Poland’s coal mining sector is at the forefront of an innovative energy transition, embracing breakthrough technology to address one of the most pressing environmental challenges—methane emissions from coal mines. The METH2GEN project, spearheaded by Jastrzębska Spółka Węglowa (JSW), Europe’s largest coking coal producer, is poised to revolutionize how methane—a potent greenhouse gas—is managed by capturing it underground and converting it to clean hydrogen fuel.

This ambitious project transforms an environmental liability into a valuable energy resource, assisting Poland’s strategy to decarbonize heavy industry and meet stringent European climate targets.

Table of Contents

Polish Mines May Turn Methane Into Hydrogen

| Aspect | Information |

|---|---|

| Project Lead | Jastrzębska Spółka Węglowa (JSW) |

| Location | Budryk Coal Mine, Silesian Voivodeship, Poland |

| Budget | €25.6 million (majority funded by JSW, EU Horizon funds supported) |

| Methane Capture Efficiency | Target: ~70% methane drainage |

| Technologies Used | Directional drilling and Steam Methane Reforming (SMR) with Carbon Capture and Utilization (CCU) |

| Environmental Benefits | Reduces methane emissions; captures CO₂ for mine fire prevention |

| Hydrogen Produced | Blue hydrogen (SMR-derived with CO₂ capture) |

| Cost | Cheaper than electrolytic green hydrogen |

| EU Collaboration | Aligns with EU methane reduction and hydrogen strategies |

| More Info | Official JSW Website |

The METH2GEN project by JSW represents a significant breakthrough in the intersection of traditional coal mining and clean energy innovation. By capturing harmful methane emissions and converting them into cost-effective, low-carbon hydrogen, it addresses safety and environmental challenges while supporting Poland’s industrial decarbonization and energy transition goals.

With robust technology, EU collaboration, and strong financial backing, METH2GEN could serve as a global blueprint for coal-dependent regions looking to reduce greenhouse gases without compromising economic stability. This initiative demonstrates that smart, integrative solutions can generate clean energy while mitigating the environmental legacy of fossil fuel industries.

For those eager to follow Poland’s pioneering steps toward a sustainable energy future or interested in advanced methane capture methods, METH2GEN provides a compelling, actionable model.

Why Is Methane from Coal Mines Such a Big Deal?

Methane (CH₄) is a natural gas trapped within coal seams. During mining operations, methane escapes into the atmosphere unless properly captured and controlled. Its importance and risks stem from two main factors:

- Environmental Impact: Methane has a global warming potential approximately 28 to 36 times greater than carbon dioxide (CO₂) over a 100-year timeframe, as reported by the Intergovernmental Panel on Climate Change (IPCC, AR6, 2021). This makes it a far more potent driver of climate change when released untreated.

- Mine Safety Hazard: Methane is highly explosive when mixed with air in concentrations between 5% and 15%, posing catastrophic risks in underground mines.

Historically, many coal mines have either released methane directly into the atmosphere or flared it — burning it off to reduce its climate impact but losing the chance to use it as fuel. Capturing this “waste” methane not only improves safety and cuts emissions but opens pathways for clean energy production.

The METH2GEN Project: Converting Methane to Hydrogen

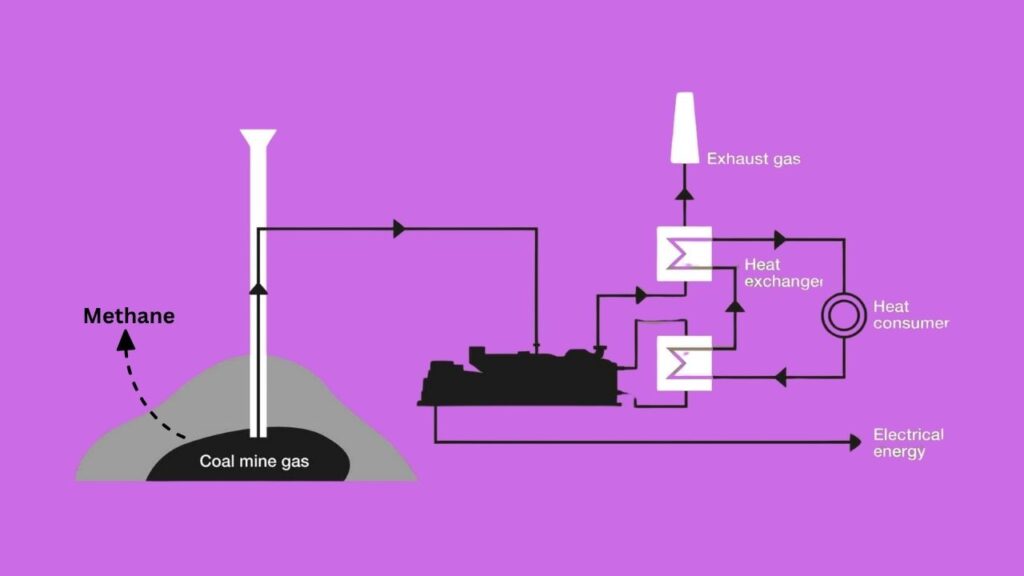

The METH2GEN initiative combines cutting-edge directional drilling and Steam Methane Reforming (SMR) technologies with carbon capture, enabling JSW to capture roughly 70% of methane emissions from active mining zones and convert it into blue hydrogen—a low-carbon fuel still underpinned by fossil methane but with much lower net emissions thanks to CO₂ sequestration.

Step-By-Step: How Does the METH2GEN Project Work?

1. Methane Capture Using Directional Drilling

Methane in mining areas is not uniformly distributed. To efficiently extract and capture this gas, directional drilling — precision drilling that reaches target zones at specific angles — is deployed. This approach allows wells to tap methane pockets deep around the mine longwalls, where mining activity is most intense.

Directional drilling enables recovering more methane than conventional vertical wells, especially from difficult-to-reach seams close to active mining zones.

— Source: International Energy Agency (IEA) Methane Guidelines, 2023

2. Converting Methane to Hydrogen with Steam Methane Reforming (SMR)

In the SMR process, methane is reacted with steam under high temperatures (700–1,000°C) in the presence of a catalyst, producing a mix of hydrogen and carbon monoxide. This is further converted to hydrogen and CO₂ in a secondary shift reaction.

The resulting hydrogen is a clean, versatile fuel, while the CO₂ is captured and diverted for practical use within the mine—such as fire prevention, an innovative CO₂ utilization strategy that prevents dangerous underground fires while limiting emissions.

The blue hydrogen produced by this process is currently a cost-effective and practical low-carbon option, especially compared to green hydrogen, which relies on renewable-powered electrolysis but remains more expensive and less established at scale.

— Source: Hydrogen Council Report, 2024

3. CO₂ Capture and Utilization (CCU)

Unlike traditional SMR that releases CO₂ into the atmosphere, METH2GEN incorporates carbon capture technology that traps CO₂ by-products and repurposes them underground. This reduces the carbon footprint substantially, improving the environmental credentials of the hydrogen produced.

Why Is Hydrogen Important for Poland’s Energy Future?

Hydrogen is rapidly becoming a cornerstone in global decarbonization efforts. Its benefits include:

- Zero Carbon Emissions at Use: Hydrogen fuel emits only water vapor when used in fuel cells or combustion.

- Industrial Applications: Key for steel production, chemical manufacturing, and heavy transport—sectors difficult to electrify.

- Energy Storage and Grid Balancing: Can store surplus renewable energy and stabilize grids.

- Economic Growth: Fostering hydrogen industries can create jobs, innovation, and help Poland transition from coal dependence.

Poland’s industrial landscape—currently reliant on coal—requires scalable, affordable hydrogen solutions. Projects like METH2GEN provide an economically competitive hydrogen supply while addressing legacy methane problems.

Environmental and Economic Impacts

Environmental

- Methane Emissions Reduction: Capturing 70% of methane from Budryk mine alone cuts a substantial portion of JSW’s total greenhouse emissions, advancing national and EU methane reduction targets.

- CO₂ Emissions Mitigation: Carbon capture and utilization lowers SMR’s footprint, making the hydrogen significantly cleaner.

- Improved Mine Safety: Reducing methane concentration underground minimizes explosion risks, protecting miners and infrastructure.

Economic

- Operational Cost Efficiency: SMR with captured methane is cheaper than electrolytic hydrogen, enabling industrial consumers to switch at a manageable cost.

- Funding and EU Support: The €25.6 million project receives partial funding from the European Union’s climate innovation programs, underscoring EU commitment to methane mitigation.

- Industrial Competitiveness: Domestic hydrogen production creates energy security and supports Poland’s industrial transformation.

Breakthrough Turns Sugarcane Waste Into Clean Hydrogen — With Almost Zero Emissions

Engineered Ruthenium Catalysts: A Sustainable Revolution for Hydrogen and Ammonia

Monash Breakthrough Paves the Way for Cheap, Large-Scale Green Hydrogen

FAQs About Polish Mines May Turn Methane Into Hydrogen

Q1: How significant is methane as a greenhouse gas compared to CO₂?

Methane is roughly 28–36 times more potent than CO₂ over a century. However, it has a shorter atmospheric lifespan (about 12 years) compared to CO₂, so reducing methane emissions has rapid climate benefits.

— Source: IPCC AR6, 2021

Q2: Why is blue hydrogen seen as a practical option right now?

Blue hydrogen leverages existing natural gas infrastructure and SMR technology with carbon capture, allowing large-scale, cost-effective hydrogen production while reducing emissions, bridging toward a future dominated by green hydrogen.

— Source: Hydrogen Council Report, 2024

Q3: Could this technology be replicated in other mining regions?

Yes. Any coal mining region with methane emissions can potentially apply directional drilling and methane-to-hydrogen conversion technology, especially where hydrogen demand is growing.

Q4: What are the safety benefits for miners?

Methane is explosive when mixed with air at concentrations between 5-15%. Enhanced methane capture reduces underground gas concentrations, significantly lowering explosion risk.

Q5: How does EU policy support this project?

The EU’s methane strategy targets a 30% reduction in methane emissions by 2030 (compared to 2020 levels) and promotes clean hydrogen development via its Fit for 55 and Hydrogen Strategy initiatives, aligning with METH2GEN’s goals.