In the quest for a sustainable future powered by electric vehicles and renewable energy, lithium has emerged as a vital resource. As demand for lithium-ion batteries skyrockets, mining lithium through traditional methods is proving expensive, slow, and environmentally harmful. But imagine if we could extract lithium directly from water — seawater, underground saltwater, and brines — using new membrane technology that acts like an ultra-selective filter. This exciting innovation could revolutionize lithium production, making it cleaner, cheaper, and scalable. Could this be the key to solving the global battery crisis?

Table of Contents

New Membrane Tech Extracts Lithium From Water

| Feature | Details |

|---|---|

| Traditional lithium sources | Hard-rock mining and salt lakes, requiring millions of liters of water per ton, with high environmental impact |

| Membrane materials | Vermiculite clay membranes, polymer membranes with crown ethers, covalent organic frameworks (COFs) |

| Extraction efficiency | Selectivity up to ~99% and extraction efficiency over 80% |

| Environmental benefits | Significant reductions in water use, carbon emissions, and chemical waste compared to traditional methods |

| Current challenges | Higher initial membrane costs, membrane durability, and scale-up complexity |

| Key developers & innovators | Argonne National Laboratory, EnergyX, Pure Lithium, ElectraLith, LiTHOS |

| Applications | Extraction from seawater, geothermal brines, wastewater, and recycled battery materials |

| Official reference | Argonne National Laboratory research: ANL website |

Membrane technology is an exciting breakthrough in lithium extraction, with the potential to reshape the battery supply landscape. By filtering lithium directly from water sources in a selective, environmentally friendly way, ultrathin membranes could ease global lithium shortages while cutting environmental harm drastically. Combined with renewable energy and ongoing material innovations, this approach may power the green energy revolution sustainably and reliably in the coming decade.

Why Lithium Extraction Matters and Its Challenges

Lithium-ion batteries power smartphones, laptops, electric cars, and energy storage grids. As the world accelerates toward carbon neutrality, lithium demand will continue growing rapidly.

Traditional extraction methods include:

- Hard-rock mining (e.g., spodumene ores)

- Evaporation of salt brines from salt lakes in countries like Chile and Australia

However, these methods are:

- Water-intensive: approximately 2 million liters of water are used per ton of lithium extracted, leading to freshwater depletion and harm to ecosystems.

- Slow: evaporation ponds require 12-18 months to concentrate lithium.

- Environmentally damaging: high carbon emissions, land disruption, and chemical pollution.

Interestingly, most of Earth’s lithium exists in dissolved form in vast quantities of seawater and underground brines. But lithium ions in seawater appear at an extremely low concentration (~0.17 parts per million) and are mixed with much higher amounts of sodium and magnesium ions. This makes isolating lithium very challenging with conventional methods.

What Is Membrane Lithium Extraction?

Membrane lithium extraction uses ultrathin, highly selective filters that allow lithium ions to pass while blocking other ions like sodium and magnesium. This is achieved by designing membranes at the nanoscale, finely tuned to lithium’s characteristics.

Main types include:

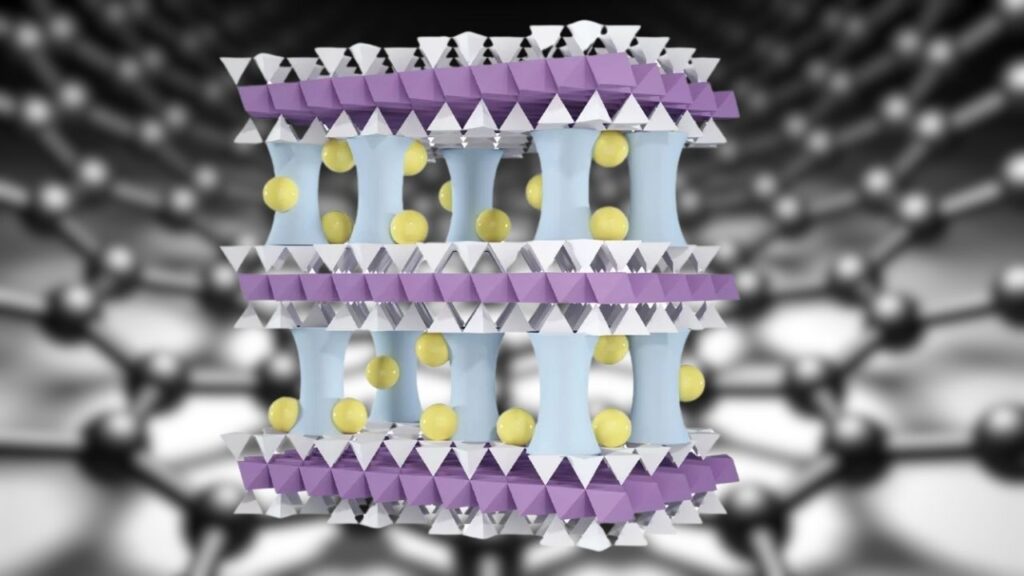

- Vermiculite clay-based membranes: Natural clay is exfoliated into 2D sheets a billionth of a meter thick. These sheets are held apart by microscopic aluminum oxide ‘pillars’ that stabilize the structure and give it a positive surface charge, repelling magnesium ions (which have a +2 charge) more than lithium ions (+1 charge). This yields lithium-rich permeate water.

- Polymer membranes with crown ethers: Crown ethers are ring-shaped molecules that bind lithium ions selectively, facilitating their transport while excluding other ions.

- Covalent Organic Frameworks (COFs): Highly customizable porous materials that allow lithium ions through selective channels while blocking others.

For example, researchers at the U.S. Department of Energy’s Argonne National Laboratory have developed vermiculite-based membranes with outstanding lithium selectivity and efficiency, showing strong potential for industrial use.

Advantages of Membrane Technology for Lithium Extraction

- Environmentally Friendly: Membrane processes consume far less water and energy, drastically reducing carbon footprint and chemical usage.

- High Selectivity & Efficiency: New membranes achieve lithium purity levels of nearly 99% and extraction efficiencies exceeding 80%, surpassing many conventional methods.

- Versatility & Scalability: Membranes can be used with seawater, geothermal brines, industrial wastewater, and recycled battery material, diversifying lithium sources and lowering geopolitical risks.

- Renewable Energy Integration: Emerging designs operate with renewable power inputs like solar or wind, further cutting emissions.

- Lower Land Impact: Unlike salt ponds and mines, membrane systems require smaller footprints and avoid ecological disruption.

Current Challenges and Developments

Despite promising advances, membrane technology faces several hurdles:

- Membrane Cost and Lifespan: High-performance membranes currently cost more and may degrade over time, requiring replacement.

- Scaling Up: Processing huge volumes of water for commercial lithium extraction demands engineering innovation and operational efficiency improvement.

- Membrane Fouling: Natural waters contain contaminants that can clog membranes, necessitating pre-treatment and thorough cleaning cycles.

Ongoing research and companies like EnergyX, Pure Lithium, and ElectraLith are addressing these issues by developing more durable membranes and integrating recycling of process water to optimize sustainability.

How Membrane Lithium Extraction Works: Step-by-Step

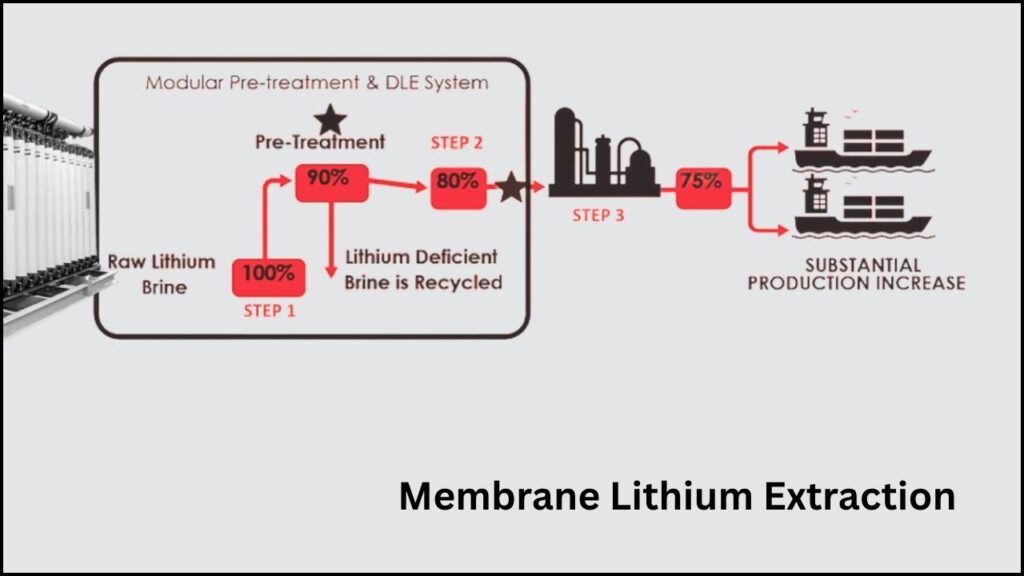

- Select Water Source: Seawater, underground brine, salty lake water, or industrial wastewater that contains dissolved lithium.

- Pre-Treatment: Filter out particulates, organic matter, and other contaminants to protect membranes.

- Filtration & Separation: Pass water through selective membranes where lithium ions permeate and competing ions are blocked.

- Lithium Concentration: Collect the lithium-enriched permeate to concentrate lithium into commercially useful solutions.

- Chemical Refinement: Treat concentrated lithium solution to produce battery-grade lithium compounds like lithium carbonate or lithium hydroxide.

- Membrane Cleaning and Regeneration: Regular maintenance restores membranes for repeated use, sustaining efficiency.

Real-World Benefits and Future Outlook

Membrane extraction technology promises to transform lithium supply chains by:

- Enabling localized lithium production in coastal regions from seawater, reducing reliance on traditional mining hubs.

- Minimizing environmental damage with drastically lower water consumption, land disruption, and pollution.

- Increasing supply security, helping meet global demand without exacerbating geopolitical tensions.

- Potentially lowering costs over time through energy savings and operational efficiencies.

While full commercial-scale membrane plants are still emerging, current research milestones point to widespread adoption within the next 5 to 10 years.

Lithium Universe Secures Global Rights for Microwave-Assisted Solar Panel Recycling Technology

Zinciodine Battery Offers a New Alternative to Lithium-Ion Technology

Next-Generation EV Battery Design Uses Less Lithium While Delivering Strong Performance

FAQs About New Membrane Tech Extracts Lithium From Water

Q: Can membranes extract lithium effectively from seawater’s low lithium concentrations?

A: Yes. Advanced membranes achieve high selectivity that isolates lithium ions even when mixed with much larger amounts of other ions, concentrating lithium to usable levels.

Q: How eco-friendly is membrane lithium extraction?

A: It uses significantly less water, energy, and chemicals than traditional mining, lowering carbon footprint and preserving ecosystems.

Q: When will membrane lithium extraction become widespread commercially?

A: Pilot plants exist today, with commercial scaling expected in 5–10 years as costs drop and durability improves.

Q: Is membrane-extracted lithium pure enough for battery manufacturing?

A: Membrane processes can yield lithium with purity exceeding 99%, meeting battery industry specifications.

Q: Are membranes reusable?

A: Yes, membranes can be cleaned and regenerated regularly, although lifespan depends on material quality and feed water conditions.