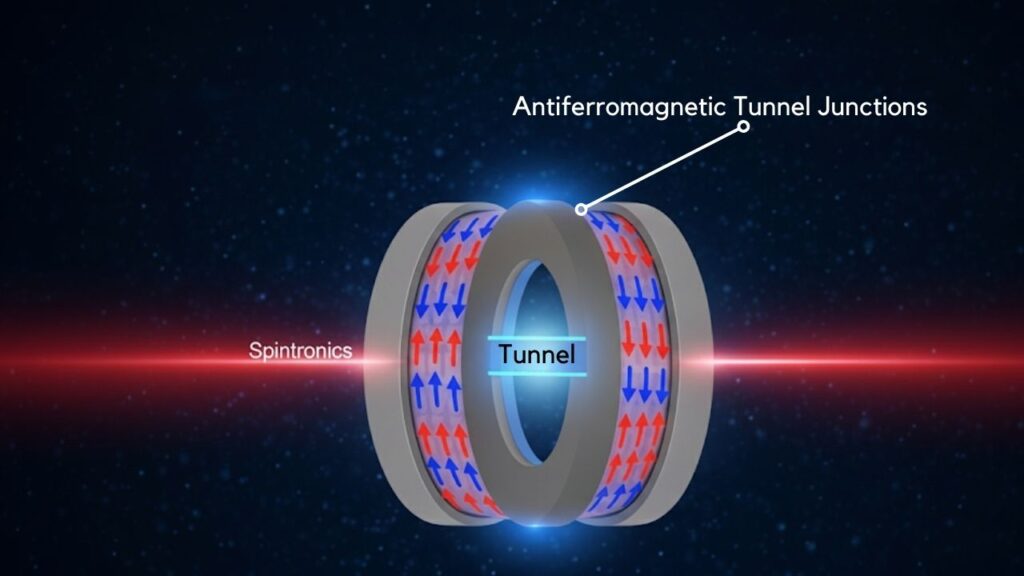

Circu Li-ion (Luxembourg): AI Meets Battery Waste

Circu Li-ion uses robotics and AI to automate the disassembly, sorting, and diagnosis of used battery cells. It determines which cells are reusable and extracts healthy ones — optimizing reuse and reducing waste.

- Goal: Recycle 3 billion cells by 2035

- CO₂ savings: Up to 48%

- Funding: €8.5 million seed round

Northvolt (Sweden): The Closed-Loop Pioneer

Northvolt stands out as one of the first European battery makers to implement fully closed-loop battery manufacturing. Through its “Revolt” recycling program, Northvolt recycles all battery waste from its own production line.

- Facility: Revolt Ett (Sweden)

- Recycled content: 100% nickel, manganese, and cobalt recovered

- Partnerships: Volvo, BMW

- Funding: Over €1 billion from public and private sectors

New EU Battery Regulations You Should Know

The EU Battery Regulation (2023) is forcing change in the industry. By 2030:

- All EV batteries must contain:

- 6% recycled lithium

- 6% recycled nickel

- 16% recycled cobalt

- Companies must track carbon footprints for battery production.

- Stricter collection targets will be enforced: at least 70% of batteries collected by 2030.

Business Opportunities and Practical Guidance

Startups and enterprises can benefit in several ways:

For Manufacturers

- Reduce costs by up to 20% using recycled inputs

- Meet ESG goals to attract investors and buyers

- Enhance supply security by localizing material sourcing

For Researchers & Innovators

- Explore next-gen hydrometallurgy

- Apply AI in diagnostics and automation

- Partner with EU-funded pilot projects (Horizon Europe)

For Investors

- Target startups focused on automation, emissions-free processing, or end-to-end reuse

- Look for EU Green Deal-aligned ventures

Challenges in Battery Recycling

While the promise is clear, challenges remain:

- Battery Design: Many EV batteries are not made for easy disassembly

- Chemical Hazards: Recycling requires handling flammable and toxic materials

- Logistics: Collecting used batteries across borders is costly and complex

- Regulatory Inconsistencies: Some EU member states lag in implementation

Timeline: Battery Recycling Progress at a Glance

| Year | Milestone |

|---|---|

| 2020 | Northvolt launches Revolt recycling program |

| 2022 | EU proposes new battery regulation |

| 2023 | EU regulation passed with circular economy targets |

| 2024 | Cylib breaks ground on 30,000-tonne facility |

| 2025 | Altilium supplies recycled CAMs to Jaguar Land Rover |

| 2027 | tozero’s graphite recycling plant launches |

| 2030 | EU mandates minimum recycled content in all EV batteries |

How Battery Recycling Works (Simplified)

Step 1: Collection

Old or damaged batteries are gathered from garages, dealerships, or decommissioned EVs.

Step 2: Disassembly

Manual or robotic disassembly separates cells, plastics, and metals.

Step 3: Extraction

Chemicals or thermal processes extract lithium, cobalt, nickel, graphite, and other components.

Step 4: Refining

Materials are purified and converted into high-grade compounds for new battery production.

Tech Meets Textiles: Smart Fabrics That Monitor Health and Power Devices

Can DNA Store the Internet? Exploring Molecular Data Storage Technologies

China’s Tianwen-2 Mission Launches to Retrieve Asteroid Samples and Explore Comet

FAQs About European Startups Achieve Breakthroughs in Recycling EV Battery Materials

What are the benefits of battery recycling?

Reduces emissions, cuts raw material dependency, saves costs, and supports EU climate goals.

Are recycled batteries as good as new ones?

Yes. Startups like Altilium produce CAMs that match or exceed the quality of virgin materials.

Can private consumers recycle their EV batteries?

Yes, but it must be done via authorized service centers or automaker partnerships.

Is the EU funding battery recycling innovation?

Yes. Programs like Horizon Europe and the European Battery Alliance fund R&D and infrastructure.