Imagine a material that doesn’t just stretch and bend like your muscles, but actually gets stronger the more you use it. This is now possible, thanks to a groundbreaking innovation in gel polymer technology. Scientists have developed a new kind of hydrogel—a water-rich, flexible material—that mimics the way real muscles work and even reinforces itself after being stressed. This discovery could change the future of robotics, medicine, and wearable technology.

In this article, you’ll discover how this muscle-like gel polymer works, why it’s so important, and what it means for the world of science and engineering. Whether you’re a curious student, a healthcare professional, or an engineer, you’ll find valuable insights and practical examples to help you understand this exciting new material.

Table of Contents

New Gel Polymer Mimics Muscle and Gains Strength With an Innovative Formula

| Feature/Stat | Details |

|---|---|

| Material Type | Self-strengthening, muscle-like hydrogel |

| How It Works | Polymer network breaks under stress, then reforms stronger bonds using monomers |

| Strength Gains | Up to 1.5x stronger, 23x stiffer, 86% increase in polymer weight after stress cycles |

| Key Technology | Double-network hydrogel with mechanophores and computationally designed force-sensitive bonds |

| Professional Use | Soft robotics, prosthetics, biomedical implants, regenerative medicine |

| Industry Value (2025) | US$ 2.1 billion, expected to double by 2032 |

| Official Resource | Hokkaido University News |

The new gel polymer that mimics muscle and grows stronger with use is a true game-changer. By combining clever chemistry with advanced computer modeling, scientists have created a material that adapts, heals, and improves itself—just like living tissue. This breakthrough opens the door to smarter robots, better medical implants, and more resilient wearable technology.

Whether you’re a student, a professional, or simply curious, this innovation is proof that nature-inspired materials can lead to real-world solutions that benefit everyone.

What Is a Muscle-Like Gel Polymer?

A muscle-like gel polymer is a special form of hydrogel—think of it as a soft, jelly-like material that’s mostly water but has a network of polymers holding it together. What makes this new gel so unique is its ability to sense when it’s being stretched or compressed and respond by getting stronger, much like how your muscles grow after exercise.

How Does It Work?

- The gel is built from two different polymer networks:

- One network is brittle and breaks under pressure.

- The other is soft and stretchy, keeping the gel intact.

- When you stretch or squeeze the gel, the brittle part breaks at a microscopic level. Instead of falling apart, this breakage triggers a chemical reaction that uses extra building blocks (called monomers) already present in the gel.

- These monomers attach to the broken spots, creating new, stronger bonds. As a result, the gel becomes tougher exactly where it was stressed.

Why Is This Important?

This innovation is important because it imitates the way real muscles get stronger with use. When you exercise, your muscles develop tiny tears that heal and rebuild, making them stronger. This gel does something similar, but at the molecular level. The process opens up new possibilities for robotics, medical devices, and wearable technology, where materials that adapt and self-repair are highly valuable.

The Science Behind the Strength

The development of this gel polymer combines chemistry, computer modeling, and materials science. Here’s how the science works:

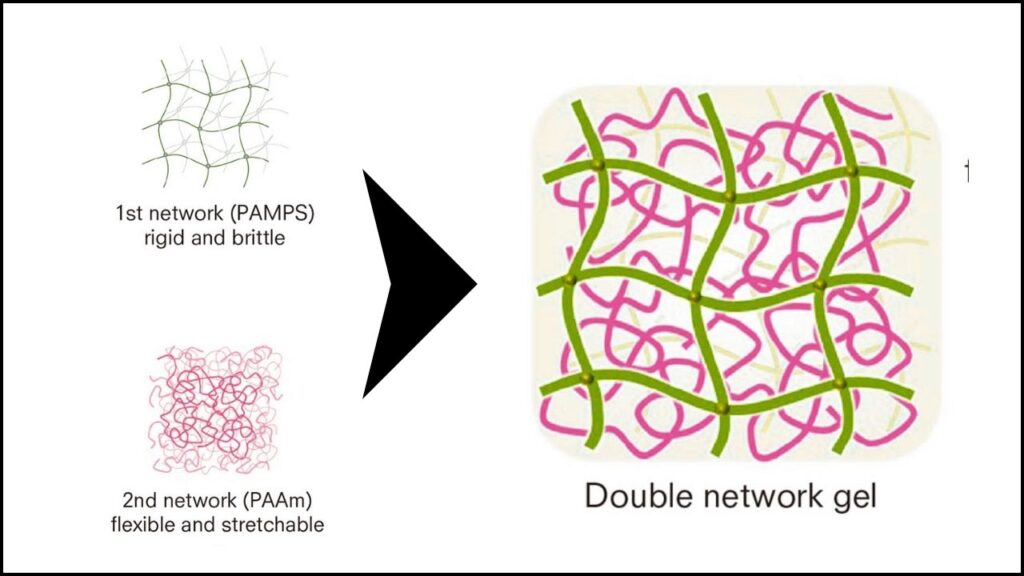

1. Double-Network Hydrogels

- Double-network hydrogels are made from two different types of polymers:

- The first network is rigid and brittle, providing initial strength.

- The second is soft and flexible, allowing the gel to stretch and recover.

- When the gel is stressed, the rigid network breaks at weak points, but instead of leading to failure, this breakage triggers a chemical process that builds new, stronger bonds.

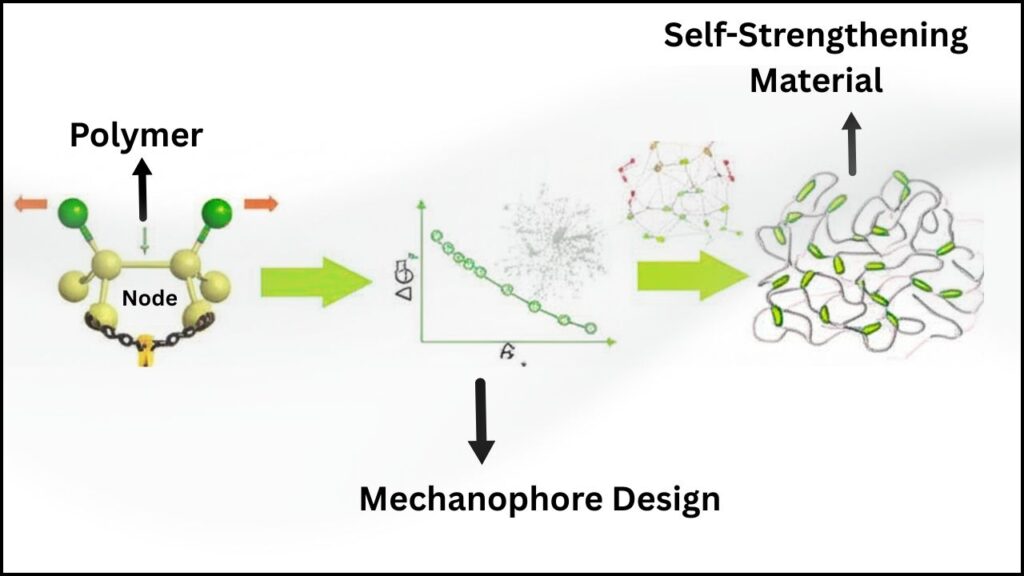

2. Mechanophores: The Force Sensors

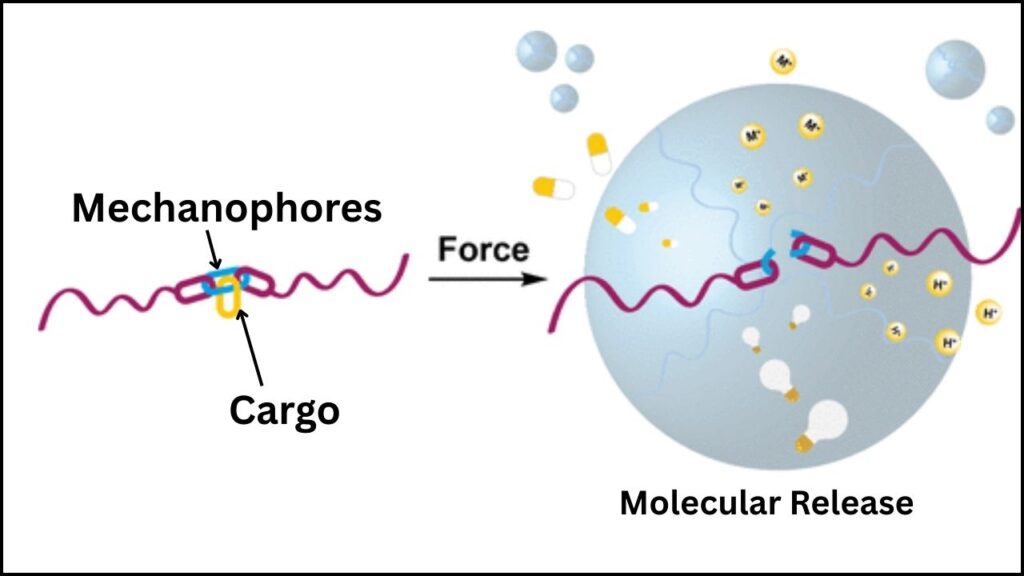

- Mechanophores are special molecules that react when force is applied to them.

- By carefully choosing the right mechanophores, scientists can control how and when the gel reinforces itself.

- The latest research uses advanced computer modeling to select mechanophores that are sensitive to mechanical force but stable against heat and light, ensuring the gel is both responsive and durable.

3. Artificial Force Induced Reaction (AFIR)

- The AFIR method is a computational technique that predicts how molecules will react when pulled or stretched.

- This allows researchers to design gels that are optimized for real-world use—strong, stable, and able to self-repair exactly where needed.

Real-World Applications: Where Will We See This Technology?

Soft Robotics

Soft robots are made from materials that can bend, stretch, and move in ways traditional robots can’t. With this new gel, soft robots could have muscle-like movement and self-healing abilities. This means they could be used for delicate tasks in medicine or industry, adapting to new challenges and lasting longer.

Medical Implants and Prosthetics

The gel’s ability to integrate with living tissue and reinforce itself makes it a promising material for medical implants and prosthetic limbs. Artificial muscles made from this gel could provide more natural movement and strength, improving the quality of life for people with limb loss or muscle injuries.

Wearable Technology

Imagine smart clothing or exosuits that get tougher the more you use them. This gel could be used in sports gear, medical braces, or even everyday clothing to provide support that adapts to your activity level.

Regenerative Medicine

Because the gel can promote healing and tissue growth, it could be used as a scaffold for growing new muscle tissue in people who’ve suffered severe injuries. This opens up new possibilities for treating muscle loss and other conditions.

Practical Guide: How Does the Gel Polymer Actually Work?

Let’s break down the process in simple steps:

Step 1: Building the Gel

Scientists start by mixing two types of polymers:

- A brittle polymer that breaks under force.

- A stretchy polymer that holds the gel together.

They add monomers (tiny building blocks) and mechanophores (force-sensitive molecules) into the mix.

Step 2: Applying Stress

When the gel is stretched or squeezed, the brittle network breaks at its weakest points. This breakage creates reactive sites—like tiny hooks—ready to grab onto the monomers.

Step 3: Self-Strengthening

The monomers attach to the broken spots, forming new, stronger bonds. The gel heals and becomes tougher exactly where it was stressed.

Step 4: Repeat and Reinforce

Each time the gel is used, it adapts and gets stronger, just like a muscle after exercise.

Example: Robotic Gripper

Imagine a robotic gripper made from this gel. Every time it picks up a heavy object, the parts under the most stress reinforce themselves. Over time, the gripper becomes more reliable and less likely to break, making it perfect for demanding tasks in factories or hospitals.

Data and Statistics: How Strong Is the New Gel Polymer?

- Strength Increase: The gel can become up to 1.5 times stronger after repeated use.

- Stiffness: It can become 23 times stiffer after stress cycles.

- Weight Gain: Polymer weight can increase by up to 86% as new bonds form.

- Toughness: Some artificial muscle polymers can reach tensile strengths far beyond those of traditional hydrogels, with high stretch and resilience.

- Industry Value: The global artificial muscle market is valued at over US$2.1 billion in 2025 and is expected to double by 2032.

These numbers show that the new gel is not just a laboratory curiosity—it’s a practical material with real-world potential.

New Polymer Fiber Breakthrough Releases Antibacterial Drugs Only When Needed

New Polymer Breakthrough Boosts Durability and Sustainability Using Green Chemistry

Custom Polymers Offer Efficient Electrochemical Separations for Greener Drug Production

FAQs About New Gel Polymer Mimics Muscle and Gains Strength With an Innovative Formula

What is a hydrogel?

A hydrogel is a soft, jelly-like material made mostly of water and polymers. It’s used in products like contact lenses, wound dressings, and now, advanced robotics and medicine.

How does this gel polymer mimic muscle?

It copies the way real muscle gets stronger with use. When the gel is stretched, it repairs itself and adds new material, just like muscles do after exercise.

Is the gel safe for medical use?

Yes. The polymers used are designed to be biocompatible, meaning they can safely interact with living tissue.

Can the gel be used in robots?

Absolutely! Its self-strengthening and flexible nature make it ideal for soft robots and artificial muscles.

How long does it take for the gel to get stronger?

The strengthening happens quickly—often during or right after the stress is applied.

What are mechanophores?

Mechanophores are molecules that react to mechanical force, helping the gel know when and where to reinforce itself.

The Future of Muscle-Like Gel Polymers

The development of a gel polymer that mimics muscle and gains strength with use is a major step forward in materials science. This innovation shows how combining inspiration from nature with advanced chemistry and computer modeling can lead to materials that adapt, heal, and grow stronger over time.

Professional Impact

- Engineers can design robots and devices that last longer and require less maintenance.

- Doctors and medical researchers can explore new treatments for muscle injuries and more natural prosthetics.

- Manufacturers can create products that adapt to wear and tear, reducing waste and improving performance.

Everyday Impact

For everyday people, this could mean smarter clothing, safer medical devices, and more reliable robots in our homes and workplaces. The possibilities are just beginning to emerge, and as research continues, we can expect even more exciting applications.