How Advanced Materials Are Making Flexible Electronics a Reality: Flexible electronics are transforming the way we think about technology, making it possible to bend, stretch, and fold devices without losing functionality. But how are advanced materials enabling this revolution? In this article, we’ll explore the remarkable role that cutting-edge materials play in turning flexible electronics from a futuristic idea into a practical, everyday reality. Whether you’re a curious beginner or a seasoned professional, this detailed guide will break down complex concepts into clear, understandable steps — complete with real-world examples and expert insights.

Flexible electronics refer to electronic devices built on materials that allow them to bend or flex while still operating perfectly. Imagine a smartphone screen that folds in half without cracking or wearable sensors that conform comfortably to your skin. These innovations rely heavily on advanced materials—special substances engineered to combine flexibility with superior electrical and mechanical properties.

Today, materials like graphene, two-dimensional (2D) semiconductors, and flexible polymers are paving the way for exciting new applications in healthcare, energy, consumer electronics, and more. But understanding how these materials work and how they are manufactured is key to appreciating the technology’s full potential.

Table of Contents

How Advanced Materials Are Making Flexible Electronics a Reality

| Topic | Details |

|---|---|

| Advanced Materials Used | Graphene, Transition Metal Dichalcogenides (TMDs), Phosphorene, Flexible Polymers |

| Applications | Wearable health sensors, electronic skin, flexible displays, solar fabric, bendable batteries |

| Market Size & Growth | Global flexible electronics market expected to reach $70 billion by 2027 |

| Key Challenges | Material stability, scalable manufacturing, durability under stress |

| Official Resource | Flexible Electronics at U.S. Department of Energy |

Advanced materials are the cornerstone of the flexible electronics revolution, enabling devices that are lightweight, bendable, and multifunctional. From graphene’s unmatched conductivity to innovative fabrication techniques, the technology is progressing rapidly, unlocking exciting new possibilities across industries. While challenges around durability and manufacturing remain, ongoing research and development are steadily overcoming these hurdles, bringing flexible electronics ever closer to everyday use.

What Are Advanced Materials in Flexible Electronics?

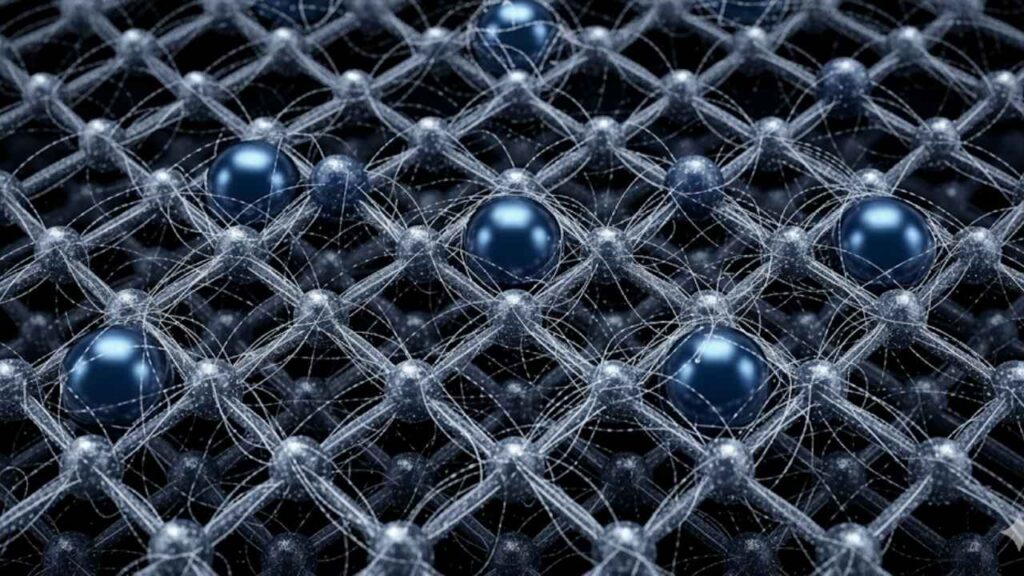

At the heart of flexible electronics are materials designed to maintain high electrical performance while being bendable or stretchable. Traditional electronic materials like silicon are brittle and easily damaged by bending. Advanced materials, however, combine flexibility, conductivity, and durability — enabling new device architectures.

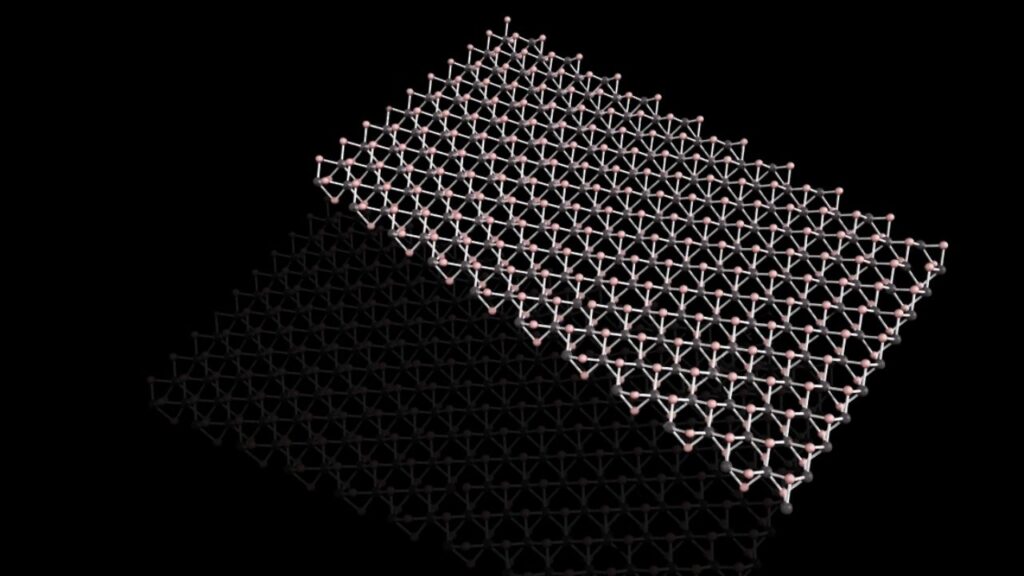

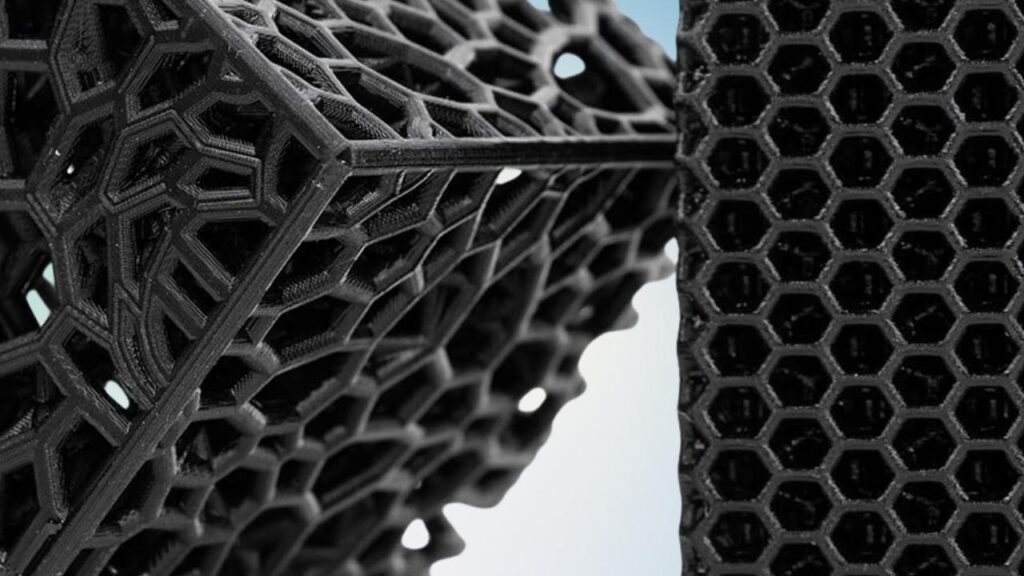

Graphene: The Wonder Material

Graphene is a single layer of carbon atoms arranged in a honeycomb lattice. It is incredibly strong, highly conductive, and extremely thin, making it an ideal candidate for flexible circuits and sensors. Researchers use graphene to create ultra-thin electrodes that can bend without losing their electrical properties.

Transition Metal Dichalcogenides (TMDs)

TMDs such as molybdenum disulfide (MoS₂) and tungsten diselenide (WSe₂) are 2D semiconductors with tunable electrical properties. Unlike graphene, which is a conductor, TMDs can act as semiconductors, making them useful in flexible transistors and photodetectors.

Flexible Polymers and Substrates

Flexible plastics like polyethylene terephthalate (PET) or polyimide serve as substrates—the base layers onto which advanced materials are deposited. These substrates provide mechanical support and allow the devices to bend and stretch while maintaining their shape.

How Are Flexible Electronics Made?

Creating flexible electronics involves combining advanced materials with innovative fabrication techniques. Here’s a step-by-step look at the process:

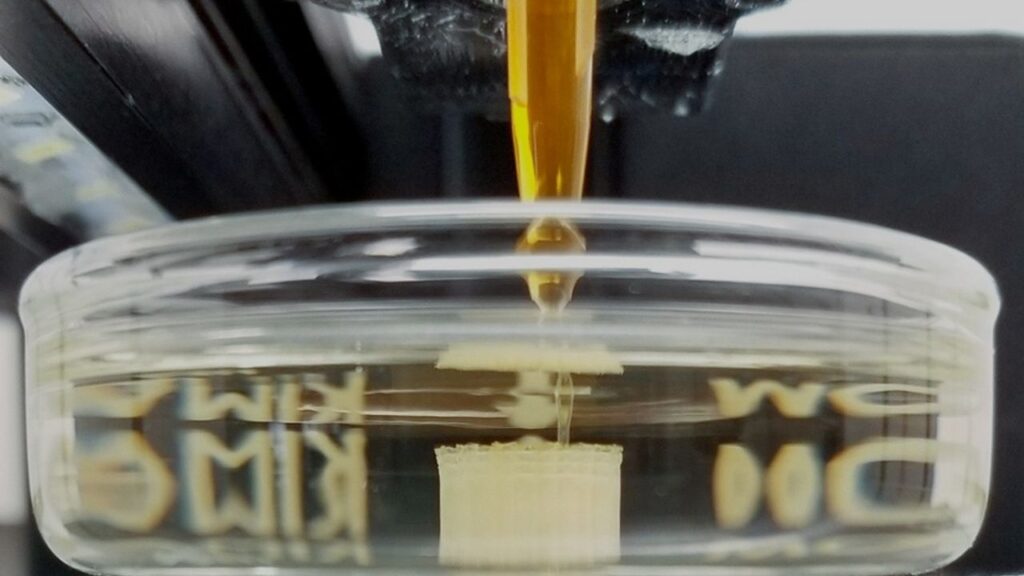

1. Material Synthesis

The first step is producing high-quality sheets or films of advanced materials. Techniques include chemical vapor deposition (CVD) for graphene and mechanical exfoliation for TMDs. The goal is to produce uniform, defect-free materials suitable for device fabrication.

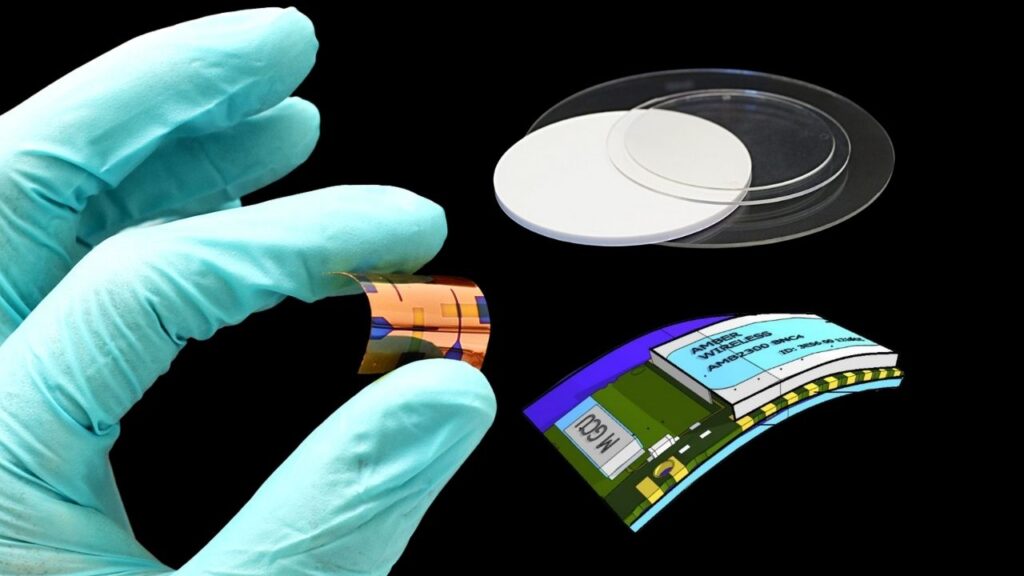

2. Transfer to Flexible Substrates

Once synthesized, these materials are carefully transferred onto flexible substrates. This step uses dry-transfer techniques or roll-to-roll processing to avoid damaging the delicate films.

3. Patterning and Printing

Microprinting and photolithography are used to create the intricate circuit patterns on the flexible substrates. These processes must be optimized to work on bendable surfaces without cracking or delaminating.

4. Device Assembly and Testing

Finally, the flexible components are assembled into devices such as sensors, displays, or energy harvesters. Rigorous testing ensures the devices maintain performance after repeated bending and stretching.

Practical Applications of Flexible Electronics

Advanced materials are opening doors to a wide range of practical applications:

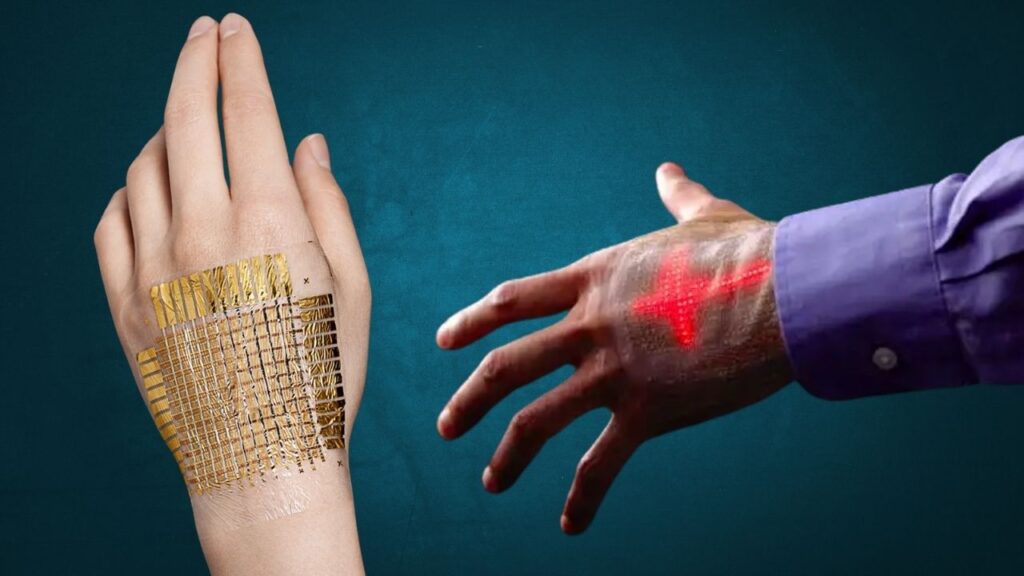

Wearable Health Sensors

Flexible biosensors monitor heart rate, blood oxygen, and other vital signs with better comfort and accuracy. These sensors conform to the skin’s surface, providing continuous real-time data without the bulk of traditional devices.

Electronic Skin (E-Skin)

Inspired by human skin, e-skin integrates pressure, temperature, and motion sensors on a flexible surface. This technology is pivotal for prosthetics, robotics, and human-machine interfaces.

Flexible Displays and Smartphones

Foldable smartphones and rollable displays rely on flexible OLED and micro-LED technologies combined with advanced materials, enabling devices that can be compacted or expanded at will.

Energy Harvesting and Storage

Flexible solar cells embedded in fabrics and flexible batteries enable self-powered wearable electronics, reducing the need for bulky external chargers.

Challenges to Overcome

Despite the progress, several hurdles remain:

- Material Stability: Flexible materials must withstand bending cycles, temperature changes, and environmental exposure without degrading.

- Manufacturing Scale: Producing these advanced materials cost-effectively at large scale remains challenging.

- Durability: Long-term mechanical and electrical stability under real-world conditions is still being improved.

Nanotechnology Unveiled: Tiny Innovations That Could Solve Huge Problems

Quantum Leap: Understanding the Impact of Quantum Computing on Cybersecurity

Inside the Lab: Breakthroughs in Organic Solar Cells Could Change Energy Forever

FAQs About How Advanced Materials Are Making Flexible Electronics a Reality

What makes a material “advanced” for flexible electronics?

Advanced materials possess unique mechanical and electrical properties, such as high flexibility combined with excellent conductivity or semiconducting behavior, that allow electronic devices to function while bent or stretched.

Are flexible electronics durable?

Yes, modern flexible electronics are designed to endure thousands of bending cycles and everyday use. However, ongoing research aims to improve long-term durability further.

How soon will flexible electronics become mainstream?

Flexible electronics are already present in niche markets like wearables and foldable phones. Industry forecasts predict wider adoption over the next 5 to 10 years as costs decrease and technology matures.