Imagine a world where you can fly from city to city, not just quickly and comfortably, but with no impact on the climate—no smoke, no greenhouse gases, just the sound of quiet electric motors and the sight of clouds drifting by. This vision, once dismissed as science fiction, is now a serious engineering project, with Coventry University and its partners leading the charge. Carbon-zero aircraft—planes that produce no net carbon dioxide emissions during flight—are becoming a realistic goal, thanks to breakthroughs in hydrogen fuel cell technology and the UK’s commitment to green innovation.

Table of Contents

Why Carbon-Zero Aviation Matters

The urgency of climate action is now a global priority. While cars, buses, and even ships are starting to transition to electric and hydrogen power, aviation has lagged behind. Air travel accounts for about 2–3% of global CO₂ emissions, but its impact is growing, and it’s a sector that’s especially hard to decarbonize. Jet engines are optimized for the energy density of fossil fuels, and batteries, while suitable for small drones and very light aircraft, are simply too heavy for most commercial and passenger flights.

Sustainable Aviation Fuels (SAFs)—made from plants or waste—can cut emissions by up to 80% compared to conventional jet fuel, but they are not a perfect solution. They still release some CO₂ and require vast amounts of land, water, and energy to produce. Hydrogen, on the other hand, can be made from water using renewable electricity, and when used in fuel cells, it produces only water vapor as a byproduct—a true zero-emission solution.

Coventry University is at the heart of a UK-wide push to turn this vision into reality, working alongside industry leaders and supported by major government investment.

Carbon-Zero Aircraft

| Aspect | Details | Data/Stats | Career & Professional Opportunities |

|---|---|---|---|

| Carbon-Zero Aircraft | Coventry University partners with Intelligent Energy and ZeroAvia on advanced fuel cell projects | HEIGHTS project: £17m+; AFCAD: £10.5m; UK total: £84m+ | Electrochemical, aerospace, manufacturing, data science |

| Core Technology | Hydrogen fuel cells (HTPEM for larger aircraft, regular PEM for lighter craft) | Zero CO₂, water vapor only, higher power-to-weight ratio | Fuel cell engineering, aviation systems, diagnostics |

| Aircraft Types | First: eVTOLs (flying taxis, drones), then small regional, eventually larger commercial aircraft | eVTOLs as early as late 2020s; regional 2030s; commercial uncertain | Pilots, maintenance, avionics, hydrogen infrastructure |

| Research Focus | In-situ fuel cell health monitoring, reliability, safety, high-performance diagnostics | Embedded sensors, real-time analytics, aviation-grade testing | Instrumentation, reliability engineering, test pilots |

| UK Leadership | Part of national “Jet Zero” strategy; three major projects funded; supply chain and jobs focus | Government investment, cross-industry collaboration | Engineers, technicians, policy, infrastructure planning |

Carbon-zero aircraft are no longer a dream—they are a serious, achievable engineering goal, and Coventry University is at the center of UK efforts to make it a reality. By focusing on hydrogen fuel cell technology, developing advanced health monitoring, and working with industry partners, Coventry is helping to create the aircraft, the sensors, and the workforce that will power the zero-emission flights of the future.

The transition won’t happen overnight, and many challenges remain—especially for long-haul commercial jets. But for smaller aircraft, urban air mobility, and regional flights, zero-emission aviation is within reach this decade, with the UK poised to lead the way.

If you’re interested in a career on the cutting edge of green technology, or simply want to understand how we’ll fly cleanly in the years ahead, there’s never been a more exciting time to get involved—and Coventry is helping to build it all, step by step.

Understanding the Technology

Why Hydrogen Fuel Cells?

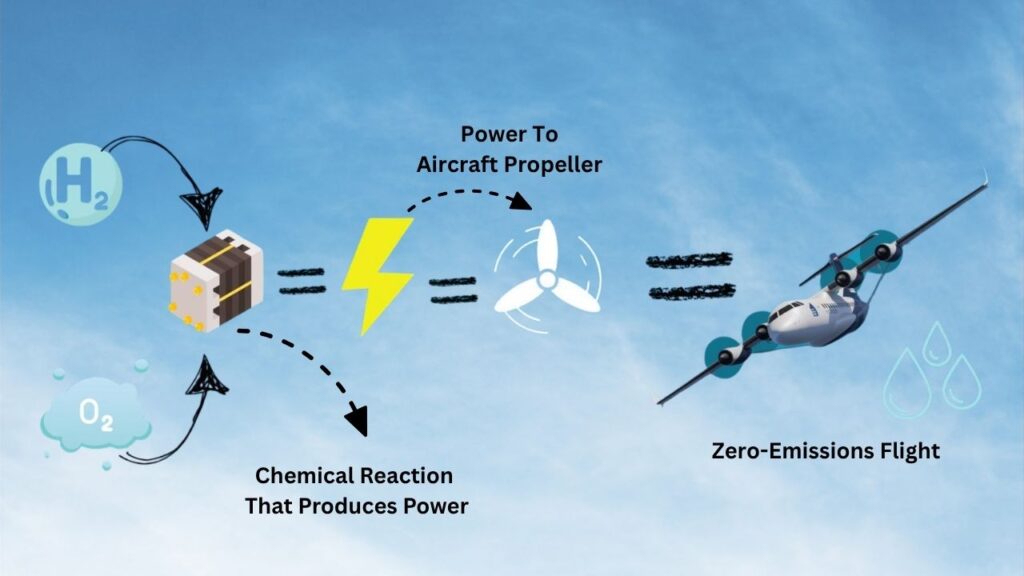

Hydrogen fuel cells are devices that generate electricity through a chemical reaction between hydrogen and oxygen. Unlike a battery, which stores electricity, a fuel cell produces it on demand, as long as hydrogen is supplied. The only byproduct is water vapor. There’s no combustion, no CO₂, and—if the hydrogen is made using renewable energy—no carbon footprint at all.

In aviation, where every gram counts, hydrogen’s high energy-to-weight ratio makes it a uniquely strong candidate. Batteries, even the best lithium-ion types available today, are simply too heavy for anything beyond small, short-range aircraft. Hydrogen, even when stored as a gas or in advanced lightweight tanks, delivers much more energy per kilogram.

The Challenges of Hydrogen Aviation

Despite its promise, hydrogen aviation is not without hurdles:

- Storage: Hydrogen must be stored at very low temperatures (as a liquid) or under high pressure (as a gas), both of which require robust, lightweight tanks.

- Infrastructure: Airports, like today’s gas stations, would need to be equipped to handle hydrogen refueling, which is more complex and requires new safety protocols.

- Safety: Hydrogen is flammable, but so is jet fuel. Modern engineering ensures that hydrogen can be handled safely, with leak detection, automatic shutoffs, and flame arrestors.

- Performance: For commercial jets, fuel cells must deliver very high power, last thousands of hours between overhauls, and be reliable in all weather conditions.

Coventry University’s research—focused on reliability, health monitoring, and performance optimization—is tackling these challenges head-on.

Coventry’s Role in Detail

The HEIGHTS Project

The HEIGHTS project is a multi-partner initiative led by Intelligent Energy, with Coventry University playing a central role. The project is funded by the UK government’s Aerospace Technology Institute (ATI) Programme, with over £17 million in support.

Coventry’s Contribution: The university’s specialists are developing advanced health monitoring and diagnostics for these fuel cells. Essentially, they are building “smart” fuel cells that can sense their own condition in real time, much like how your smartphone monitors its battery. For aviation, this is crucial—planes can’t pull over if something goes wrong, so every system must be designed for ultra-high reliability.

Goal: To develop a fuel cell system that is aviation-grade—meaning it’s reliable, powerful, and safe enough for use in aircraft, first targeting electric vertical take-off and landing (eVTOL) vehicles (think flying taxis), and eventually scaling up to larger regional aircraft.

The sensors Coventry is embedding directly into the fuel cells monitor temperature, pressure, humidity, and electrical performance. If any parameter drifts out of a safe range, the system can alert pilots and ground crews, or even take automatic corrective action. This level of in-situ monitoring is new for aviation fuel cells and is a direct result of Coventry’s expertise in battery and fuel cell reliability.

The AFCAD Project

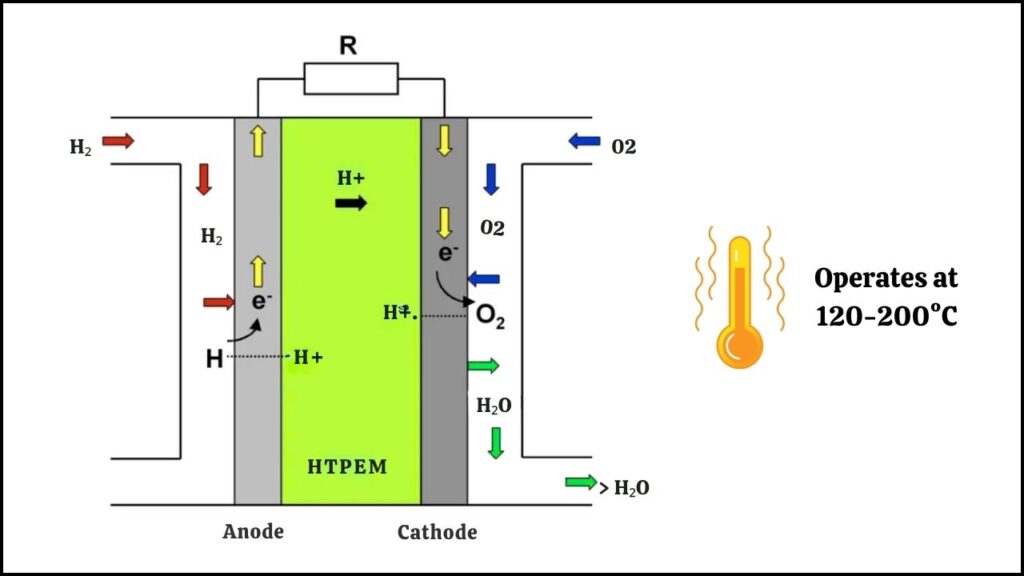

In parallel, Coventry is working with ZeroAvia on the AFCAD (Advanced Fuel Cell for Aviation Decarbonisation) project, which is developing high-temperature proton exchange membrane (HTPEM) fuel cells for larger passenger aircraft.

Why High-Temperature? Most automotive fuel cells work at relatively low temperatures. For aviation, where power demands are much higher, HTPEM technology can deliver more energy, last longer, and cope with the harsh conditions of flight—vibration, temperature swings, and rapid changes in altitude.

Coventry’s Team is responsible for detailed, real-time measurement and analysis of these fuel cells. Rather than just looking at the voltage or current output, they are instrumenting the cells to measure internal components, temperatures, gas flows, and efficiency throughout every phase of operation. This data is critical for optimizing performance, predicting maintenance needs, and ensuring that the system meets the demanding safety standards of commercial aviation.

The Broader UK Context

Coventry University’s work is just one part of a broad, coordinated UK effort to lead the world in zero-emission aviation. Three major hydrogen aviation projects—HEIGHTS, AFCAD, and H2GEAR (led by GKN Aerospace)—are underway, representing a total government and industry investment of over £84 million.

- H2GEAR focuses on liquid hydrogen propulsion, aiming to develop a system that can power regional aircraft and, eventually, larger commercial jets.

- ZeroAvia’s HyFlyer II has already demonstrated hydrogen-electric flight in six-seat aircraft and is working toward certification for 19-seat planes, with commercial flights targeted for the mid-2020s.

These projects are not just about technology—they’re about jobs, supply chains, and national competitiveness. The UK aims to become a global leader in green aviation, creating thousands of high-value engineering and manufacturing jobs in the process. This includes not only the design and build of aircraft and fuel cells, but also pilot training, maintenance, hydrogen production, and airport infrastructure.

The pace of progress depends on many factors—technological breakthroughs, regulatory approval, investment, and public acceptance. But the direction is clear: the era of zero-emission flight is starting, and the UK is determined to be at the forefront.

Challenges and Realistic Expectations

While the technology is advancing rapidly, it’s important to be realistic about timelines and limitations:

- eVTOLs (flying taxis): Likely to be the first hydrogen aircraft in commercial service, possibly by the late 2020s. These are small, short-range vehicles for urban mobility.

- Regional aircraft: Larger, fixed-wing planes for city-to-city routes could follow in the 2030s, depending on the speed of technological progress and infrastructure development.

- Long-haul commercial jets: The most challenging category. Most aviation experts agree that battery-electric or hydrogen fuel cell propulsion for widebody jets is many years away, if feasible at all. Hybrid systems using SAF or liquid hydrogen may be a stepping stone.

This phased approach is practical and reflects the real-world complexity of replacing a technology refined over a century with something entirely new.

Careers and Opportunities

The transition to zero-emission aviation is creating a wave of new career opportunities—across research, engineering, manufacturing, maintenance, policy, and infrastructure. Some key roles include:

- Electrochemical and fuel cell engineers (designing, testing, and improving fuel cell systems)

- Aerospace and avionics engineers (integrating new propulsion systems into aircraft)

- Data scientists and instrumentation specialists (developing advanced monitoring and diagnostics)

- Hydrogen infrastructure specialists (designing and building hydrogen production, storage, and distribution networks for airports)

- Pilots and maintenance technicians (training to operate and service new types of aircraft)

- Policy and regulatory experts (helping set standards and safety rules for hydrogen aviation)

Coventry University and its partners are actively working on education and training programs to prepare the next generation for these roles, ensuring that the UK has the skilled workforce needed to lead in green aviation.

Carbon Emissions From Tech Sector Rise With AI Expansion, Report Warns

FAQs About Carbon-Zero Aircraft

What is a carbon-zero aircraft?

A carbon-zero aircraft produces no net carbon dioxide emissions during flight. This is most likely achieved with hydrogen fuel cells or all-electric systems powered by renewable energy.

How does a hydrogen fuel cell work in an airplane?

A hydrogen fuel cell combines hydrogen (stored onboard) with oxygen (from the air) to produce electricity, which powers electric motors. The only byproduct is water vapor.

Why can’t we use batteries for all airplanes?

Batteries are improving but are still much heavier than hydrogen for the same amount of energy. This makes them impractical for anything beyond small, short-range aircraft.

When will carbon-zero flights be available?

eVTOLs (flying taxis) could enter service by the late 2020s. Regional aircraft might follow in the 2030s. Larger commercial jets face greater technical hurdles and are not expected for decades, if at all.

Are hydrogen planes safe?

Yes, hydrogen can be handled safely in aviation, with robust engineering, leak detection, and multiple safety systems. Coventry’s research is specifically focused on making fuel cells even more reliable and safe for flight.

How does this research create jobs?

Projects like HEIGHTS, AFCAD, and H2GEAR support high-value jobs in engineering, manufacturing, maintenance, and infrastructure. The UK aims to become a global hub for green aviation technology.