Recycling Electronics with Light: In today’s tech-driven world, electronic waste (e-waste) is growing faster than any other waste stream. From old smartphones to obsolete laptops, electronic gadgets are being discarded at an alarming rate. But what if we could recycle electronics using light? That’s exactly what laser-assisted material recovery is all about. This cutting-edge technique is helping scientists and engineers recover valuable materials like gold, copper, and rare earth elements—without harmful chemicals or massive energy costs.

Whether you’re a curious reader, a recycling professional, or a sustainability advocate, this guide will walk you through how laser technology is transforming e-waste recycling, why it matters, and how it can impact industries and the environment alike.

Table of Contents

Recycling Electronics with Light

| Topic | Details |

|---|---|

| Main Focus | Laser-assisted material recovery in e-waste recycling |

| Key Materials Recovered | Gold, copper, tantalum, neodymium, gallium, cobalt |

| Technology Used | Laser ablation, electric field-assisted recovery, robotics |

| Major Project Example | ADIR Project by Fraunhofer Institute |

| Environmental Benefit | Reduces chemical use, improves material purity |

| Global Impact | Addresses 59.4 million tons of global e-waste (as of 2022) |

| Who Should Care? | Environmental scientists, electronics manufacturers, recycling companies, tech consumers |

| Official Source | Fraunhofer Institute for Laser Technology |

Recycling electronics with light isn’t just a futuristic idea—it’s a practical solution that’s already proving its value. With laser-assisted material recovery, we can make electronic waste recycling faster, cleaner, and far more efficient. It’s an innovation that benefits not just the planet, but also businesses, manufacturers, and consumers.

As more countries embrace this technology, we’re looking at a future where your old smartphone could power the next generation of devices—not rot in a landfill.

Why Traditional E-Waste Recycling Falls Short

Traditional e-waste recycling often involves shredding devices and using chemical treatments to extract metals. This approach is not only energy-intensive, but also risks polluting the environment and damaging recoverable components.

According to the Global E-waste Monitor 2024, over 59.4 million metric tons of e-waste were generated worldwide, but only 17.4% was officially documented as properly collected and recycled. That means millions of devices are either sitting in landfills or improperly processed—leaking toxic substances like lead and mercury into the soil and water.

That’s where laser-assisted recycling comes in.

What Is Laser-Assisted Material Recovery?

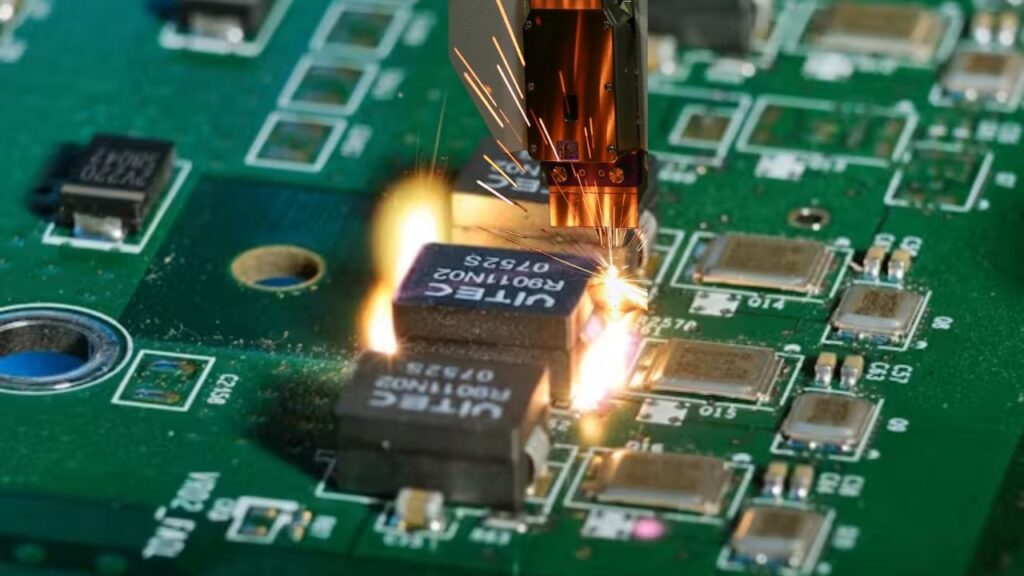

Laser-assisted material recovery uses precision lasers to identify, isolate, and extract valuable materials from old electronics. Think of it as surgery for your smartphone—clean, accurate, and controlled.

How It Works

- Scanning: A laser scans the surface of a device to identify materials.

- Targeting: It pinpoints valuable components like gold wires or copper traces.

- Extraction: Using laser pulses or ablation, it removes specific materials without damaging surrounding parts.

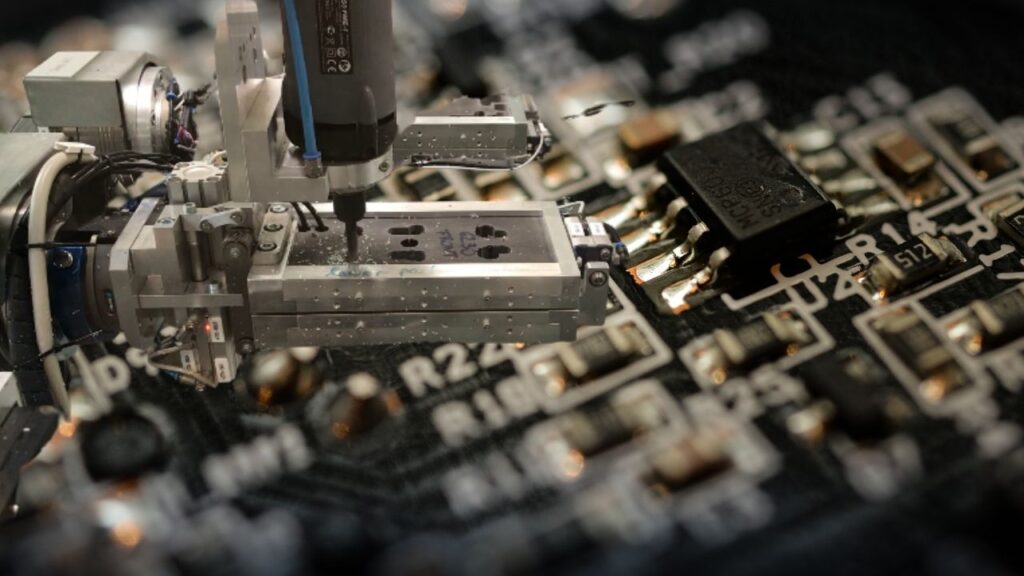

- Sorting: Robotics and AI sort components for further use or processing.

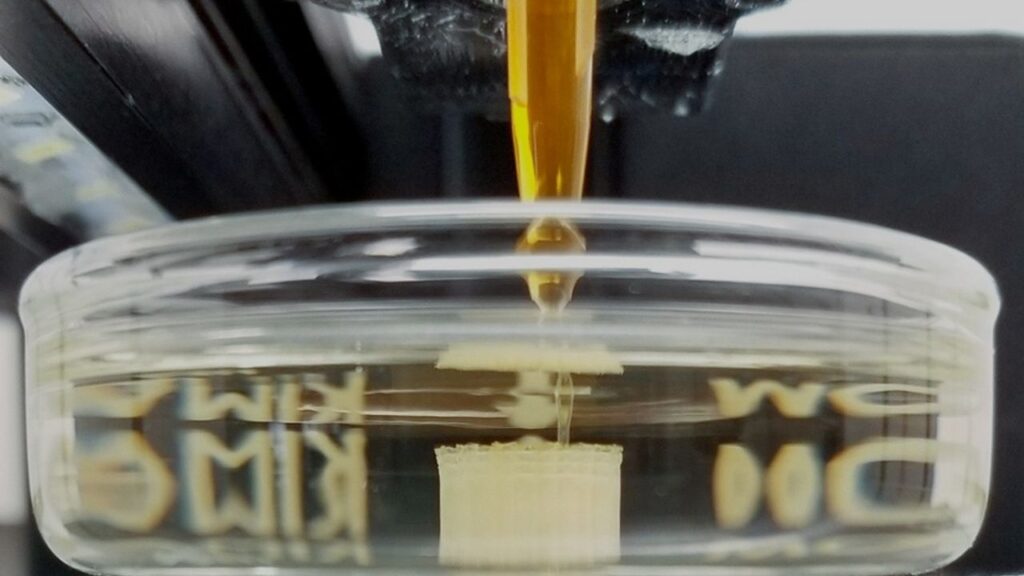

One of the most promising techniques includes laser ablation in liquids, where the device is submerged in a liquid, and a laser vaporizes the target metal, making recovery cleaner and safer.

The ADIR Project: A Real-World Example

The ADIR (Next Generation Urban Mining) project, led by the Fraunhofer Institute for Laser Technology in Germany, is a game-changing initiative in this field.

What They Did

- Disassembled 1,000 mobile phones and 800 PCBs (Printed Circuit Boards) using automated systems.

- Used laser optics, robotics, and AI algorithms for precise extraction.

- Recovered rare and valuable materials like tantalum, neodymium, gallium, and cobalt.

- Achieved higher material purity than traditional chemical-based methods.

This approach, often called “inverse production”, flips traditional manufacturing by focusing on disassembly and recovery, rather than assembly and disposal.

Why This Matters: Environmental and Economic Benefits

Environmental Impact

- No toxic chemicals like cyanide or nitric acid.

- Reduces carbon footprint of recycling.

- Minimizes landfill waste and pollution.

Economic Incentives

- Gold recovery from e-waste can yield 300–400 grams per ton, compared to 1–5 grams per ton from mined ore.

- Increases cost-efficiency through automation.

- Supports a circular economy—reusing materials instead of extracting new ones.

Urban mining, or extracting materials from e-waste, could soon rival traditional mining in value and sustainability.

Step-by-Step Guide: How Laser-Based Recycling Works

Step 1: Identification

High-speed cameras and sensors scan the electronic device. Software identifies components like chips, capacitors, and circuits.

Step 2: Laser Mapping

Lasers map out a disassembly path. This ensures minimal damage and maximum recovery.

Step 3: Precision Extraction

Lasers remove solder, cut casings, or vaporize unwanted materials. Valuable metals are collected separately.

Step 4: Robotic Sorting

AI-powered robots sort and classify parts. Reusable components go one way; recyclable materials go another.

Step 5: Material Recovery

Metals are extracted for reuse. Plastic and glass components are separated for recycling or disposal.

Applications and Future Potential

Laser-assisted recycling isn’t just for smartphones. It’s being expanded to:

- Electric vehicle batteries (retrieving lithium and cobalt)

- Solar panels (recovering silicon and rare earths)

- Medical electronics (safe disassembly of complex systems)

Emerging Technologies

- Electric field-assisted laser ablation: Adds a field to guide materials out more efficiently

- AI-integrated systems: Learning-based systems that optimize laser parameters in real-time

Challenges and Limitations

High Initial Investment

The cost of setting up laser recycling facilities is high due to advanced hardware and system integration.

Scalability

While promising, most laser recycling projects are still in pilot stages and need significant scaling to compete with mass chemical recycling.

Skilled Workforce

Technicians and engineers must be specially trained to manage and maintain laser-based systems.

Career Opportunities in Laser Recycling

As this field grows, so do job opportunities in:

- Laser optics and photonics

- Mechatronics and robotics

- Environmental engineering

- Data analysis and AI systems

Universities and technical institutes are beginning to offer training programs focused on green electronics and advanced recycling methods.

The Rise of Wearable Technology: Materials That Make Smart Clothing Possible

LED Innovations: The Bright Future of Energy-Efficient Lighting

Photonics in Space: How NASA Is Using Laser Communication to Boost Deep-Space Data Transfer

FAQs About Recycling Electronics with Light

Is laser-assisted recycling safe?

Yes. It reduces the need for harmful chemicals and is generally safer for both workers and the environment.

How much material can be recovered from a phone?

A typical smartphone can contain 0.034g of gold, 0.35g of silver, 15g of copper, and rare earth metals like tantalum and neodymium.

Can laser recycling be done at home?

No. It requires specialized equipment and is best handled in industrial or lab settings.

Is it expensive to set up laser-based recycling?

The initial investment is high due to advanced technology, but automation reduces long-term labor costs, making it cost-effective over time.

Are there other companies or countries doing this?

Yes. Japan, South Korea, and the EU are investing heavily in laser and robotics-based recycling for national e-waste strategies.