Next-Generation EV Battery Design: As the global electric vehicle (EV) market accelerates, the demand for batteries that are not only powerful and efficient but also cost-effective and environmentally sustainable is growing rapidly. One of the most promising areas of innovation is in next-generation EV battery designs that use less lithium while still delivering strong performance. This shift aims to reduce reliance on lithium—a limited and expensive resource—while maintaining or improving battery range, charging speed, and safety.

In this comprehensive article, we’ll explore the latest advancements in battery technology that address these challenges, break down complex concepts into digestible insights, and offer a clear picture of what these innovations mean for consumers, manufacturers, and the environment. Whether you’re new to EVs or a seasoned industry professional, this guide will help you understand the future of electric mobility powered by smarter batteries.

Table of Contents

Next-Generation EV Battery Design

| Feature | Details |

|---|---|

| Primary Innovation | Batteries that reduce lithium content without sacrificing performance |

| Key Technologies Covered | Sodium-ion, lithium-sulfur, solid-state, anode-free, magnesium-sulfur, potassium-ion batteries |

| Main Benefits | Lower raw material costs, reduced environmental impact, improved safety, enhanced battery life |

| Leading Companies | CATL, Nissan, QuantumScape, Sion Power, Faradion |

| Commercial Status | Sodium-ion batteries commercially available in select markets; others in pilot or development phase |

| Official Reference | U.S. Department of Energy: Batteries and Energy Storage |

The shift towards next-generation EV batteries using less lithium is crucial for sustainable and affordable electric mobility. Technologies like sodium-ion, lithium-sulfur, and solid-state batteries are paving the way to batteries that offer strong performance, improved safety, and reduced environmental impact.

While challenges remain, the progress from leading companies and research institutions indicates that these batteries will become increasingly common over the next decade. For EV buyers, manufacturers, and policymakers alike, understanding and supporting these innovations is key to driving the clean transportation revolution forward.

Why Is Reducing Lithium Important?

Lithium’s Role and Challenges

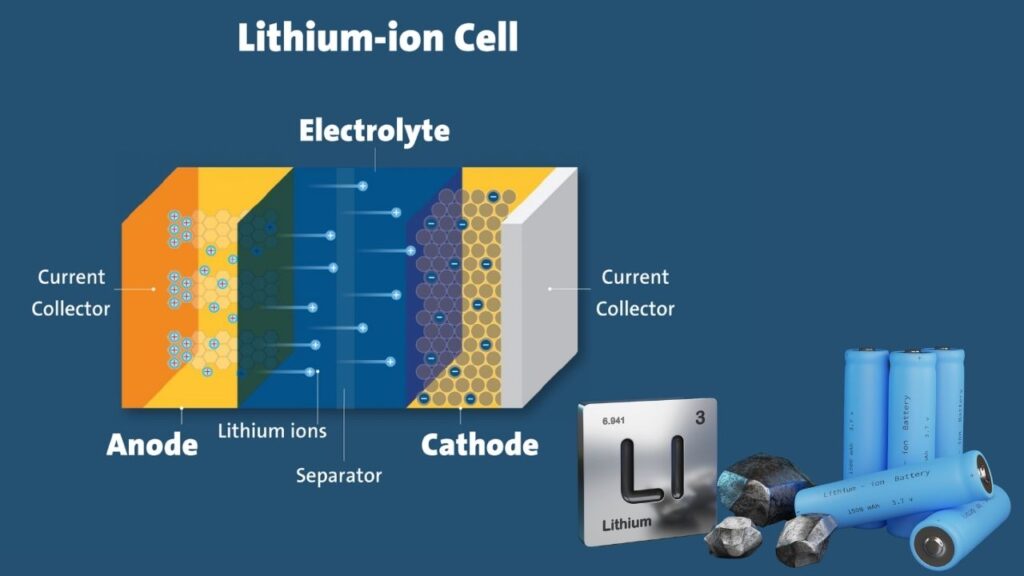

Lithium-ion batteries have been the backbone of EV energy storage for over a decade. Lithium’s high energy density and relatively light weight make it ideal for powering cars. However, lithium comes with several challenges:

- Resource scarcity: Lithium reserves are concentrated in a few countries like Australia, Chile, and Argentina. Rapidly increasing EV demand strains these reserves.

- Price volatility: Lithium prices have experienced sharp increases recently due to supply-demand imbalances.

- Environmental impact: Lithium extraction can consume vast amounts of water and cause ecological damage, particularly in sensitive regions like the Atacama Desert.

- Geopolitical risks: Reliance on few geographic sources poses risks to supply chain stability.

According to the International Energy Agency (IEA), global lithium demand for EV batteries could increase from 300,000 metric tons in 2020 to over 3.4 million metric tons by 2030, a more than tenfold increase. This unsustainable growth demands alternative approaches.

The Goal: Less Lithium, More Sustainability

Reducing lithium content or replacing lithium entirely with more abundant elements can:

- Lower battery production costs, making EVs more affordable.

- Reduce environmental harm by minimizing mining impacts.

- Mitigate supply chain risks by using widely available materials.

- Enhance battery safety and longevity through new chemistries and designs.

Exploring Next-Generation Battery Technologies

Sodium-Ion Batteries: Abundant and Affordable

Sodium-ion batteries replace lithium ions with sodium ions to shuttle charge between electrodes. Sodium shares similar chemical properties with lithium but is far more abundant and evenly distributed globally.

Advantages:

- Abundance: Sodium is plentiful and inexpensive, reducing material costs.

- Good performance: Recent advances have improved energy density to about 160–200 Wh/kg, nearing that of older lithium-ion cells.

- Safety: Sodium-ion batteries exhibit stable thermal properties and are less prone to overheating.

- Fast charging: Some sodium-ion cells support rapid charging without degrading quickly.

Challenges:

- Sodium ions are larger than lithium ions, which can limit capacity and cycle life.

- Lower voltage compared to lithium-ion cells means less energy per cell.

Industry progress:

- CATL launched its Naxtra sodium-ion batteries commercially in 2023, offering up to 500 km range in select EVs.

- Faradion, a UK company, has developed high-performance sodium-ion cells with good energy density and cycle life, targeting commercial vehicles and grid storage.

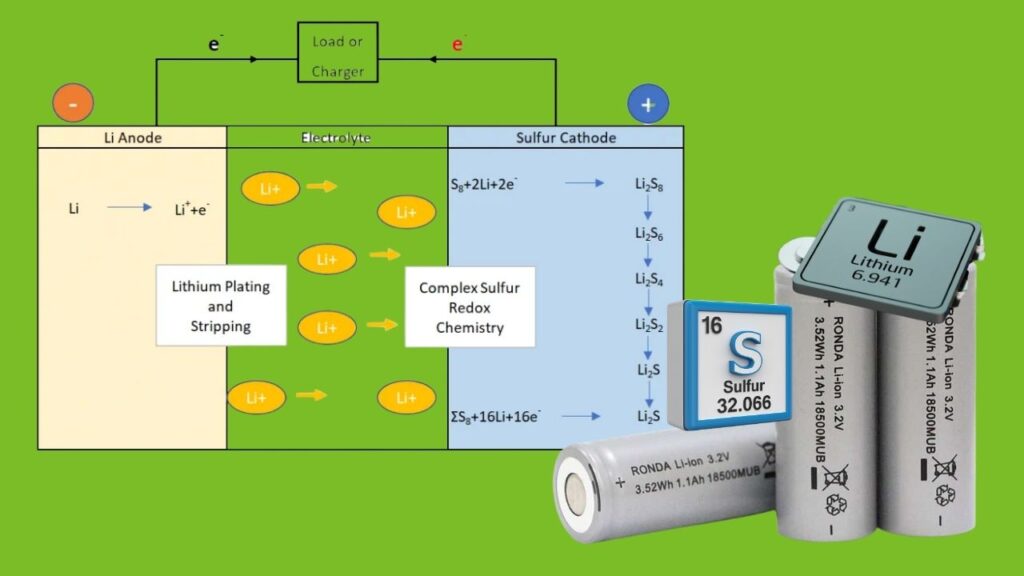

Lithium-Sulfur Batteries: High Energy Density with Less Lithium

Lithium-sulfur (Li-S) batteries use sulfur as the cathode material, which is abundant and inexpensive. This chemistry allows for significantly higher theoretical energy densities than traditional lithium-ion batteries.

Advantages:

- Energy density: Theoretical values exceed 500 Wh/kg, potentially doubling current EV ranges.

- Lower cost: Sulfur is cheap and abundant.

- Lightweight: Li-S batteries weigh less, beneficial for vehicle efficiency.

Challenges:

- The “shuttle effect” causes sulfur to dissolve into the electrolyte during cycling, leading to capacity loss.

- Cycle life currently falls short of lithium-ion standards, though research continues to improve durability.

Industry progress:

- Sion Power is one of the leaders, with its Licerion® lithium-sulfur battery showing promising lab results and initial commercial testing.

- Academic institutions and startups worldwide are actively developing sulfur cathode coatings and electrolyte additives to stabilize performance.

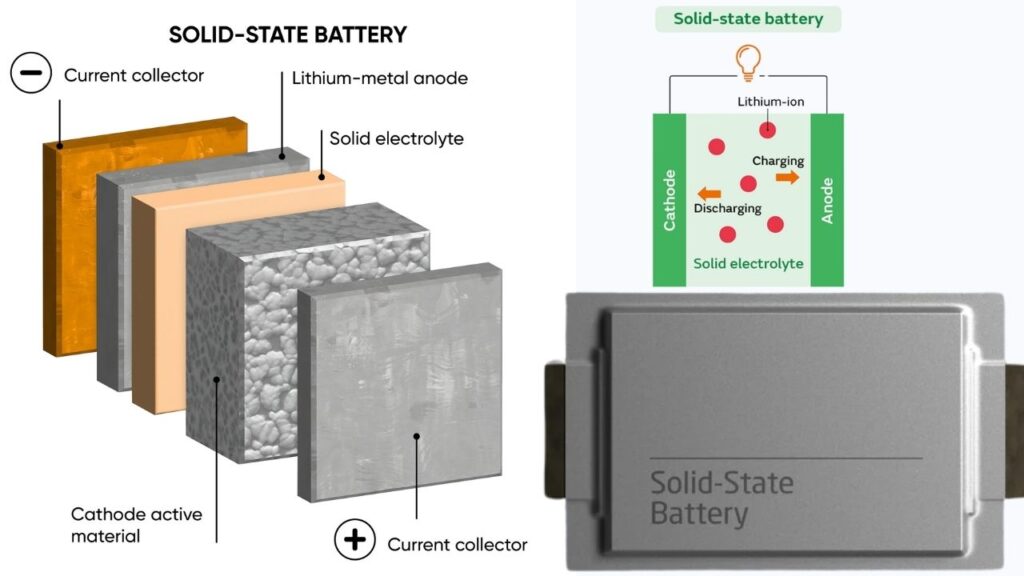

Solid-State Batteries: Safer and More Compact

Solid-state batteries replace the liquid electrolyte found in traditional batteries with a solid electrolyte. This design improves safety and energy density.

Advantages:

- Safety: Solid electrolytes are non-flammable, reducing fire risks.

- Energy density: Can exceed 400 Wh/kg with compact designs.

- Longer lifespan: Reduced degradation leads to longer battery life.

- Simplified design: Anode-free or lithium-metal anodes increase capacity.

Challenges:

- Manufacturing complexity and cost remain barriers.

- Solid electrolytes need to maintain good conductivity and interface stability over many cycles.

Industry progress:

- QuantumScape, backed by Volkswagen, has demonstrated solid-state cells with fast charging and high energy density.

- Nissan aims to bring solid-state batteries to market by 2028–2029 for passenger EVs.

Emerging Chemistries: Magnesium-Sulfur and Potassium-Ion

Other novel chemistries are in early research phases but offer intriguing prospects:

- Magnesium-sulfur batteries: Magnesium’s divalent ions allow for higher charge storage per ion, and magnesium metal anodes are safer than lithium.

- Potassium-ion batteries: Potassium ions have similar charge and discharge properties but are more abundant and cheaper than lithium.

These technologies face challenges with ion mobility and stability but are active areas of academic research.

What Does This Mean for EV Buyers and Industry?

Benefits for EV Consumers

- Lower vehicle cost: Batteries represent 30-40% of EV cost. Reducing lithium can lower purchase prices.

- Improved range: Higher energy density batteries will enable longer drives on a single charge.

- Faster charging: Innovations in battery chemistry and design reduce charging times.

- Enhanced safety: Solid-state and alternative chemistries reduce thermal risks.

Implications for Automakers and Battery Makers

- Supply security: Diversifying materials reduces dependence on lithium and cobalt.

- Sustainability goals: Lower environmental impact aligns with corporate responsibility.

- Competitive advantage: Early adopters of new tech can lead in EV market share.

- Investment in R&D: Significant funding and pilot production are essential to scale these innovations.

Real-World Industry Examples

| Company | Technology | Status and Highlights |

|---|---|---|

| CATL | Sodium-ion | Commercially producing Naxtra cells, powering Chinese EVs |

| Sion Power | Lithium-sulfur | Pilot batteries with >500 Wh/kg energy density, in testing |

| QuantumScape | Solid-state | Prototype cells, backed by VW, aiming for commercial launch by 2028 |

| Faradion | Sodium-ion | Developing affordable, scalable sodium-ion batteries |

| Nissan | Solid-state | Plans mass production by 2028-2029, improving range and safety |

Turning Heat into Power: New Thermoelectric Materials Could Revolutionize Waste Energy Use

Scientists Develop Self-Healing Materials for Electronics and Wearable Devices

Graphene Breakthrough Promises Faster, Smaller, More Efficient Electronics

FAQs About Next-Generation EV Battery Design

Are these lithium-reducing battery technologies widely available today?

- Sodium-ion batteries have started commercial deployment, particularly in China and Europe.

- Lithium-sulfur and solid-state batteries are in pilot and early production phases, with expected commercialization in the late 2020s.

- Magnesium and potassium-based batteries remain mostly in research labs.

How do these new batteries compare to lithium-ion in lifespan?

- Sodium-ion batteries typically offer 2,000+ charge cycles, similar to lithium-ion.

- Lithium-sulfur batteries currently have shorter cycle lives (~300-500 cycles), but improvements are ongoing.

- Solid-state batteries aim for 1,000–2,000 cycles with higher stability.

Will using less lithium compromise battery performance?

- Current technologies are closing the performance gap.

- Sodium-ion batteries are approaching usable energy densities for mid-range EVs.

- Solid-state and lithium-sulfur promise higher energy density and better safety than conventional lithium-ion batteries.

What challenges remain for these new battery types?

- Scaling manufacturing cost-effectively.

- Improving cycle life and stability, especially for lithium-sulfur.

- Developing solid electrolytes with reliable interfaces.