Reticular Materials Commercialized: If you’ve been paying attention to the latest buzz in clean tech, you’ve probably heard the term reticular materials thrown around. Maybe it sounds like something out of a sci-fi flick, but trust me, these high-tech materials are already making waves right here in the USA.

From carbon capture to water generation, gas storage, and even chemical protection, reticular materials are quietly powering some of the most exciting green innovations of our time.

Let’s break it down in plain English, with a dash of American spirit, some real talk, and plenty of practical advice—so whether you’re a curious kid or a seasoned engineer, you’ll walk away knowing exactly why these materials matter.

Reticular Materials Commercialized

| Feature | Details | Key Data/Stats | Career/Professional Info |

|---|---|---|---|

| What are Reticular Materials? | Highly porous, customizable frameworks (MOFs, COFs, ZIFs) | Can store up to 10x more gas than traditional materials | Used by chemical, energy, and water industries |

| Carbon Capture | Capture CO₂ from air or exhaust using MOFs | Companies like BASF, Atoco, Nuada lead the field | Careers: Clean energy, chemical engineering |

| Water Generation | Extracts water from air, even in deserts | Air Joule & Atoco commercialize for arid regions | Careers: Water tech, sustainability |

| Gas Storage | Stores hydrogen, methane, and other gases safely and efficiently | MOFs exceed US Dept. of Energy targets for methane storage | Careers: Energy storage, materials science |

| Chemical Protection | Filters toxins, chemicals, and even chemical warfare agents | Used in PPE, masks, and industrial filters | Careers: Safety engineering, defense tech |

| Industrial Formats | Available as pellets, films, foams, monoliths for different uses | Structured for durability and performance under tough conditions | Manufacturing, product design |

Reticular materials are changing the way we tackle some of America’s biggest challenges—from keeping our air clean and our water flowing, to storing clean fuels and protecting our workers. With their unique properties and growing commercial use, these materials are powering a new wave of innovation that’s good for business, good for the planet, and good for the next generation.

Whether you’re a student, a professional, or just someone who cares about the future, now’s the time to pay attention to this game-changing technology. The next big breakthrough could be just around the corner—and it might just come from a reticular material.

What Are Reticular Materials? (And Why Should You Care?)

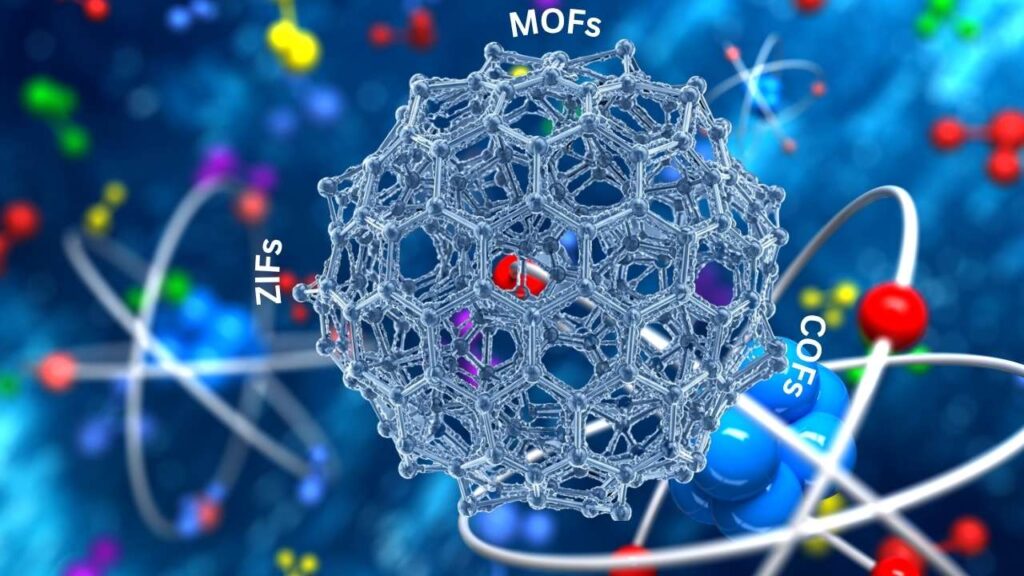

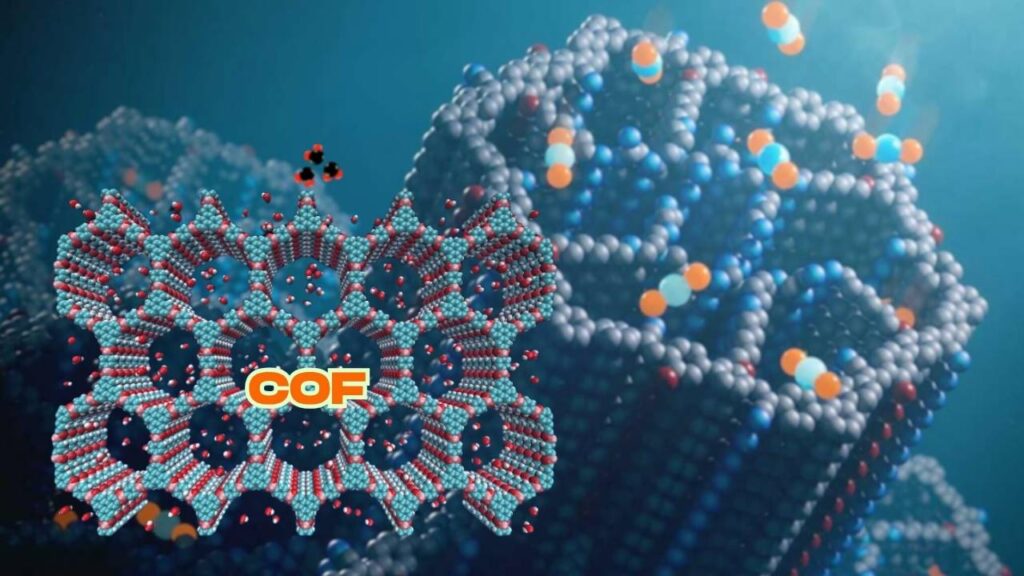

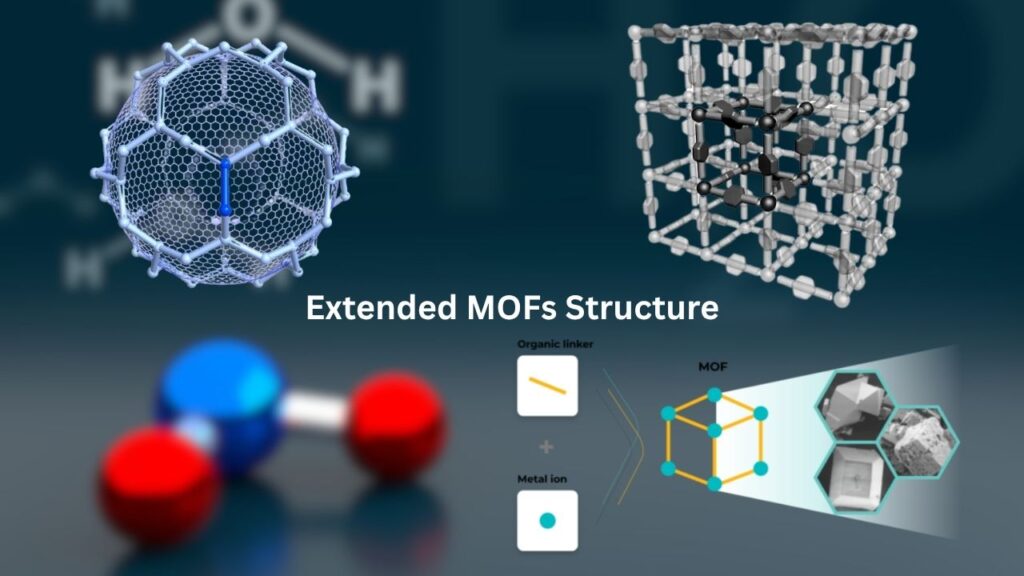

Let’s kick things off with the basics. Reticular materials are a family of super-porous, customizable solids. The most famous members are metal-organic frameworks (MOFs), covalent organic frameworks (COFs), and zeolitic imidazolate frameworks (ZIFs). Think of them like molecular sponges—only way smarter and a whole lot tougher.

These materials are built by snapping together tiny building blocks (think: LEGO, but at the atomic level) to create a framework full of holes, or pores. These pores are the secret sauce, letting reticular materials trap, store, or filter all sorts of molecules—gases, water, chemicals, you name it.

Why All the Hype?

- Customizable: Scientists can tweak the size and shape of the pores for specific jobs.

- Super Porous: A single gram can have the surface area of a football field.

- Strong & Stable: They survive tough industrial conditions without falling apart.

How Reticular Materials Are Changing the Game

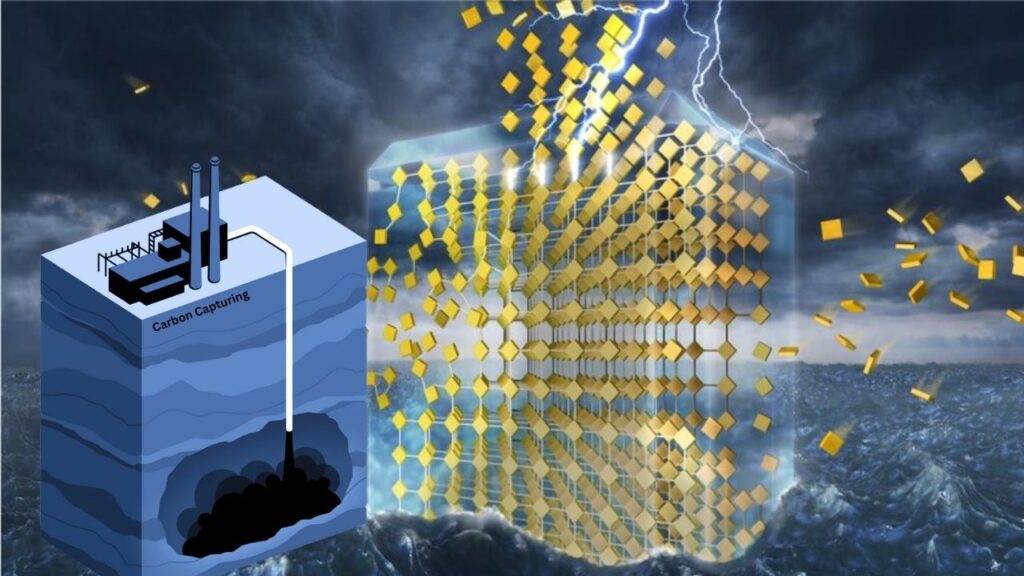

Carbon Capture: Cleaning Up Our Air

Carbon capture is a hot topic these days, and for good reason. The U.S. pumps out over 5 billion metric tons of CO₂ every year. Reticular materials are stepping in as the MVPs of this fight, thanks to their ability to trap carbon dioxide right out of the air or exhaust pipes.

Real-World Example

- BASF, Atoco, and Nuada are rolling out MOF-based filters that can grab CO₂ before it escapes into the atmosphere. These systems are used in factories, power plants, and even direct air capture (DAC) machines that suck CO₂ straight from the sky.

- These filters are so efficient, they can reduce the cost of carbon capture by up to 30% compared to old-school methods.

Pro Tip

If you’re in chemical engineering or environmental science, learning about MOF-based carbon capture could land you a job in one of the fastest-growing green tech sectors.

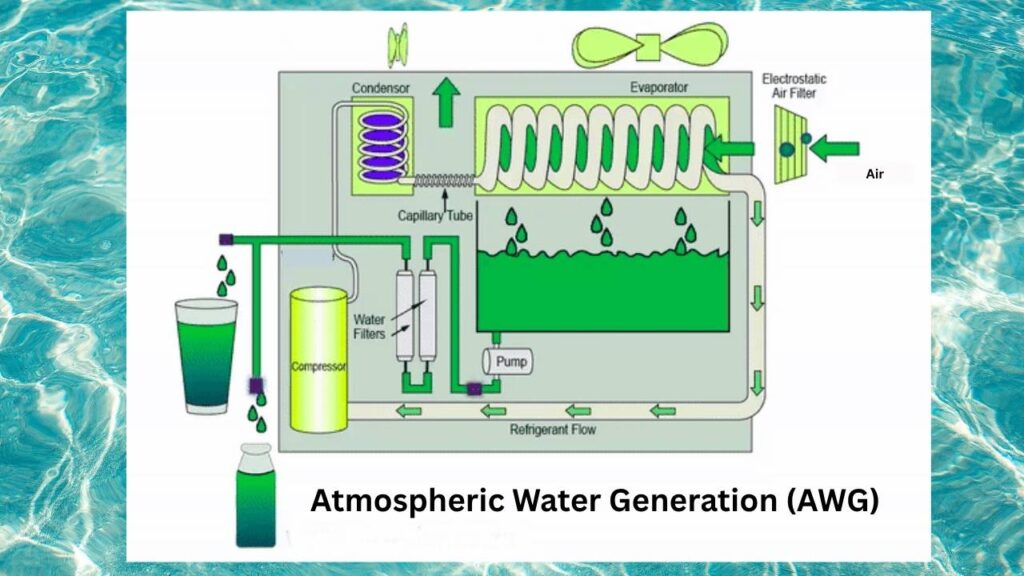

Water Generation: Pulling Water Out of Thin Air

It sounds like magic, but atmospheric water generation (AWG) is real science. Reticular materials can soak up water vapor from the air—even in deserts—and release it as pure, drinkable water.

Who’s Doing It?

- Air Joule and Atoco are commercializing these systems for use in drought-prone areas and military operations.

- These devices are already providing clean water in places where wells and rivers just aren’t an option.

Fun Fact

A single MOF-based water harvester can produce several liters of water per day from desert air, using nothing but sunlight to power the process.

Gas Storage: Fueling the Future

Hydrogen cars, natural gas buses, and even backup power plants all need safe, efficient ways to store gases. Reticular materials are crushing it here, too.

How It Works

- MOFs can store up to 10 times more hydrogen or methane than traditional tanks, thanks to their massive internal surface area.

- The U.S. Department of Energy set tough targets for methane storage. MOF-based systems have already blown past those goals, making them a top pick for next-gen fuel storage.

Who’s Hiring?

Energy companies, car makers, and aerospace firms are all looking for folks who understand these new storage technologies. If you’re into chemistry, physics, or engineering, this field is wide open.

Chemical Protection: Safety First

From firefighters to factory workers, chemical protection is a must. Reticular materials are now used in advanced filters for masks, air purifiers, and even military gear.

What Makes Them Special?

- They can trap not just dust and smoke, but also toxic chemicals and even nerve agents.

- Companies like Numat and Tetramer are leading the charge, making filters that keep first responders and soldiers safe on the job.

Career Angle

If you’re interested in safety engineering or defense tech, understanding how these filters work could give you a serious edge.

How Are Reticular Materials Made and Used?

From Lab to Factory Floor

The journey from a scientist’s beaker to a factory or water plant isn’t easy. Reticular materials need to be structured and shaped for real-world use—think pellets, films, foams, or even monoliths (big, solid chunks).

Key Steps

- Design: Scientists choose the right building blocks for the job (e.g., capturing CO₂, storing hydrogen).

- Synthesis: The frameworks are built using chemical reactions.

- Shaping: The material is formed into a usable shape—pellets for filters, films for sensors, etc.

- Testing: Each batch is tested for durability, efficiency, and safety.

- Deployment: The final product is installed in a power plant, water generator, or protective gear.

Industrial Scale

The biggest challenge? Scaling up production while keeping the material’s special properties intact. But thanks to advances in manufacturing, American companies are now producing reticular materials by the ton.

Satellite LiDAR and AI Enable Rapid Forest Carbon Mapping Breakthrough

Researchers Develop Metallic Materials Using Data-Driven Frameworks and Explainable AI

FAQs About Reticular Materials Commercialized

What are reticular materials made of?

Reticular materials are built from metal ions (like zinc or copper) and organic molecules, snapped together to form a solid with lots of tiny holes.

Are these materials safe?

Yes! They’re designed to be stable, non-toxic, and tough enough for industrial use. Most are already approved for use in water, air, and safety applications.

How much do they cost?

Prices are dropping fast as production scales up. While still pricier than some old-school materials, their efficiency often means you need less of them to do the same job—saving money in the long run.

Where can I learn more or get involved?

Check out the Key Highlights table above for a great starting point.

Are there jobs in this field?

Absolutely! From research and development to manufacturing, sales, and environmental policy, there are tons of opportunities for folks who want to make a difference.