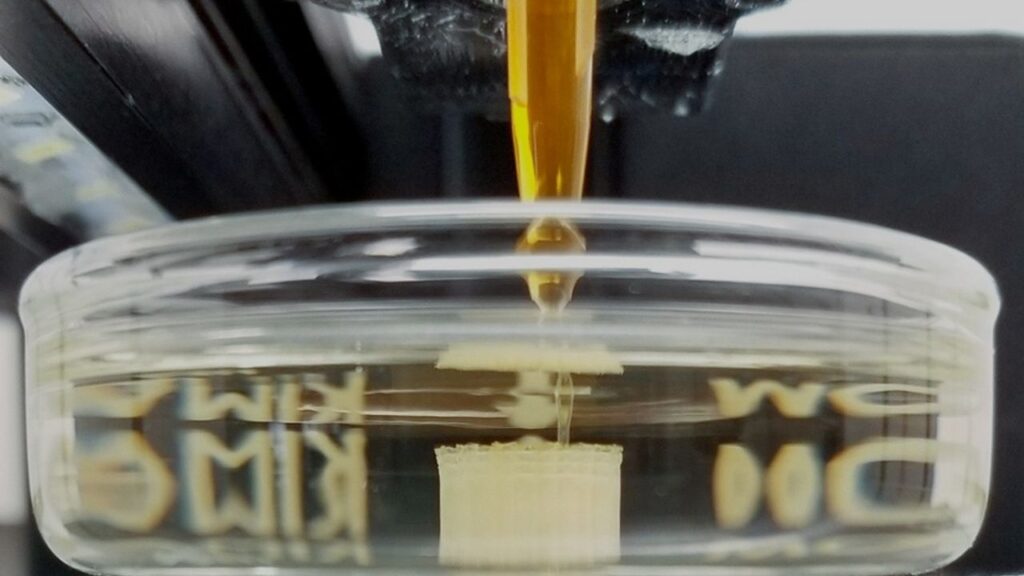

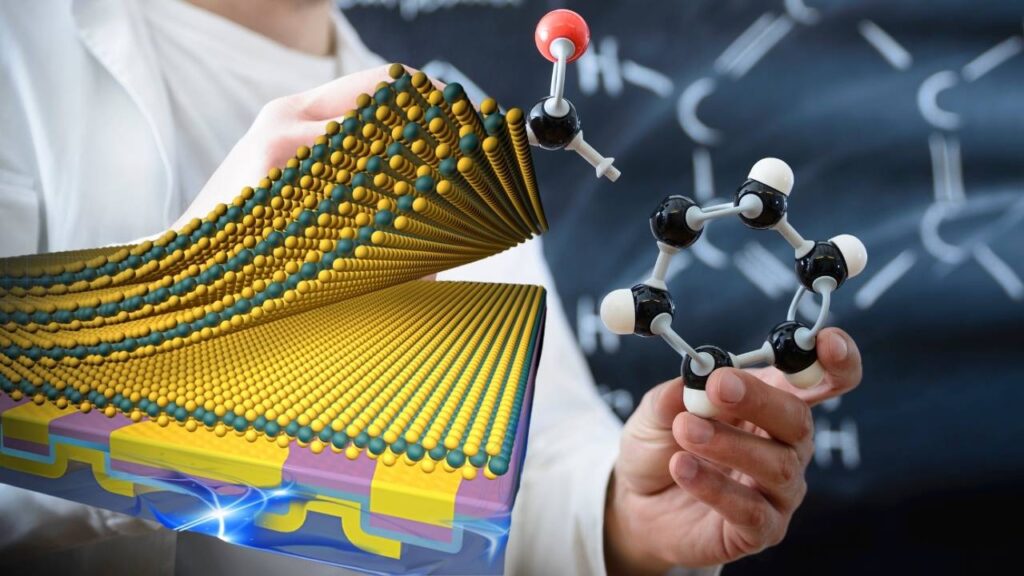

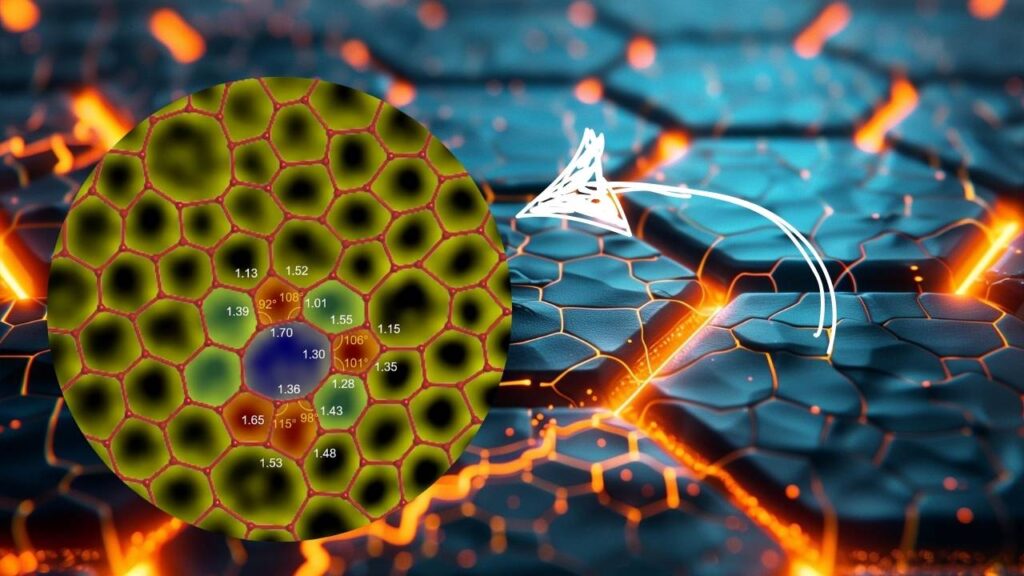

New 2D Material With Exceptional Adhesion Properties: In a groundbreaking scientific achievement, Rice University researchers have discovered a new 2D material with exceptional adhesion properties, potentially revolutionizing flexible electronics, aerospace coatings, and nanoengineering. This novel material, named monolayer amorphous carbon (MAC), offers a rare combination of high strength and remarkable toughness — a feat previously unmatched by other known 2D materials like graphene.

Developed in collaboration with the National University of Singapore (NUS), MAC represents a leap forward in materials science, especially for industries that demand ultra-thin yet resilient materials. What makes MAC truly special is its ability to resist cracking up to eight times better than graphene, according to a recent peer-reviewed study published in Matter.

Table of Contents

New 2D Material With Exceptional Adhesion Properties

| Feature | Details |

|---|---|

| Material Name | Monolayer Amorphous Carbon (MAC) |

| Discovered By | Rice University & National University of Singapore |

| Toughness | 8x more crack-resistant than graphene |

| Structure | Amorphous (non-crystalline), unlike graphene |

| Potential Uses | Flexible electronics, aerospace coatings, nanodevices |

| Published In | Matter Journal |

| Lead Researchers | Bongki Shin (Rice), Prof. Barbaros Özyilmaz (NUS) |

| Official News Source | Rice University Newsroom |

The discovery of monolayer amorphous carbon (MAC) by researchers at Rice University and the National University of Singapore marks a major milestone in the field of nanomaterials. With unmatched crack resistance, excellent adhesion, and flexibility, MAC has the potential to transform how we design everything from wearable tech to aerospace components.

As the technology matures, expect to see MAC stepping out of the lab and into real-world applications — making our devices tougher, smarter, and more reliable.

What Is Monolayer Amorphous Carbon (MAC)?

Let’s break it down simply.

Monolayer Amorphous Carbon is a single-atom-thick sheet of carbon atoms that lack a crystalline pattern. Unlike graphene, which is made of carbon atoms arranged neatly in a hexagonal honeycomb, MAC’s atoms are distributed randomly. This disordered structure helps disperse stress more evenly, making it significantly harder to crack.

Think of graphene like a tiled bathroom floor — neat and strong but vulnerable if a tile breaks. MAC, in contrast, is like a flexible rubber mat — less uniform, but highly resilient under pressure.

Why This Discovery Matters

For over a decade, graphene has been the poster child of nanomaterials. It’s incredibly strong, lightweight, and conductive. But there’s a catch — once a crack forms in graphene, it spreads easily, making it less durable in practical applications.

MAC changes that narrative. Here’s why it’s exciting:

- Superior Durability: MAC is 8 times tougher than graphene, meaning it can withstand far more mechanical stress without breaking.

- High Flexibility: It’s thin and bendable, perfect for wearable electronics and flexible displays.

- Improved Adhesion: Its surface sticks better to other materials, essential for coatings and protective films.

This makes MAC a top contender for replacing or complementing graphene in high-performance applications.

How MAC Was Developed

The journey to discovering MAC was as fascinating as the material itself.

Step 1: Synthesizing MAC in Singapore

The first stage of the research was carried out at the National University of Singapore, led by Professor Barbaros Özyilmaz. His team used a unique process to create the monolayer amorphous carbon sheet. This involved controlled deposition of carbon atoms onto a substrate at specific temperatures, ensuring no crystalline structures formed.

Step 2: Testing at Rice University

Once synthesized, the material was sent to Rice University, where graduate student Bongki Shin and other scientists performed rigorous mechanical testing. Using advanced microscopy and stress-testing equipment, they evaluated how MAC responded to force and pressure.

The results? MAC withstood crack propagation better than any known 2D material tested under similar conditions.

Real-World Applications

MAC’s properties make it incredibly versatile. Here’s how it could reshape industries:

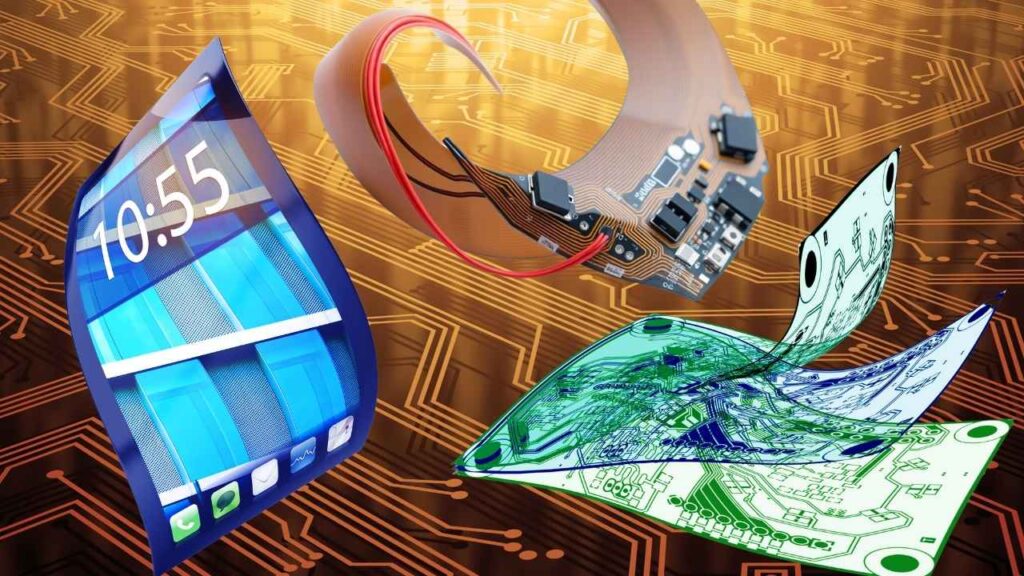

1. Flexible Electronics

Modern gadgets need materials that can bend without breaking. MAC’s thin, strong, and flexible nature makes it ideal for:

- Foldable smartphones

- Wearable fitness trackers

- Flexible medical sensors

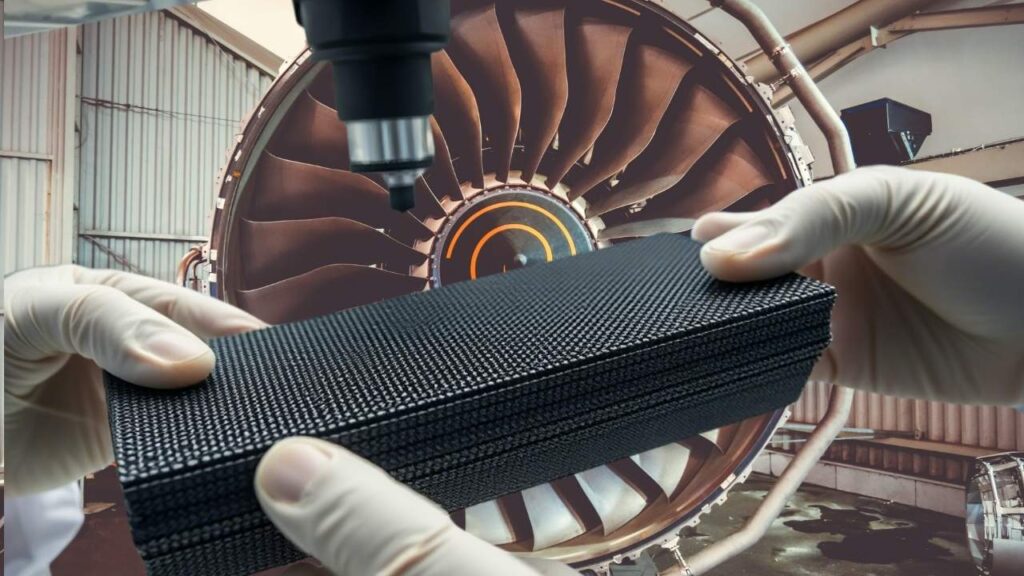

2. Aerospace Engineering

Aircraft and spacecraft components benefit from lightweight but tough coatings. MAC could provide protective layers that resist extreme mechanical stress and temperature changes.

3. Nanotechnology

MAC’s ultra-thin structure and adhesion properties make it suitable for:

- Protective nano-coatings

- Ultra-sensitive detectors and transistors

4. Energy Storage

Researchers believe MAC could also be integrated into battery electrodes and capacitors, enhancing durability and performance under repetitive cycles.

How MAC Compares to Graphene

| Property | Graphene | MAC |

|---|---|---|

| Structure | Crystalline | Amorphous |

| Crack Resistance | Moderate | 8x tougher |

| Electrical Conductivity | Very High | Moderate |

| Flexibility | High | Very High |

| Adhesion to Surfaces | Moderate | Exceptional |

While graphene still leads in electrical conductivity, MAC brings superior toughness and versatility to the table. The two materials may complement each other in future composite designs.

Challenges and Next Steps

Despite its promise, MAC isn’t quite ready for mass-market applications just yet.

- Scalability: Producing large, defect-free MAC sheets is still challenging.

- Integration: Engineers must figure out how to incorporate MAC into existing devices and manufacturing pipelines.

- Cost: As with all new materials, initial production costs are high.

However, Rice University and NUS researchers are optimistic. With growing interest and investment in nanomaterials, we may see MAC-based technologies within the next decade.

The Future of Displays: How MicroLEDs Are Set to Outshine OLED Technology

Light-Powered Computing: The Race to Build the First All-Optical Processor

Scientists Develop Self-Healing Materials for Electronics and Wearable Devices

FAQs About New 2D Material With Exceptional Adhesion Properties

What is monolayer amorphous carbon made of?

It’s made entirely of carbon atoms, just like graphene, but without an ordered structure.

How does MAC compare to graphene in electronics?

While MAC isn’t as electrically conductive as graphene, it excels in flexibility and toughness, making it better suited for mechanical and structural applications.

Can MAC be used in smartphones or wearable devices?

Yes. MAC’s flexibility and adhesion properties make it an excellent candidate for flexible displays and sensor coatings.

Is MAC commercially available?

Not yet. It’s still in the research and development phase, but companies and labs are actively exploring its potential.

Where can I read the official study?

You can find it in the journal Matter and on the Rice University official news page.