Silicon is one of the most important materials in modern technology—from computers and smartphones to solar panels and advanced electronics. Scientists have now developed an exciting new method that can temporarily “pause” the ultrafast melting of silicon using precisely timed laser pulses. This breakthrough reveals novel ways to control materials at atomic levels and could revolutionize how we understand and manipulate solid materials in the future.

What Is the New Timed Laser Method?

Traditionally, when silicon is hit with an intense laser pulse, it melts extremely quickly—within a fraction of a trillionth of a second. This process, called nonthermal melting, happens so fast that the silicon atoms lose their orderly crystal structure before they even heat up noticeably.

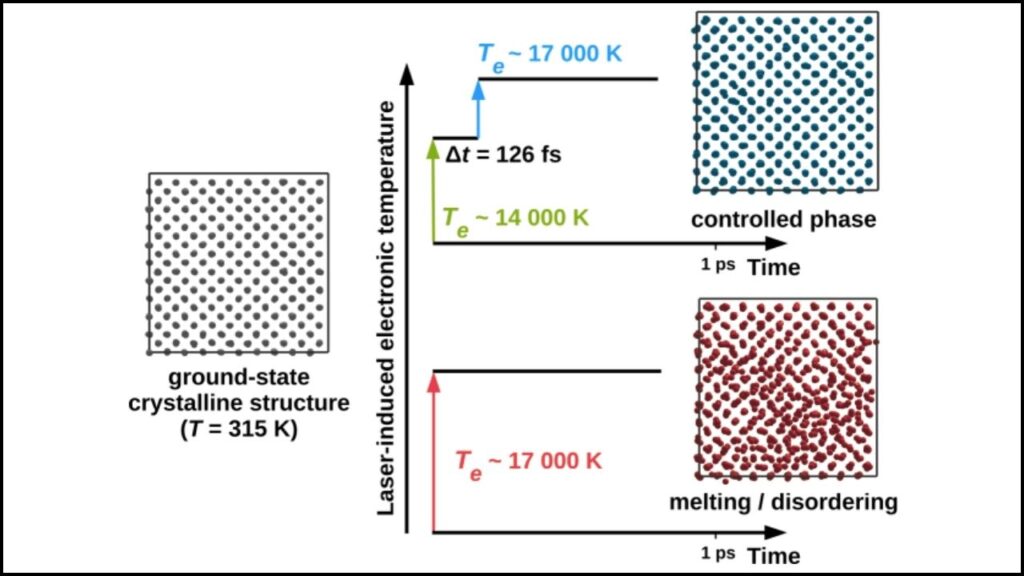

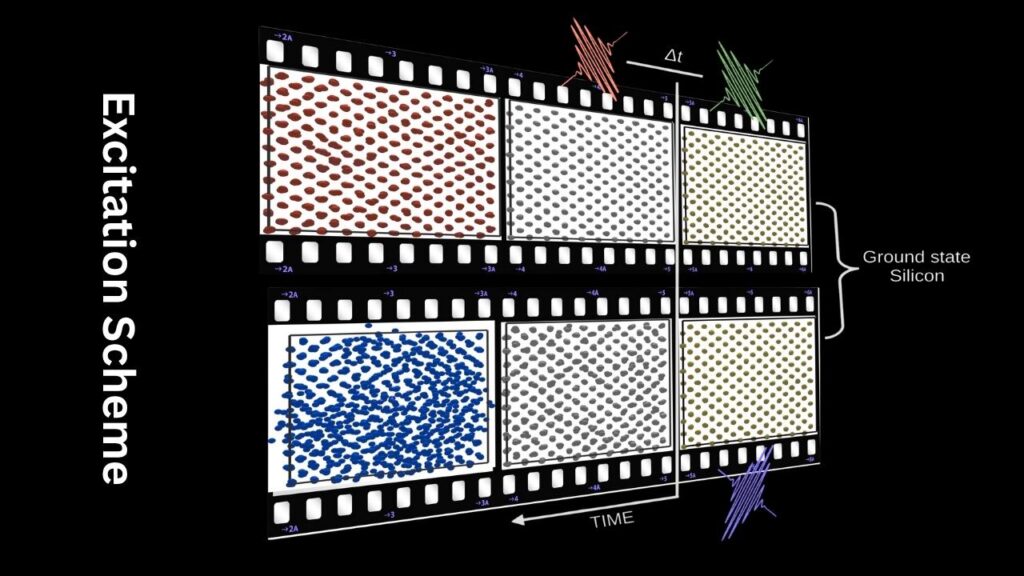

However, scientists from the University of California, Merced, and the University of Kassel in Germany have discovered that by splitting a laser beam into two ultra-short pulses (each lasting only a few femtoseconds—one femtosecond is one quadrillionth of a second) and carefully timing the delay between them to about 126 femtoseconds, they can interrupt this melting process and effectively “freeze” the silicon in a new, metastable solid state.

This metastable state maintains much of the silicon’s original crystal properties and exhibits cooler, more stable vibrations of its atoms, even though the material has absorbed enough energy to normally melt. This means the atomic motion that leads to melting is put on hold temporarily by the laser pulse sequence.

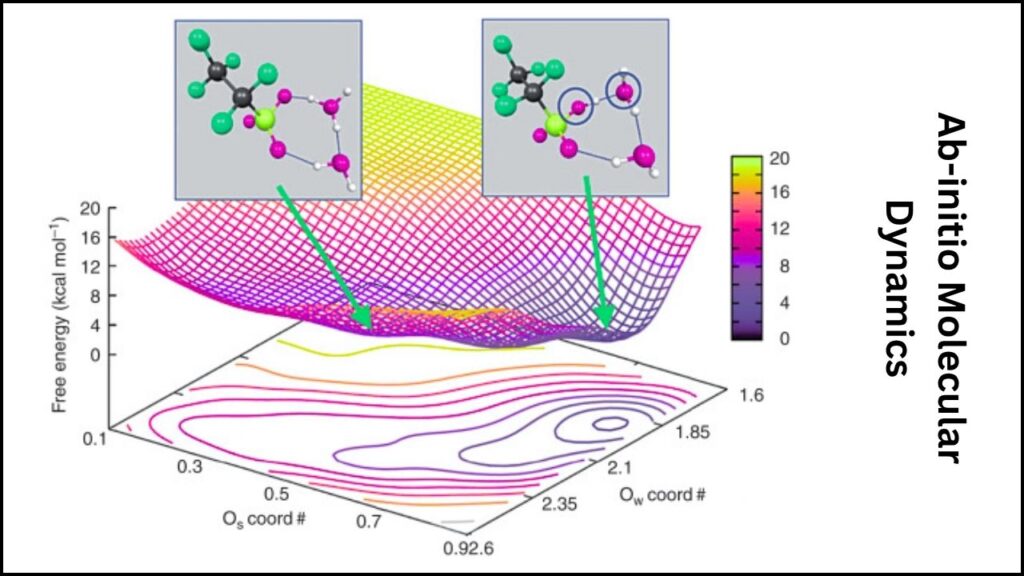

Using advanced ab initio molecular dynamics simulations—which model atoms and electrons from first principles—the team showed that the first laser pulse excites the atoms, while the second pulse constructs an interference effect that prevents atoms from becoming disordered, thereby stabilizing the solid structure for a brief moment.

Why This Discovery Matters

- New Material Control Opportunities: This technique allows researchers to manipulate the phases of materials on incredibly fast timescales and with unprecedented precision. It opens the door to exploring and stabilizing new phases of matter that are not usually accessible under normal conditions.

- Enhanced Experimental Accuracy: By pausing structural changes, this approach can improve the accuracy of experiments that study how energy moves between electrons and atoms in solids. Understanding these energy transfers is crucial for designing better electronic and photonic devices.

- Potential Applications Beyond Silicon: Although demonstrated with silicon, the method may be adapted for other materials exhibiting similar ultrafast melting behavior, possibly leading to advances in various fields such as semiconductor manufacturing, nanotechnology, and materials science.

New Timed Laser Method Lets Scientists Hit ‘Pause’ on Ultra-Fast Silicon Melting

| Aspect | Details |

|---|---|

| Material Studied | Silicon |

| Technique | Timed double femtosecond laser pulses (126 fs apart) |

| Melting Type | Nonthermal melting paused temporarily |

| Simulation Method | Ab initio molecular dynamics |

| Metastable State Characteristics | Maintains electronic properties, cooler atomic vibrations, temporarily frozen atomic motion |

| Potential Applications | Semiconductor manufacturing, energy transfer studies, material phase engineering |

The new timed laser pulse technique to pause silicon’s ultrafast melting is a breakthrough in materials science. It allows scientists to hit pause on atomic motion during laser excitation, creating a temporary, stable solid phase where melting is stopped mid-process. This advancement offers exciting possibilities for semiconductor manufacturing, fundamental physics, and innovative material design. As research progresses, this could transform how we interact with and manipulate materials at ultrafast timescales.

Understanding Ultrafast Melting in Silicon: A Simple Guide

What Happens When Silicon Melts?

When silicon melts under normal heating, its atoms gain energy and vibrate more, eventually breaking the orderly crystalline structure to become a liquid.

In ultrafast laser melting, the process is different—called nonthermal melting—where the laser excites electrons so rapidly that the atoms lose their orderly pattern even before they heat up. This happens in femtoseconds, far quicker than traditional melting.

How Does the Timed Laser Method Work?

The new method uses two ultra-short laser pulses separated by an exact interval. Here’s a breakdown:

- Pulse One: Delivers energy to the silicon atoms, exciting them and starting the melting process.

- Pulse Two: Arrives just in time (126 femtoseconds later) to interfere with this motion. Rather than allowing the atoms to lose order and melt, this pulse stabilizes and “freezes” atomic vibrations.

Scientists describe this as causing quantum coherence and constructive interference of atomic vibrations—meaning the laser pulses work together like perfectly timed waves to control how atoms move.

Why Is This Important for Everyday Technology?

Silicon is the backbone of electronics and solar cells. Being able to control its melting and structural changes on ultrafast timescales can:

- Improve the manufacturing of microchips by allowing precise manipulation during laser processing.

- Help design faster and more reliable semiconductor devices.

- Provide insights into energy conversion processes in materials, potentially influencing solar energy and optical technologies.

Practical Applications and Future Directions

While this discovery is still within research phases, here’s how it might impact fields in the near future:

1. Semiconductor Industry

Laser pulses are commonly used in chip manufacturing for doping (adding impurities), annealing (heating to repair damage), and patterning. This precise control over melting could allow manufacturers to:

- Reduce defects by controlling material phases more accurately.

- Create new silicon-based materials with enhanced electronics or optical properties.

2. Material Science Research

Researchers studying ultrafast processes and phase transformations can use this method to:

- Explore new metastable phases of silicon or other materials.

- Test theories on laser-matter interaction with better experimental control.

3. Energy Transfer Studies

By pausing melting, scientists can isolate and better understand:

- How energy moves between electrons and atomic nuclei.

- The fundamental physics behind light-matter interactions on extremely short timescales.

Peacock Feathers Turn Into Living Lasers — Nature’s Weirdest Tech Yet

Berkeley Lab Introduces Laser‑Patterned Color‑Center Qubits in Silicon

FAQs About New Timed Laser Method Lets Scientists Hit ‘Pause’ on Ultra-Fast Silicon Melting

Q1: What is “nonthermal melting?”

Nonthermal melting occurs when a material’s atomic structure becomes disordered due to rapid electronic excitation, rather than by heating the material’s atoms to high temperatures. It happens in femtoseconds, much faster than traditional melting.

Q2: How fast is a femtosecond?

One femtosecond (fs) is one quadrillionth (10^-15) of a second—an unimaginably short time scale where atomic vibrations and electron movements occur.

Q3: Why use two laser pulses instead of one?

Two pulses timed exactly allow the second to interfere with and control atomic movement initiated by the first, effectively pausing the melting process temporarily.

Q4: Can this method be used with other materials?

The research suggests materials with similar ultrafast melting behavior might be controlled using this approach. Future studies will explore its broader applicability.

Q5: How does this discovery affect everyday electronics?

Though primarily fundamental research now, it could lead to better manufacturing processes and new material states for electronics, potentially improving device performance and durability.