New Geopolymer Tech Transforms Glass and Waste Into Ultra-Durable Green Building Material: In an exciting leap toward sustainable construction, new geopolymer technology is turning recycled glass and industrial waste into ultra-durable, eco-friendly building materials. Spearheaded by researchers at Japan’s Shibaura Institute of Technology, this innovation offers a real solution to two pressing global challenges: construction waste and carbon emissions.

For decades, the construction industry has leaned heavily on Portland cement, a carbon-intensive material responsible for up to 8% of global CO₂ emissions, according to the International Energy Agency (IEA). With landfills overflowing and climate change accelerating, this new geopolymer tech offers a cleaner, stronger, and smarter alternative—without compromising performance.

Table of Contents

New Geopolymer Tech Transforms Glass and Waste Into Ultra-Durable Green Building Material

| Feature | Details |

|---|---|

| What It Is | A geopolymer solidifier made from recycled glass and construction waste |

| Developed By | Shibaura Institute of Technology |

| Main Materials | Siding Cut Powder (SCP) and Earth Silica (ES) |

| Strength | Exceeds 160 kN/m², above required construction thresholds |

| Environmental Benefit | Cuts cement use and reduces CO₂ emissions up to 80% |

| Applications | Roads, foundations, disaster zones, rural housing |

| Safety Feature | Treated to prevent arsenic leaching using calcium hydroxide |

| Official Source | TechXplore Coverage |

Geopolymer technology is redefining the future of construction. With its ability to transform recycled glass and waste into durable, safe, and low-carbon building materials, it solves both ecological and industrial challenges. As cities race to decarbonize and innovate, this approach offers a real, ready solution.

From roads to disaster shelters, rural homes to smart cities, this isn’t just innovation—it’s transformation. Professionals, policymakers, and citizens alike have a role to play in advancing this green frontier.

What Is Geopolymer Technology?

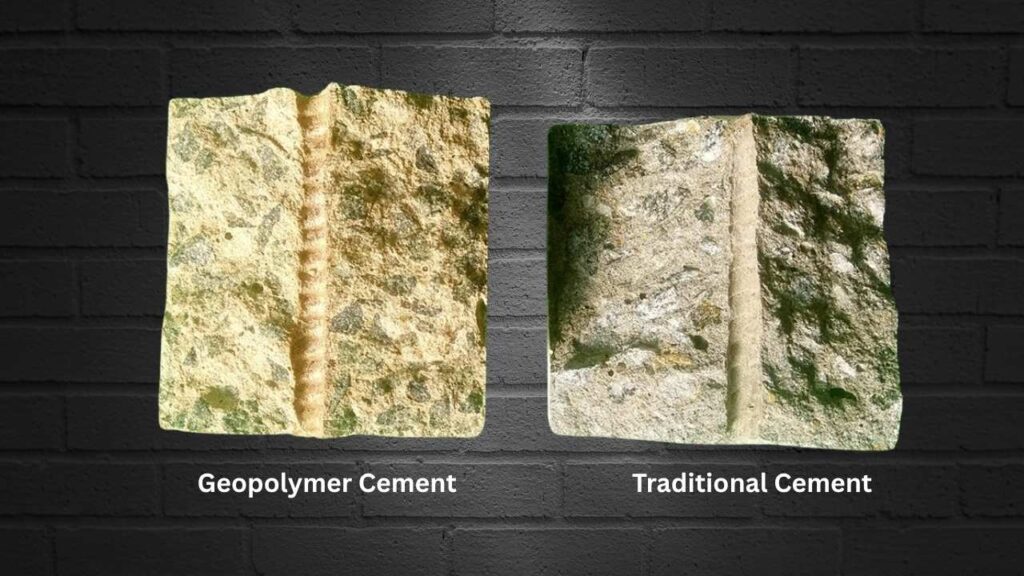

Let’s break it down simply: Geopolymers are innovative binders created by combining waste-based materials with an alkaline activator. This chemical reaction—called geopolymerization—forms a hard, durable substance that can outperform traditional cement in strength and resilience.

Eco-Friendly Chemistry

Instead of burning limestone (as with cement), geopolymer production uses lower temperatures, emits fewer greenhouse gases, and recycles industrial byproducts like:

- Siding Cut Powder (SCP) – waste from construction and demolition sites

- Earth Silica (ES) – derived from ground, recycled glass

Geopolymer vs. Traditional Cement: A Comparison

| Feature | Geopolymer | Portland Cement |

|---|---|---|

| Carbon Emissions | Low (up to 80% less) | High (0.9 tons CO₂ per ton) |

| Raw Materials | Recycled glass, SCP | Mined limestone, clay |

| Durability | High: Resistant to chemicals, salt, and weather | Moderate |

| Curing Time | Fast | Standard |

| Cost | Potentially lower with scaling | Increasing due to energy costs |

| Environmental Impact | Positive: Waste reduction | Negative: High CO₂ and resource use |

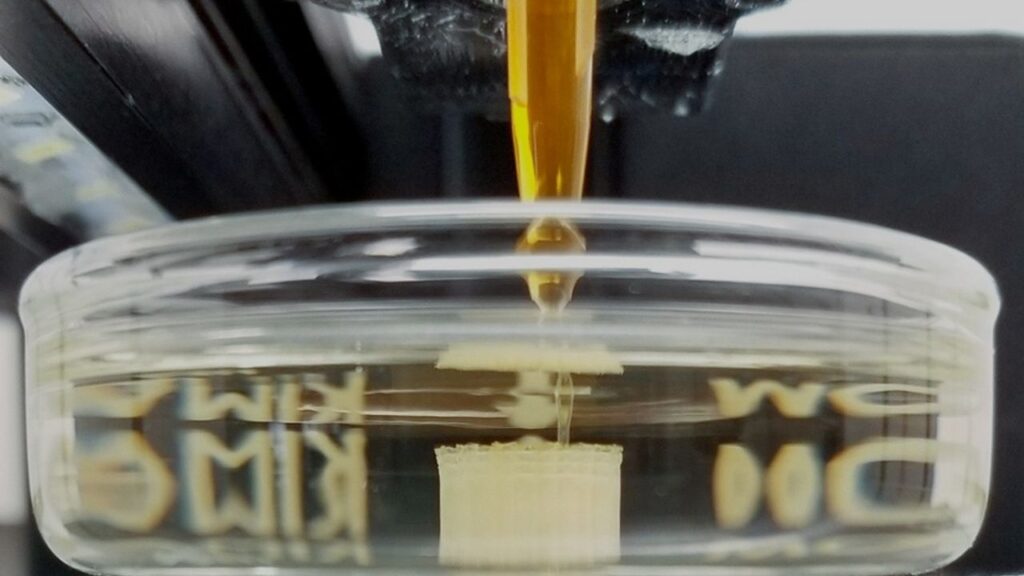

How It Works: Step-by-Step

Step 1: Collect Waste

Glass bottles, construction debris, and leftover siding are crushed and filtered into powder.

Step 2: Activate with Earth Silica

Glass powder is transformed into Earth Silica, a strong alkaline substance that triggers binding.

Step 3: Mix and Mold

Once combined, the mix sets into a solid block or soil stabilizer.

Step 4: Cure and Apply

No high-temperature curing needed—just mold and apply to roads, building foundations, or soil.

Real-World Applications

This is not just a lab concept—it’s being tested in the real world across Japan and beyond.

Infrastructure Projects

Used in roadbeds, bridge supports, and embankments due to 160 kN/m² strength rating.

Disaster-Resistant Construction

In flood or earthquake-prone areas, this tech provides fast soil solidification, reducing collapse risk.

Rural and Off-Grid Housing

It can be molded into affordable bricks or blocks, enabling sustainable housing in remote areas.

Smart Cities and Eco-Towns

Green construction materials are a key pillar of smart city development, making this geopolymer tech highly valuable.

“We’re taking waste destined for landfills and turning it into the future of construction,” says Professor Shinya Inazumi.

Environmental and Economic Benefits

Waste Reduction

Saves thousands of tons of glass and SCP from landfills annually.

Emission Cuts

Cement alternatives reduce global CO₂ footprints—vital for meeting Net Zero targets by 2050.

Water Efficiency

Requires less water than concrete mixing—important for arid regions.

Lower Long-Term Costs

Material availability + easy production = lower costs as production scales.

Expert Insight and Industry Momentum

According to AZoBuild, the geopolymer binder has passed critical performance tests, including:

- Sulfate resistance

- Chloride ion penetration

- Thermal cycling

This makes it suitable for marine, urban, and desert conditions, offering a versatile foundation for global infrastructure needs.

Challenges and Limitations

While promising, geopolymer tech still faces:

- Scaling and consistency – Adapting recipes across regions can be complex

- Regulatory approvals – Needs to pass codes in various countries

- Public awareness – Builders and architects may resist changing from cement

However, these are expected to ease as field trials expand and costs drop.

How Professionals Can Use This Technology

If you’re in construction, engineering, architecture, or policy, here’s how to engage:

- Stay Updated: Follow updates from Shibaura Institute of Technology

- Partner for Pilots: Cities or NGOs can collaborate on local tests

- Specify in Designs: Green specs help win LEED points and grants

- Advocate Policy Change: Push for fast-tracked approval of low-carbon materials

AI-Driven Models Accelerate Molecular and Materials Discovery in Biomedical Research

Superconducting Diode Bridge Efficiently Converts AC to DC for Quantum Circuits

China Develops High-Resolution Laser Capable of Reading Tiny Text from Over a Kilometer Away

FAQs About New Geopolymer Tech Transforms Glass and Waste Into Ultra-Durable Green Building Material

Is this stronger than concrete?

Yes—lab tests show it meets and often exceeds compressive strength standards.

Can I use it at home?

Not yet mainstream for DIY, but it will likely be available in prefab blocks by 2026–27.

What happens if it gets wet or salty?

No problem. It’s resistant to water damage, corrosion, and salt, making it ideal for coastal areas.

Can it be painted or finished?

Yes. Once cured, it behaves like concrete and can be coated, sealed, or shaped.