Breakthrough Electrodes Could Make Green Hydrogen Cheaper and Last Longer: In the global push toward sustainable energy, green hydrogen has emerged as a promising solution. Produced through water electrolysis powered by renewable energy sources, green hydrogen offers a clean alternative to fossil fuels.

However, challenges related to cost and durability have hindered its widespread adoption. Recent advancements in electrode technology are poised to address these issues, making green hydrogen production more efficient, affordable, and durable.

Breakthrough Electrodes Could Make Green Hydrogen Cheaper and Last Longer

| Aspect | Details |

|---|---|

| Innovations | Development of advanced electrodes enhancing efficiency and durability |

| Materials Used | Nickel-carbon nitride, cobalt-based heterostructures, ruthenium-infused carbon fabrics |

| Performance Metrics | Achieved low overpotentials (as low as 11.9 mV) and high durability (over 10,000 cycles) |

| Cost Implications | Reduction in reliance on expensive materials like platinum, lowering overall costs |

| Scalability | Techniques compatible with existing manufacturing processes, facilitating large-scale adoption |

| Environmental Impact | Supports cleaner hydrogen production, reducing carbon footprint |

| Further Reading | Technical University of Denmark – Hydrogen Research |

The development of advanced electrode materials marks a significant step forward in making green hydrogen a viable and sustainable energy source. By enhancing efficiency, reducing costs, and improving durability, these innovations address key challenges in the hydrogen economy. As research progresses and these technologies move toward commercialization, they hold the promise of facilitating a cleaner, more sustainable energy future.

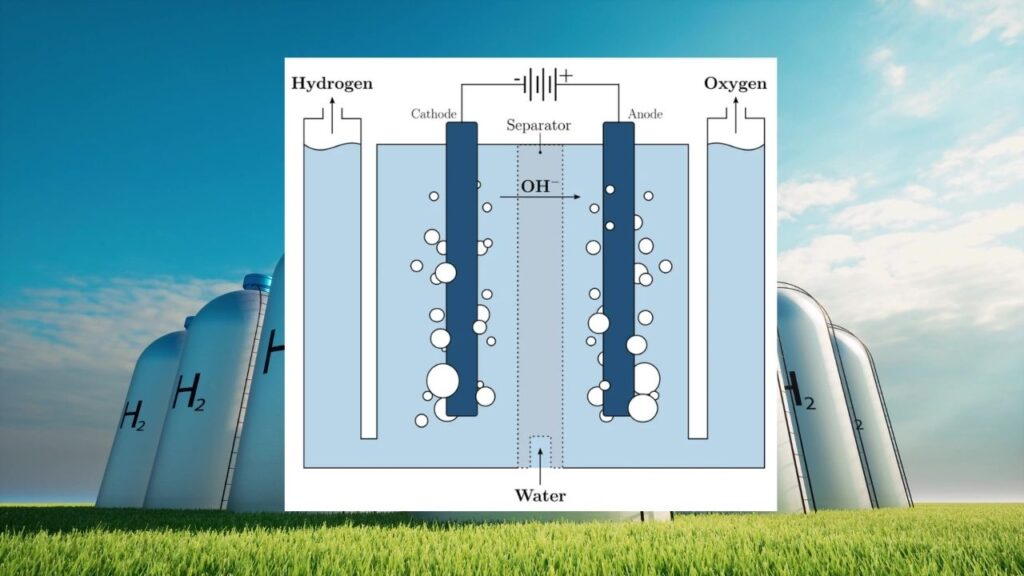

Understanding Green Hydrogen and Electrolysis

Green hydrogen is produced by splitting water (H₂O) into hydrogen (H₂) and oxygen (O₂) using electricity derived from renewable sources. This process, known as electrolysis, relies heavily on the performance of electrodes, which facilitate the necessary chemical reactions. The efficiency, cost, and longevity of these electrodes directly impact the viability of green hydrogen as a sustainable energy source.

Recent Advancements in Electrode Technology

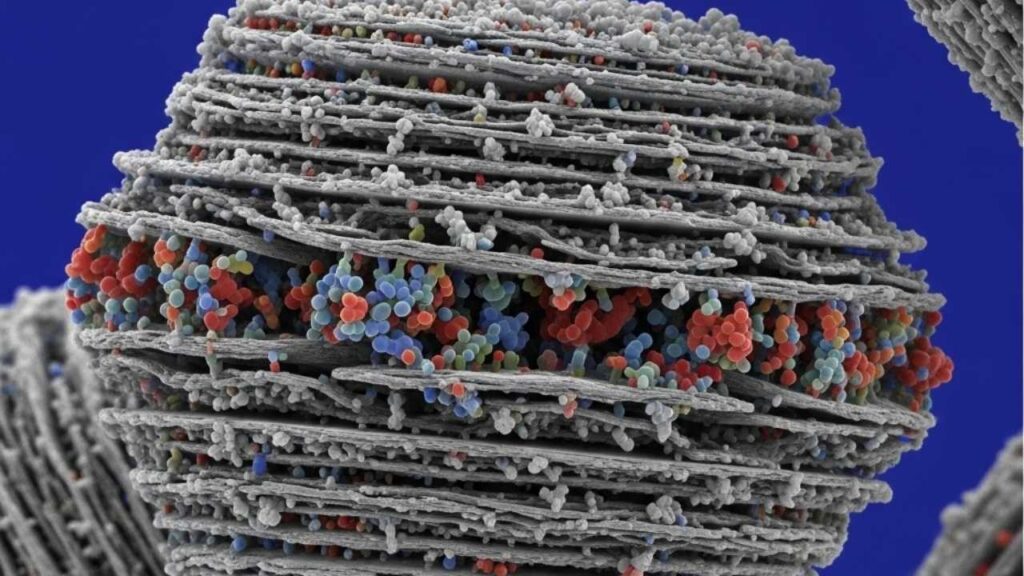

1. Nickel-Carbon Nitride Coated Electrodes

Researchers have developed a three-dimensional electrode structure composed of pyrolytic carbon coated with nickel and carbon nitride. This design significantly enhances the electrochemical active surface area, leading to improved catalytic activity and corrosion resistance in both acidic and alkaline conditions. The electrode demonstrated excellent durability over 2,000 cycles without significant performance decay, offering a scalable and cost-effective solution for sustainable hydrogen production.

2. Cobalt-Based Metallic Heterostructures

A novel cobalt-based metallic heterostructure (Co₃Mo₃N/Co₄N/Co) has been designed for alkaline water electrolysis. This structure enhances water adsorption and dissociation, resulting in efficient hydrogen production. The electrolyzer using this catalyst achieved a low cell voltage of 1.58 V at 10 mA cm⁻² and maintained approximately 100% retention over 100 hours at 200 mA cm⁻², outperforming commercial Pt/C || RuO₂ electrolyzers.

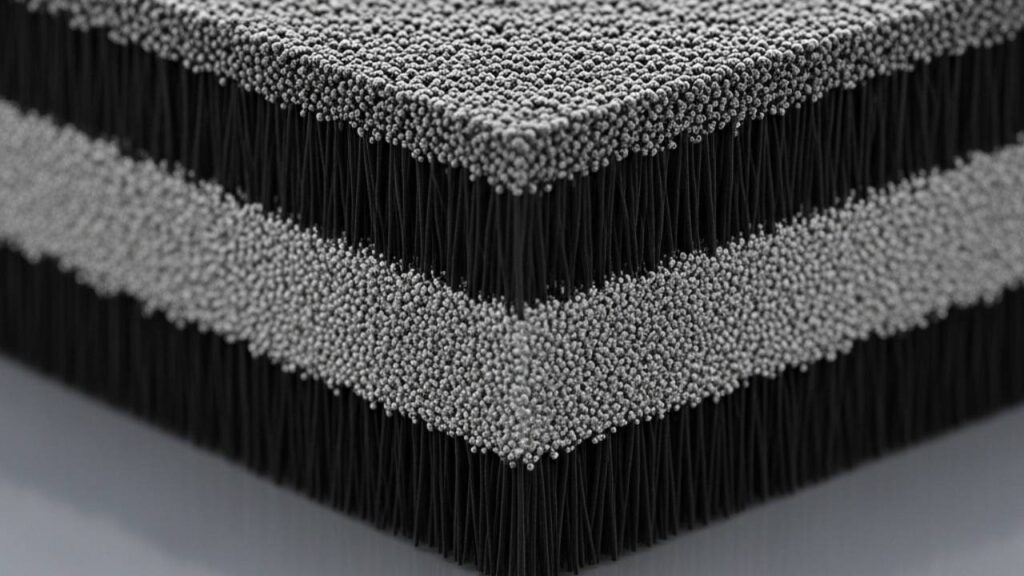

3. Ruthenium-Infused Carbon Fabric Electrodes

Innovative carbon fabric electrodes embedded with ruthenium have been developed, offering remarkable stability and efficiency. By integrating ruthenium into the polymer precursor fiber early in manufacturing, these electrodes demonstrate low overvoltage and reduced costs. They exhibit a lifespan 100 times longer than conventional electrodes, paving the way for large-scale, low-cost green hydrogen production.

Implications for the Energy Sector

The advancements in electrode technology have significant implications:

- Cost Reduction: Utilizing abundant and less expensive materials like nickel and cobalt reduces dependency on costly elements like platinum.

- Enhanced Durability: Improved electrode longevity decreases maintenance and replacement costs.

- Scalability: Compatibility with existing manufacturing processes facilitates large-scale adoption.

- Environmental Benefits: More efficient and cleaner hydrogen production contributes to reducing greenhouse gas emissions.pubs.rsc.org

Think It Was a Black Hole? Scientists Say It Might Have Been Something Even Stranger

Physicists Create One of the Most Neutron-Deficient Isotopes Ever Observed in the Lab

Attosecond ‘Clock’ Measures Electron Tunneling Time With Unmatched Precision

FAQs About Breakthrough Electrodes Could Make Green Hydrogen Cheaper and Last Longer

What is the significance of electrode materials in green hydrogen production?

Electrode materials directly impact the efficiency, cost, and durability of the electrolysis process. Advanced materials like nickel-carbon nitride and cobalt-based heterostructures enhance performance and reduce costs.

How do these advancements affect the cost of green hydrogen?

By reducing reliance on expensive materials and improving efficiency, these technologies lower the overall cost of green hydrogen production, making it more competitive with fossil fuels.

Are these technologies ready for commercial deployment?

While some are still in the research or pilot stages, the compatibility with existing manufacturing processes suggests a promising path toward commercialization.

How do these innovations contribute to environmental sustainability?

Improved electrode technologies enable more efficient and cleaner hydrogen production, reducing the carbon footprint associated with energy generation.