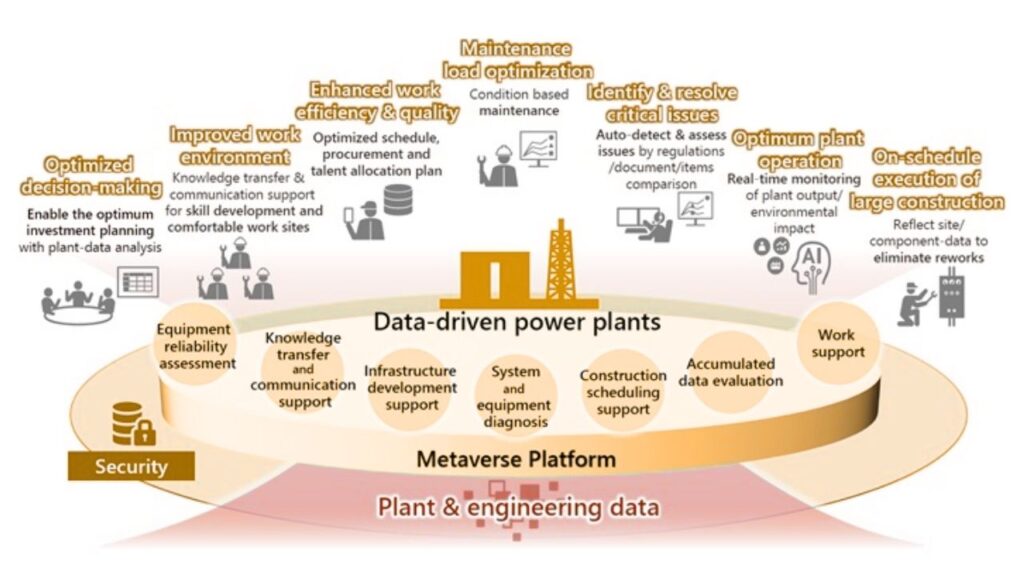

Hitachi Develops ‘Metaverse Platform’ for Nuclear Power Plants—this headline isn’t just about new technology; it signals a fundamental shift in how the world’s most advanced energy systems are managed, maintained, and made safer for everyone. Imagine a world where engineers, plant operators, and global experts can step into a virtual version of a nuclear power plant, collaborate in real time, and solve complex problems together—without ever leaving their offices. That’s the powerful vision behind Hitachi’s new metaverse platform, officially introduced in July 2025.

In this article, we’ll break down what this platform is, why it’s so important, and how it’s set to change the future of nuclear energy. Whether you’re a student, a seasoned energy professional, or simply curious about how technology is making our world more sustainable, you’ll find clear explanations, practical advice, and valuable insights here.

Hitachi Develops Metaverse Platform for Nuclear Power Plants

| Feature/Topic | Details |

|---|---|

| Launch Date | July 2025 |

| Core Technology | High-precision digital twin, metaverse, AI, data analytics |

| Main Purpose | Streamline nuclear plant operations, enhance safety, knowledge transfer, reduce on-site work |

| Industry Challenge Addressed | Labor shortages, skills transfer, operational efficiency, plant safety |

| Global Nuclear Growth | Nuclear output expected to grow steadily as countries pursue carbon neutrality |

| Carbon Neutrality Target | Supports Japan’s and global efforts for carbon neutrality by 2050 |

| Professional Impact | Enables remote collaboration, reduces risk, improves asset management, supports workforce upskilling |

| Official Website | Hitachi Energy |

Hitachi’s Metaverse Platform for Nuclear Power Plants is more than a technological breakthrough—it’s a practical solution to some of the toughest challenges facing the energy industry. By combining digital twins, AI, and immersive collaboration tools, Hitachi is making nuclear power safer, more efficient, and more accessible for the next generation. As the world moves toward carbon neutrality, innovations like this will be essential for delivering clean, reliable energy.

What Is the Metaverse Platform for Nuclear Power Plants?

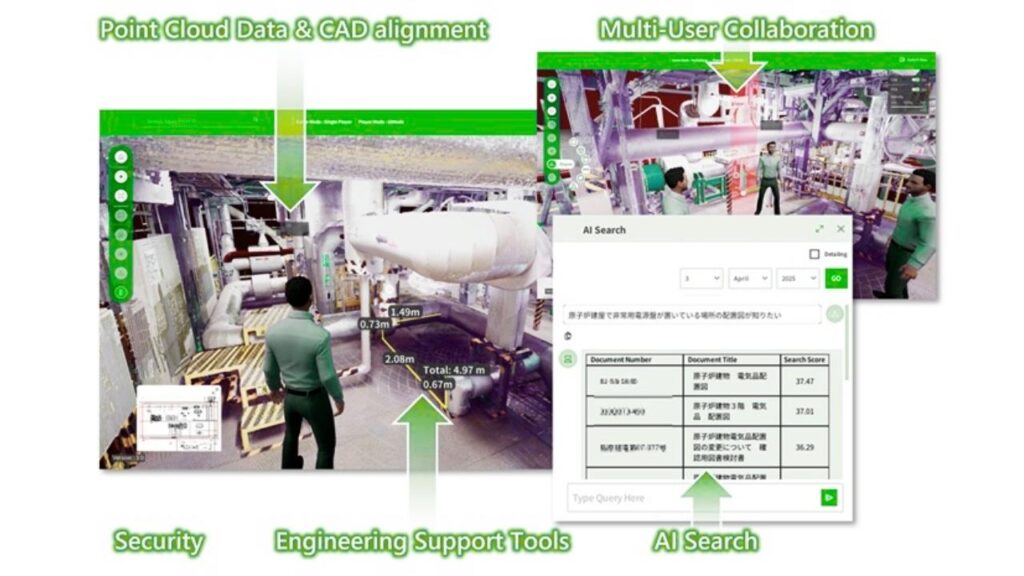

Hitachi’s Metaverse Platform is a sophisticated digital environment that recreates nuclear power plants in 3D with remarkable accuracy. Using advanced laser scanning (point clouds) and 3D CAD modeling, the platform generates a “digital twin”—a virtual replica of the real plant.

This digital twin is hosted within the metaverse, a shared online space where users can interact, collaborate, and explore the plant together as avatars.

But the platform is much more than a virtual tour. It’s a powerful suite of tools and features designed to solve real-world challenges:

- AI-powered analytics to monitor plant equipment, predict maintenance needs, and optimize operations.

- Collaboration tools so engineers, contractors, and operators can work together seamlessly from anywhere in the world.

- Immersive training simulations that allow new workers to learn in a safe, virtual environment.

- Remote inspections and design reviews that minimize the need for on-site visits, saving time and reducing exposure to hazards.

Why Is This Platform Important? Understanding the Industry’s Challenges

Nuclear power is a cornerstone of the world’s clean energy future. It produces vast amounts of electricity with zero carbon emissions, making it essential for countries aiming to achieve carbon neutrality. However, managing a nuclear power plant is one of the most complex and demanding jobs in the energy sector.

Here are some of the major challenges the industry faces:

1. Aging Workforce and Skills Shortage

Many experienced nuclear engineers and technicians are nearing retirement age. At the same time, fewer young professionals are entering the field. This creates a “skills gap” that makes it difficult to maintain high safety and operational standards.

2. Safety and Reliability Demands

Nuclear plants must operate safely and reliably for decades. This requires constant monitoring, rigorous inspections, and strict adherence to regulations. Any mistake can have serious consequences.

3. Complex Upgrades and Maintenance

Modernizing a nuclear plant or installing new equipment is a highly complex process. It often involves multiple teams, detailed planning, and precise execution—sometimes in areas that are difficult or dangerous to access.

4. Need for Efficient Knowledge Transfer

As experienced workers retire, their knowledge and expertise must be passed on to new generations. Traditional training methods can be slow and less effective, especially for hands-on skills.

5. Pressure to Support Carbon Neutrality

Countries around the world are setting ambitious carbon neutrality goals, and nuclear power is a key part of the solution. Plants must operate more efficiently and adapt quickly to changing energy demands.

How Does the Metaverse Platform Work? Step-by-Step Breakdown

Step 1: Creating the Digital Twin

- Laser Scanning: Specialized equipment scans every part of the plant, generating a detailed “point cloud” map.

- 3D Modeling: Engineers use computer-aided design (CAD) software to build a virtual model from the scan data.

- Data Integration: The digital twin is linked to real-time data from plant sensors, maintenance records, and operational systems.

Step 2: Entering the Metaverse

- User Access: Authorized personnel log in from their computers or virtual reality (VR) headsets.

- Avatars and Interaction: Users appear as avatars, allowing them to “walk” through the plant, interact with equipment, and collaborate with colleagues in real time.

Step 3: Leveraging AI and Data Analytics

- Predictive Maintenance: AI analyzes equipment data to identify issues before they become problems, reducing unplanned downtime.

- Smart Scheduling: The system recommends optimal times for maintenance and upgrades, improving efficiency and minimizing disruptions.

Step 4: Training and Knowledge Transfer

- Immersive Training: New workers can practice complex procedures in the virtual plant, learning from digital mentors and recorded sessions.

- Remote Support: Experts can guide teams through difficult tasks remotely, providing real-time advice and oversight.

Step 5: Remote Inspections and Design Reviews

- Virtual Walkthroughs: Engineers can review plant layouts, test new equipment routes, and verify designs—all within the digital twin.

- Reduced Site Visits: Many inspections and reviews that once required physical presence can now be completed virtually, saving time and reducing risk.

Practical Benefits: Real-World Scenarios

Let’s look at how Hitachi’s platform can improve daily operations at a nuclear plant:

Example 1: Installing New Equipment

A plant needs to install a new safety valve in a tight, hard-to-reach area. Traditionally, this would require multiple site visits, physical measurements, and coordination between several teams. With the metaverse platform:

- The design team creates a virtual model of the new valve and its installation route.

- Engineers from different companies join the metaverse, discussing the plan in real time.

- AI checks for potential conflicts with existing equipment or structures.

- The team conducts a virtual “dry run,” identifying and solving problems before any real work begins.

- The actual installation is smoother, safer, and faster.

Example 2: Training New Operators

A new operator needs to learn how to perform a critical maintenance procedure. Instead of waiting for a real-world opportunity, they:

- Enter the metaverse and practice the procedure in a realistic, risk-free environment.

- Receive feedback from digital mentors and experienced staff.

- Build confidence and competence before ever touching real equipment.

Example 3: Responding to Emergencies

In the unlikely event of an emergency, the platform allows teams to:

- Simulate emergency scenarios and practice coordinated responses.

- Identify weaknesses in procedures and make improvements before a real event occurs.

The Broader Impact: Why This Is a Game Changer

Addressing Workforce Challenges

By capturing and sharing expert knowledge in the metaverse, Hitachi’s platform helps bridge the skills gap. New workers can learn directly from digital records and virtual mentors, ensuring that critical expertise isn’t lost as older workers retire.

Enhancing Safety and Efficiency

Remote inspections, predictive maintenance, and virtual training all contribute to a safer, more efficient workplace. Fewer people need to enter hazardous areas, and problems can be identified and solved before they escalate.

Supporting Global Carbon Neutrality Goals

Reliable, efficient nuclear power plants are essential for reducing carbon emissions and meeting climate targets. By streamlining operations and enabling faster upgrades, the platform helps plants deliver more clean energy to the grid.

Driving Innovation Across the Industry

Hitachi’s metaverse platform sets a new standard for what’s possible in the energy sector. Its success could inspire similar innovations in other industries, from oil and gas to manufacturing and beyond.

FAQs About Hitachi Develops Metaverse Platform for Nuclear Power Plants

What is a digital twin?

A digital twin is a virtual replica of a real-world object or system. In this case, it’s a 3D model of a nuclear power plant that updates with real-time data.

How does the metaverse platform improve safety?

By enabling remote inspections and training, the platform reduces the need for personnel to enter hazardous areas. It also allows for better planning and risk assessment.

Who can access the platform?

Access is restricted to authorized personnel such as plant operators, engineers, and approved contractors to ensure security and safety.

Is special equipment required to use the platform?

No special hardware is needed. Users can access the platform from standard computers, though VR headsets can enhance the experience.

How does this technology help with carbon neutrality?

By making nuclear plants safer, more reliable, and more efficient, the platform supports the delivery of clean, carbon-free electricity.

What are the next steps for this technology?

Hitachi plans to expand the platform’s features, including more advanced AI tools, integration with other energy systems, and broader adoption across the energy sector.