Breakthrough Carbon Capture Method: Breakthrough carbon capture method could make cement ingredients climate-friendly is more than a headline—it’s a sign of real hope in the fight against climate change. Cement, a vital building material used around the world, is one of the largest industrial sources of carbon dioxide (CO₂) emissions. In fact, the cement industry is responsible for around 8% of global CO₂ emissions. But thanks to a wave of innovative carbon capture technologies, there’s a serious push to make cement production cleaner and more sustainable.

This article breaks down the latest developments, including Fortera’s ReAct® technology, Norway’s full-scale carbon capture cement plant, and alternative low-carbon cement formulas. It offers clear insights, examples, and actionable steps for professionals, students, and anyone interested in the future of sustainable construction.

Breakthrough Carbon Capture Method

| Topic | Details |

|---|---|

| Cement Emissions | Cement production accounts for ~8% of global CO₂ emissions |

| Fortera’s ReAct® Technology | Captures CO₂ and reuses it to make cementitious materials |

| First ReAct® Plant | Redding, California (15,000 tons/year capacity) |

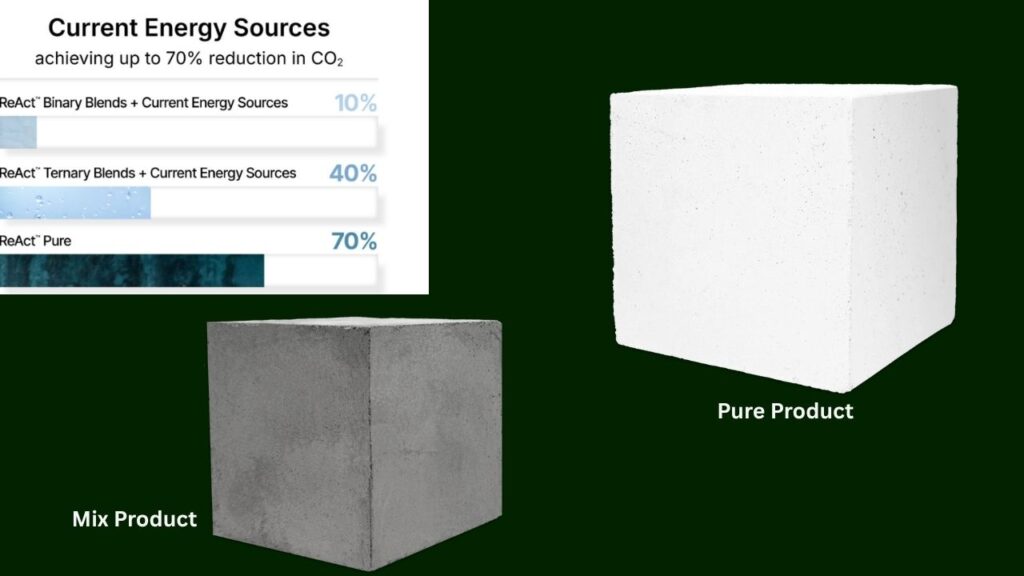

| Emission Reduction | Up to 70% CO₂ reduction per ton of cement |

| Global Projects | Norway (Norcem Brevik), Australia (MCi Carbon), India (LC³ Trials) |

| Official Source | Fortera Website |

Carbon capture and alternative cement formulations are bringing real solutions to one of the toughest climate challenges: cement production. Companies like Fortera and Norcem are proving that we don’t have to choose between building and sustainability. With the right mix of policy support, industry collaboration, and public awareness, we can pave the way for climate-friendly cement worldwide.

Why Cement Is a Climate Problem

Cement is a critical material in construction, used to bind sand, gravel, and water into concrete. But making cement requires heating limestone (calcium carbonate) to very high temperatures, which releases large amounts of CO₂ both from burning fuel and from chemical reactions.

- Process emissions: When limestone is heated, it decomposes into lime (CaO) and CO₂. This accounts for more than half of the emissions.

- Fuel emissions: The kilns used for heating are often powered by coal or natural gas, adding even more CO₂.

Together, these processes make the cement industry one of the most carbon-intensive sectors on the planet.

Fortera’s ReAct® Carbon Capture Technology

Fortera, a U.S.-based climate tech company, has developed a revolutionary process that captures CO₂ from cement plants and turns it into a new cement-like material. Their system, known as ReAct®, integrates directly into existing cement manufacturing operations.

How It Works:

- Capture: CO₂ is captured from the exhaust gases of cement kilns.

- React: The CO₂ is mineralized by reacting it with calcium oxide to form a new calcium carbonate compound.

- Produce: The resulting material is used as a supplementary cementitious material or even a full cement replacement.

Why It Matters:

- Retrofittable: Fortera’s tech can be added to existing cement plants, avoiding the need for full rebuilds.

- Low Energy Demand: The process works at lower temperatures than traditional cement making.

- Scalable: Fortera aims to scale the ReAct system globally.

In 2024, Fortera launched its first commercial facility in Redding, California. This plant can produce 15,000 tons of cement annually and capture about 9,600 tons of CO₂ each year.

Global Carbon Capture Initiatives in Cement

Norway: Norcem Brevik Project

- Operator: Norcem, part of Heidelberg Materials.

- Capacity: Designed to capture 400,000 tons of CO₂ annually.

- Technology: Full-scale post-combustion carbon capture.

- Timeline: Operations expected to begin in 2025.

- Significance: First fully integrated CCS (carbon capture and storage) solution in a cement plant.

Australia: MCi Carbon

- Technology: Captures CO₂ and converts it into solid materials like calcium carbonate.

- Applications: Used in construction products like bricks, plasterboard, and tiles.

- Pilot Plant: “Myrtle” plant under development with support from the Australian government.

Alternative Low-Carbon Cement Blends

In addition to carbon capture, scientists and engineers are developing new types of cement that require less energy and produce less CO₂.

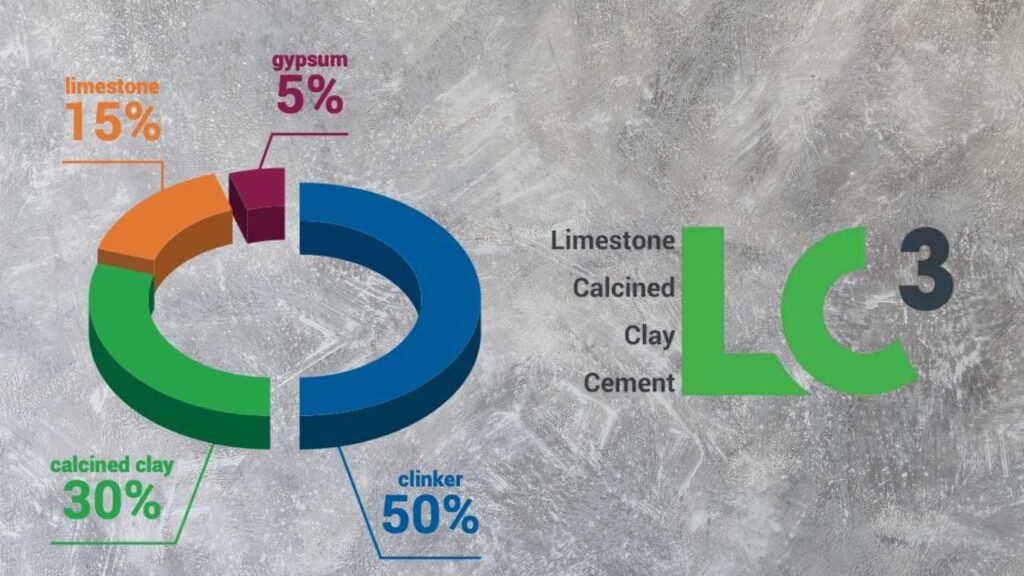

LC³: Limestone Calcined Clay Cement

- Developed by researchers at EPFL and IIT-Madras.

- Replaces up to 50% of the traditional clinker with limestone and calcined clay.

- Reduces emissions by 30–40%.

- Already being tested in countries like India, Cuba, and Kenya.

Electrochemical Cement

- Uses electrolysis to produce lime without releasing CO₂.

- Still in the experimental stage.

- Could offer up to 95% emission reductions if scaled.

Challenges to Adoption

While the technologies are promising, several challenges need to be addressed:

1. High Costs

- Carbon capture systems are expensive to install.

- Low-carbon cements may cost more initially.

2. Regulatory Barriers

- Many countries have strict standards that don’t yet recognize alternative cements.

3. Market Acceptance

- Builders and contractors may be hesitant to adopt new materials without long-term performance data.

4. Infrastructure Needs

- Carbon capture requires pipelines and storage infrastructure, which are not available everywhere.

How Industry Professionals Can Act

If you work in construction, engineering, architecture, or environmental policy, here are steps you can take:

- Use blended cement with lower clinker content.

- Request low-carbon products from suppliers.

- Support pilot projects and trials of new technologies.

- Engage in policy: Advocate for standards that support innovation.

- Educate clients: Share the long-term climate and financial benefits of low-carbon materials.

CO₂ to Methane Conversion Unlocked by Tweaking Nickel Nanoparticle Shape

Strange Memory Effect Found Controlling Quantum Atomic Motion on Metals

Bigger Molecules Now Proven to Extend Quantum Charge Flow Like Never Before

FAQs About Breakthrough Carbon Capture Method

Q1. Why does cement production emit so much CO₂?

Because both the chemical reaction involved in making cement and the fuel burned in kilns release carbon dioxide.

Q2. Is low-carbon cement as strong as regular cement?

Yes, many alternatives like LC³ and Fortera’s ReAct® meet or exceed traditional strength requirements.

Q3. Can existing plants use carbon capture technology?

Yes, technologies like Fortera’s are designed to be added to current plants without full reconstruction.

Q4. Are these technologies already in use?

Yes. Fortera’s first plant is operational in California. Norway’s Norcem project will launch soon.

Q5. How can governments support cleaner cement?

Through subsidies, carbon pricing, updated standards, and funding for innovation.