Intelligent Sensors Reduce Energy Use in Industrial Settings: In today’s world, where energy efficiency and sustainability are top priorities, industries are turning to smart technologies for solutions. One of the most effective innovations in this space is the use of intelligent sensors. These smart devices are transforming how factories, warehouses, and manufacturing plants manage their energy usage—saving money, reducing waste, and even helping the planet.

This article explores how intelligent sensors reduce energy use in industrial settings, using real-world examples, expert insights, and actionable strategies. Whether you’re managing an industrial site or just curious about green tech, you’ll find this guide clear, practical, and packed with value.

Intelligent Sensors Reduce Energy Use in Industrial Settings

| Feature/Topic | Details |

|---|---|

| Main Benefit | Up to 40% energy savings in lighting and HVAC systems |

| Process Optimization | Real-time monitoring cuts gas losses and improves system stability |

| Predictive Maintenance | Reduces downtime by up to 22% |

| Smart Grid Impact | Transmission/distribution loss cut by 10–12% |

| Global Adoption | Used by Amazon, Disney, and steel mills worldwide |

| Best For | Factories, logistics, cold storage, power plants |

| Official Resource | U.S. Department of Energy |

Intelligent sensors reduce energy use in industrial settings by enabling real-time data monitoring, automating responses, and improving overall efficiency. From predictive maintenance to process optimization, the benefits are tangible and measurable. With climate change, rising energy costs, and sustainability becoming non-negotiables, smart sensor tech offers a path forward for industrial facilities that want to thrive.

What Are Intelligent Sensors?

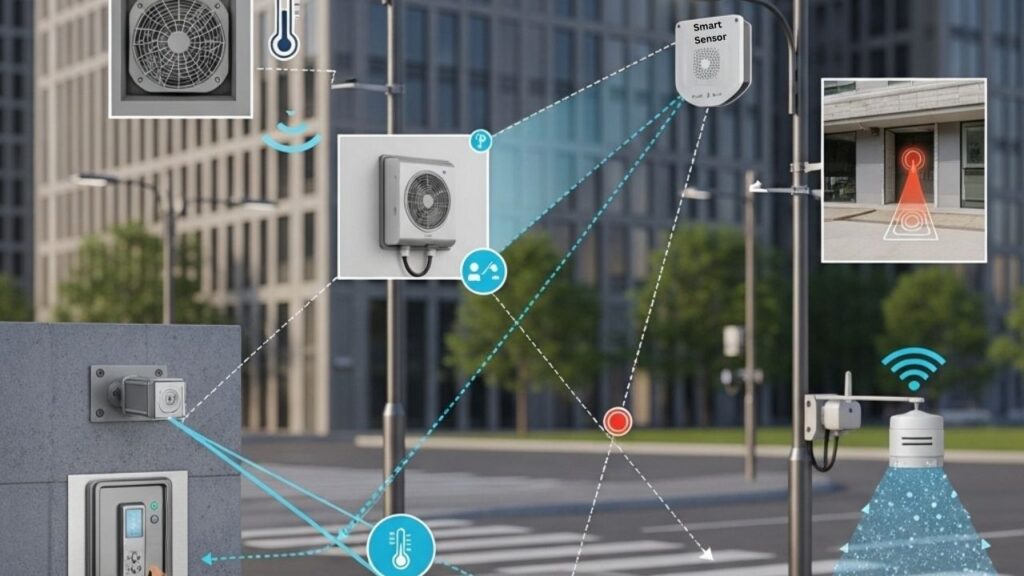

Intelligent sensors are devices that not only detect changes (like motion, temperature, or pressure) but also process that data in real time to trigger smart actions. For instance, a smart temperature sensor can adjust HVAC systems based on occupancy or external weather—without human intervention.

These sensors form the foundation of Industrial Internet of Things (IIoT) ecosystems. They work together with cloud platforms and machine learning algorithms to create a feedback loop, ensuring energy is only used when and where it’s needed.

How Intelligent Sensors Reduce Industrial Energy Use

1. Optimizing Lighting and HVAC Systems

In large industrial buildings, lighting and climate control are major energy consumers. Sensors monitor occupancy, daylight, and temperature, allowing systems to:

- Dim or shut off lights when areas are unoccupied.

- Adjust HVAC output based on room usage and external weather.

- Integrate with building management systems (BMS) for automated responses.

Occupancy sensors can cut lighting energy use by 30–60%, and smart thermostats can reduce heating and cooling energy by up to 30%.

Example:

In its fulfillment centers, Amazon implemented smart sensors to integrate temperature control and motion tracking, leading to 30% energy savings in 2023.

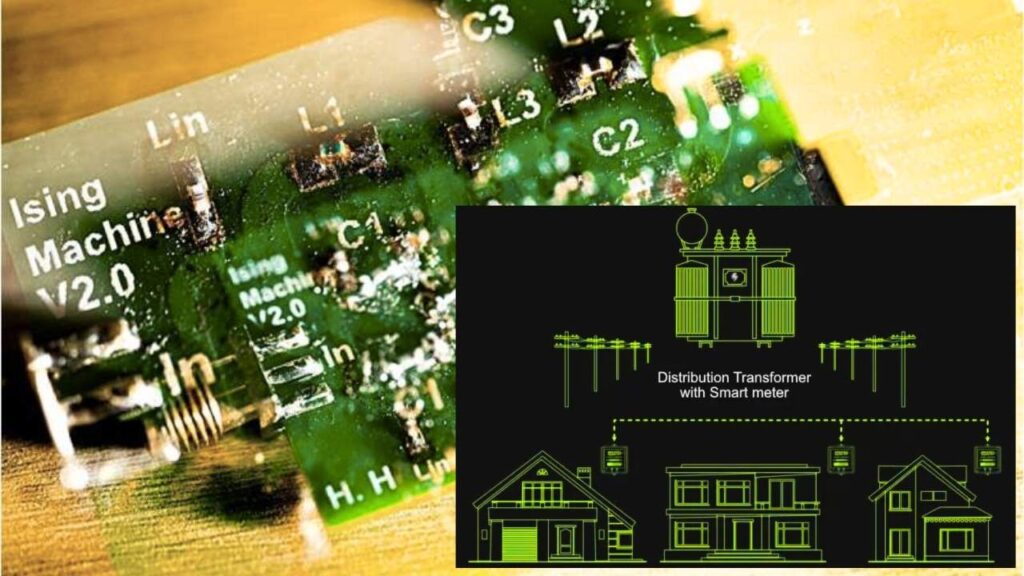

2. Reducing Energy Losses in Smart Grids

Smart grids powered by intelligent sensors are crucial for energy distribution optimization. Sensors track:

- Load patterns

- Voltage drops

- Power surges

By doing so, they prevent transmission losses, reduce downtime, and improve overall grid efficiency. Studies show smart grids can cut transmission and distribution losses by 10–12%.

Example:

A power plant in Germany equipped its distribution network with intelligent sensors and saw a 15% increase in energy delivery efficiency, with fewer system-wide failures.

3. Enabling Predictive Maintenance

Old equipment can waste energy due to wear and tear. Intelligent sensors can detect:

- Abnormal vibrations

- Temperature spikes

- Unusual sound frequencies

When anomalies are detected early, maintenance can be scheduled before a major failure—this prevents emergency shutdowns, energy spikes, and product loss.

A study revealed that predictive maintenance systems powered by sensor data reduced downtime by up to 22% and cut energy consumption by 18% in heavy industries.

4. Improving Industrial Process Efficiency

In production lines, sensors measure and adjust operations like:

- Chemical mixing

- Pressure levels

- Cooling processes

Example:

A steel mill in China implemented gas pressure sensors to reduce furnace gas loss from 5% to less than 1%. The network stability also jumped from 70% to 95%, saving millions of yuan annually.

In complex manufacturing setups, integrating power usage across all systems can improve energy management efficiency by up to 25%.

5. Monitoring Refrigeration and Cold Storage

Cold storage units, especially in food and pharmaceutical industries, consume a lot of energy. Smart sensors help by:

- Monitoring door openings

- Detecting air leaks

- Adjusting internal cooling

Example:

The bakery chain Greggs used intelligent monitoring to track energy consumption in refrigeration units. This saved the company 5% in annual utility costs and reduced spoilage from equipment failures.

Why It Matters

Aside from the obvious cost savings, intelligent sensors contribute to sustainability goals, regulatory compliance, and competitive advantage. By implementing these systems, companies can reduce their carbon footprint and qualify for energy-efficiency grants and tax incentives.

Many governments now mandate energy efficiency standards for industrial operations. Investing in sensor-based systems helps businesses stay ahead of regulations and attract ESG-focused investors.

Step-by-Step Guide: Getting Started With Intelligent Sensors

Step 1: Conduct an Energy Audit

- Identify key areas of energy consumption.

- Pinpoint outdated or inefficient systems.

Step 2: Choose Sensor Types Based on Use Case

- Motion sensors for lighting.

- Thermal sensors for HVAC.

- Vibration/ultrasound sensors for machinery.

Step 3: Integrate With Existing Systems

- Connect sensors to your BMS or SCADA platform.

- Ensure compatibility with cloud analytics platforms.

Step 4: Enable Real-Time Monitoring

- Use dashboards to visualize energy flow.

- Set up alerts for abnormal consumption.

Step 5: Run Pilot Tests

- Start in a small section of the facility.

- Measure performance and ROI before scaling.

Step 6: Scale and Automate

- Apply learnings to the entire facility.

- Automate responses to sensor feedback.

Battery-Free Physical AI: The New Frontier with picoRing and SenSync

Violent Solar Eruption Launches Coronal Mass Ejection Triggering Rare G4‑Level Geomagnetic Storm

Quantum Mechanics Centennial Spurs International Year Of Quantum Science & Technology

FAQs About Intelligent Sensors Reduce Energy Use in Industrial Settings

What types of sensors are most useful for industrial energy savings?

Answer: Commonly used sensors include motion detectors, temperature sensors, pressure gauges, gas analyzers, and vibration sensors—each tailored to specific energy systems.

How much do intelligent sensors cost to install?

Answer: Initial costs vary, but many industrial sensor systems start around $5,000 to $15,000 for small setups. Most companies recoup their investment within 6–18 months.

Are intelligent sensors difficult to maintain?

Answer: Not at all. Most require minimal upkeep and are built to withstand industrial environments. Software updates are usually handled remotely.

Do intelligent sensors work with older machines?

Answer: Yes. Many sensors are designed to retrofit older equipment without needing full system upgrades.