3D printing technology is evolving fast, and a revolutionary resin mix now enables unmatched precision and versatility by using different light wavelengths to control how materials harden and behave in a single print. This breakthrough technology means multi-material objects can be printed in one seamless step, with strong bonds between different zones and improved efficiency.

This article explains how this wavelength-controlled resin 3D printing works, its real-world applications, the latest innovations, and what it promises for the future of manufacturing and design—all in clear, approachable language for both curious beginners and seasoned professionals.

Table of Contents

Breakthrough Resin Mix Unlocks Next-Gen 3D Printing With Wavelength Precision

| Feature | Details |

|---|---|

| Technology | Dual or multi-wavelength photopolymerization 3D printing with specially formulated resins |

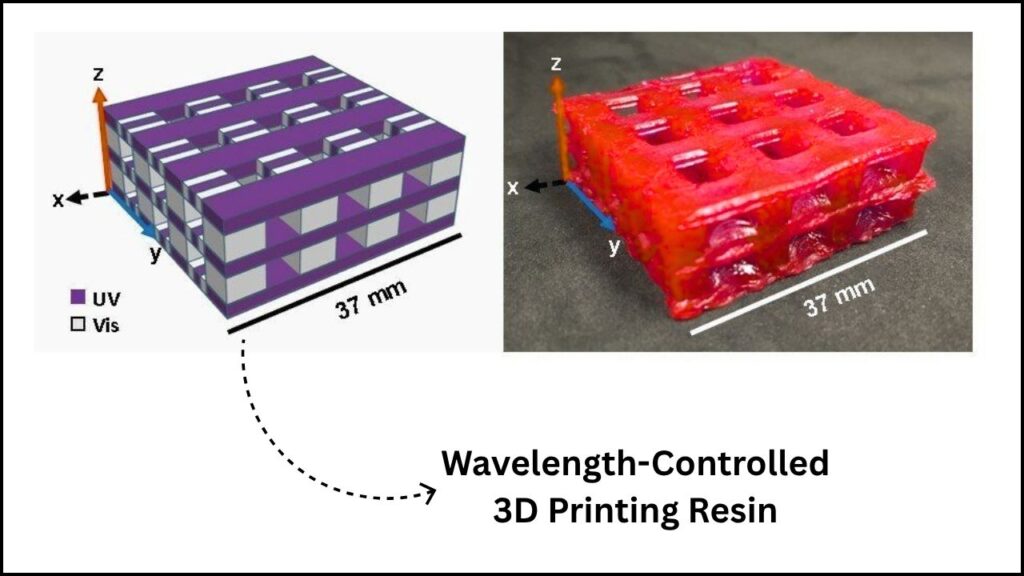

| How it works | Ultraviolet (UV) light cures rigid, permanent materials; visible/violet/near-infrared (NIR) light cures flexible, dissolvable, or self-healing polymers |

| Printing speed | Up to 22.5 mm per hour with fine feature resolution (~20 microns) |

| Material versatility | Single resin creates both permanent and dissolvable parts or hard and flexible regions within the same print |

| Applications | Medical implants, hearing aids, robotic components, flexible electronics, complex support structures |

| Benefits | – True multi-material printing in a single step – Strong, durable interfaces – Streamlined post-processing – Design freedom and material efficiency |

| Ongoing challenges | Longer-term resin stability, expanding wavelength-responsive chemistries, commercial scaling |

| Official resource | MIT News on Multi-Material Wavelength-Controlled 3D Printing |

The breakthrough wavelength-controlled resin 3D printing is set to transform additive manufacturing by enabling multi-material, high-precision, and efficient printing in a single step. By harnessing special resins that react differently to UV and visible or NIR light, complex and functional parts can be made with strong, seamless interfaces, opening new frontiers in healthcare, robotics, electronics, and beyond.

Ongoing research aims to refine resin chemistry, expand wavelength options, and scale production to bring these advantages into everyday manufacturing and prototyping workflows.

What Is Wavelength-Controlled 3D Printing Resin?

Traditional vat photopolymerization 3D printers use a single wavelength of light, most commonly ultraviolet (UV), to harden a resin layer by layer into a solid object. This means you can only print one material type per print, often requiring manual assembly for multi-material designs or painstaking removal of support structures.

The new wavelength-controlled resins respond differently depending on the light wavelength they absorb:

- UV light (~365 nm) cures the resin into a durable, rigid polymer network.

- Visible or violet light (~400–450 nm) cures softer, flexible, or even dissolvable polymer materials.

- Some resins even respond to near-infrared (NIR) light (~780 nm), which can rapidly cure thick or optically challenging layers with less light scattering.

By shining different wavelengths onto different parts of the print during one session, you can create an object with varied mechanical properties and material types all at once—without changing the resin batch or stopping the printer.

Why Is This a Game-Changer for 3D Printing?

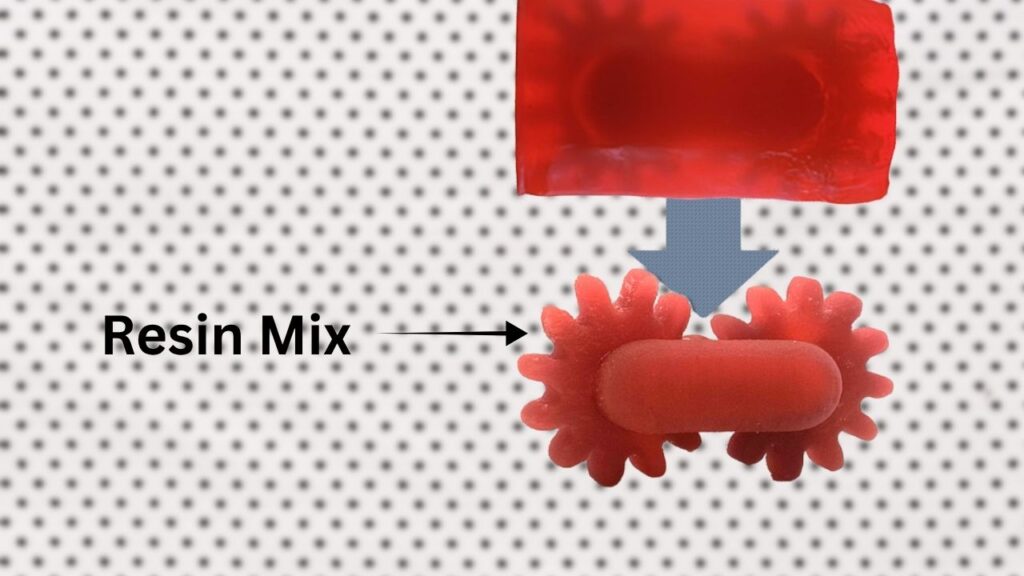

1. True Multi-Material Printing in a Single Step

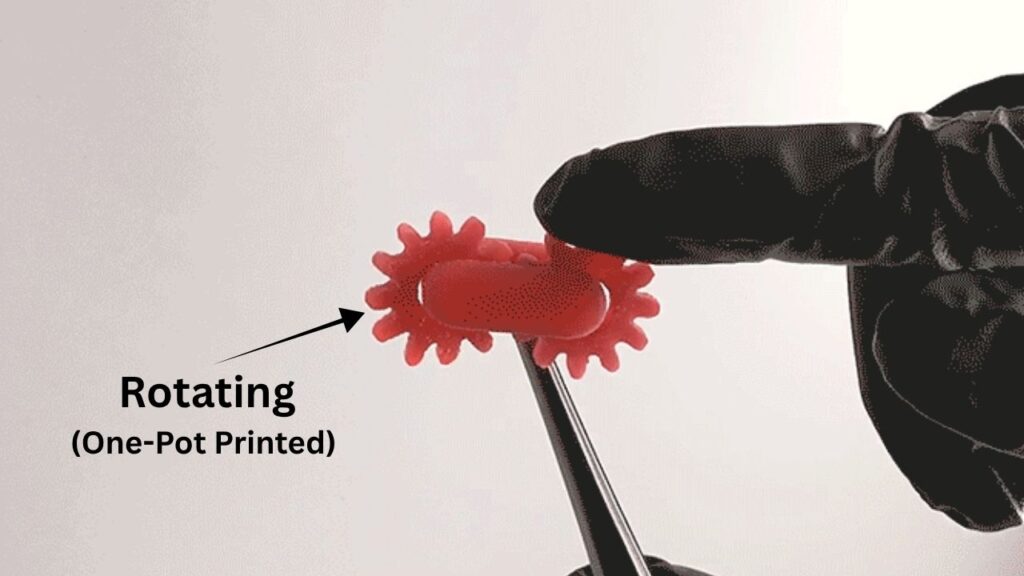

Until now, printing multiple materials meant printing each separately or manually assembling parts. These new resins allow one-pot printing: areas exposed to UV light form hard, structural elements, while visible or NIR light cures flexible, soft, or removable zones. This results in seamlessly integrated parts with no manual bonding or assembly needed.

For example, MIT engineers printed objects that combine rigid UV-cured frames with visible-light-cured dissolvable supports, which simply wash away after printing—eliminating manual support removal and speeding production.

2. Stronger Interfaces Between Materials

A common issue with multi-material printing is weak interfaces where different materials meet, causing cracks or delamination under stress. The molecules in these new resins include specially designed “bridging” monomers that chemically connect the hard and soft polymer networks. This makes the interfaces strong, durable, and able to withstand mechanical stresses a fully integrated piece would.

3. Faster, More Efficient Printing

These advanced resins cure rapidly—some formulations can solidify a layer in as little as 60 seconds—with detailed features as fine as 20 microns, which is visible under a microscope but invisible to the naked eye. Visible-light activated resins support printing speeds up to 22.5 mm per hour without sacrificing precision.

4. New Possibilities for Innovative Products

This technology enables a whole new class of products with mixed material properties printed directly, such as:

- Medical devices refined for comfort and strength, like hearing aids and dental implants with soft and rigid zones.

- Soft robots and flexible electronics combining stretchable and solid parts.

- Complex assemblies with moving parts printed as one piece.

- Self-healing and optically clear materials through fine-tuned resin chemistry.

How to Use Wavelength-Responsive Resin 3D Printing: A Practical Guide

For professionals and enthusiasts interested in applying this breakthrough, here’s a step-by-step overview:

Step 1: Select the Right Resin

Choose dual- or multi-wavelength sensitive resins that contain chemically compatible monomers activated by UV and visible/NIR light. Some formulations combine epoxy and acrylate monomers to produce permanent and dissolvable parts simultaneously.

Step 2: Use a Compatible Multi-Wavelength Printer

Use a 3D printer equipped with light sources (LED or laser) capable of emitting multiple wavelengths — either switchable rapidly or simultaneously directed in patterns. Precise control over light intensity and timing is essential for successful multi-material curing.

Step 3: Design Your Model with Material Zones

In your CAD software, assign different parts of your design to different material types based on function — for example, hard support frames versus flexible hinges. Specify which wavelength cures each zone according to resin behavior.

Step 4: Optimize Exposure Settings

Fine-tune light intensity and exposure times for each wavelength to ensure complete curing without cross-contamination. Correct balance avoids weak spots from underexposure or excessive crosslinking that damages flexibility.

Step 5: Post-Processing

For resins with dissolvable components, immerse your printed object in a compatible solvent that dissolves the support material leaving the final sturdy object intact. This simplifies cleanup while reducing waste and harmful manual labor.

Important Data & Insights

- Resolution: Achieves features around 20 microns (approximately size of a human hair’s thickness).

- Material Properties: UV-cured parts match consumer-grade plastics in strength; visible-light cured parts can stretch and bounce like rubber bands.

- Print Speed: Capable of up to 22.5 mm per hour, which is competitive among photopolymerization methods.

- Environmental Benefits: Dissolvable supports reduce plastic waste and eliminate manual post-processing.

- Research and Development: Actively advanced by leading research institutions such as MIT, supported by government agencies.

Scientists Encode Multiple Properties Into a Single Material Using 3D Printing Magic

Shocking New Trends Are Redefining 3D Printing Filaments in 2025

Game-Changing 3D Printing Breakthrough Lets Scientists Combine Multiple Materials in One Build

FAQs About Breakthrough Resin Mix Unlocks Next-Gen 3D Printing With Wavelength Precision

Q1: Can my existing 3D printer use wavelength-controlled resin?

Most currently installed 3D printers need hardware upgrades to emit multiple wavelengths, typically by adding multi-color LEDs or lasers and updated control software.

Q2: Are these resins safe and environmentally friendly?

New formulations aim to minimize toxic substances; dissolvable supports reduce waste. However, solvents used for support removal require safe handling and disposal.

Q3: What kinds of materials can be printed?

The technology allows printing rigid plastics, flexible elastomers, dissolvable supports, and even self-healing or optically clear materials.

Q4: Does mixing wavelengths affect print quality?

Yes, maintaining precise control over timing, intensity, and chemistry is critical to prevent undesired curing and ensure clean boundaries between materials.

Q5: Is this technology commercially available?

Some wavelength-sensitive resins and multi-wavelength printers are available on the market, but many innovations remain at research or pilot production stages.