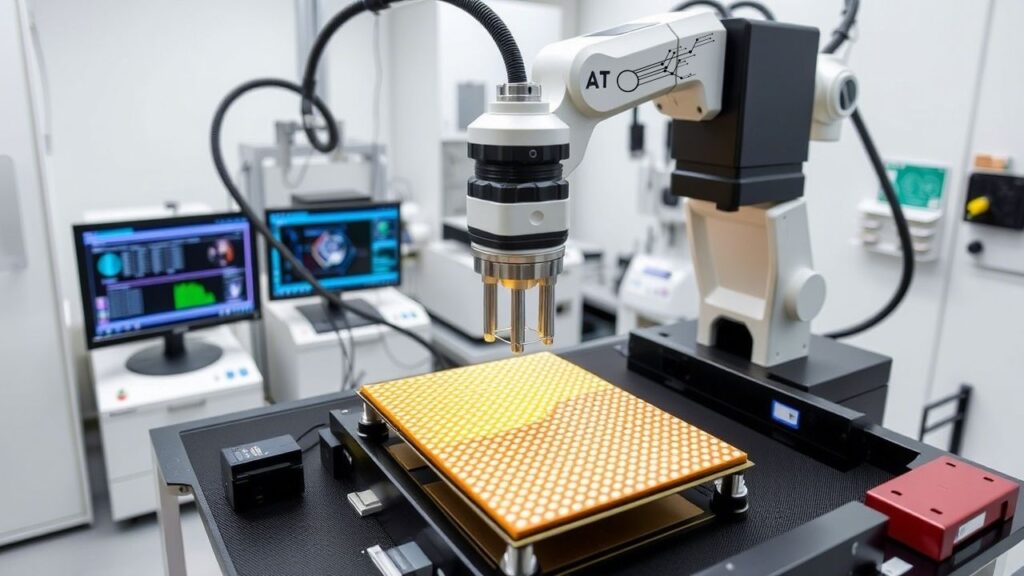

Robotic Automation Enhances Scalability of 2D Materials for Electronic Devices: Two-dimensional (2D) materials like graphene, molybdenum disulfide, and other atomically thin crystals have opened exciting possibilities for the future of electronic devices. However, scaling up these materials from the lab to industry has long been a challenge. Today, robotic automation is revolutionizing this process by enhancing the scalability, quality, and efficiency of manufacturing 2D materials for electronic applications.

In this article, we will explore how robotic automation improves the scalability of 2D materials in electronic devices. You’ll get clear explanations, practical insights, and reliable data to understand why this is a game-changer for the electronics industry, from flexible displays to sensors and beyond.

Table of Contents

Robotic Automation Enhances Scalability of 2D Materials for Electronic Devices

| Topic | Details |

|---|---|

| What Are 2D Materials? | Atomically thin materials like graphene, offering extraordinary electronic, optical, and mechanical properties |

| Role of Robotic Automation | Precise handling, assembly, and cleaning of 2D materials for scalable manufacturing |

| Scalability Impact | Robotic systems can process up to 180 wafers/day with high-quality performance |

| Performance Gains | Graphene carrier mobility exceeding 14,000 cm²/V·s indicating excellent electrical conductivity |

| Industrial Applications | Flexible electronics, photonics, sensors, and high-performance transistors |

| Future Outlook | Integration of AI and machine learning to optimize production and discovery |

Robotic automation is redefining the scalability of 2D materials for electronic devices. By automating delicate handling, precise assembly, and ensuring clean interfaces, robotics enables high-throughput, high-quality manufacturing. This technology not only improves device performance but also accelerates the commercial adoption of 2D materials across numerous industries.

Whether you’re a researcher or an industry professional, understanding and embracing robotic automation in 2D materials manufacturing can place you at the forefront of this transformative wave in electronics.

Understanding 2D Materials and Their Potential

Before diving into robotic automation, let’s understand what 2D materials are. These are materials just a few atoms thick — imagine sheets so thin you can’t even see them with the naked eye. Graphene, the most famous 2D material, is a single layer of carbon atoms arranged in a honeycomb lattice. It is incredibly strong, flexible, and an excellent conductor of electricity.

These properties make 2D materials perfect candidates for next-generation electronics like ultra-fast transistors, flexible displays, and highly sensitive sensors. However, working with such delicate layers requires precision to avoid damage during manufacturing.

Why Scalability Is Challenging

Scaling up 2D materials manufacturing faces several hurdles:

- Delicate Handling: These materials can easily tear, wrinkle, or contaminate.

- Layer Assembly: Many devices require stacking different 2D materials with precise alignment.

- Clean Interfaces: Dirt or polymer residues trapped between layers reduce performance.

- Repeatability: Manual processes are slow, inconsistent, and not viable for mass production.

This is where robotic automation steps in, enabling controlled, repeatable, and high-throughput manufacturing.

How Robotic Automation Transforms 2D Materials Production

1. Precision Handling and Transfer

Robotic systems use highly controlled gripping and adhesion mechanisms to gently pick up and place 2D material sheets onto substrates. This prevents mechanical strain that could cause tears or wrinkles.

Example: A robotic platform has been developed that processes up to 180 wafers per day while maintaining the electrical quality of graphene sheets. The graphene produced had carrier mobilities over 14,000 cm²/V·s, close to the theoretical ideal — a key indicator of high conductivity.

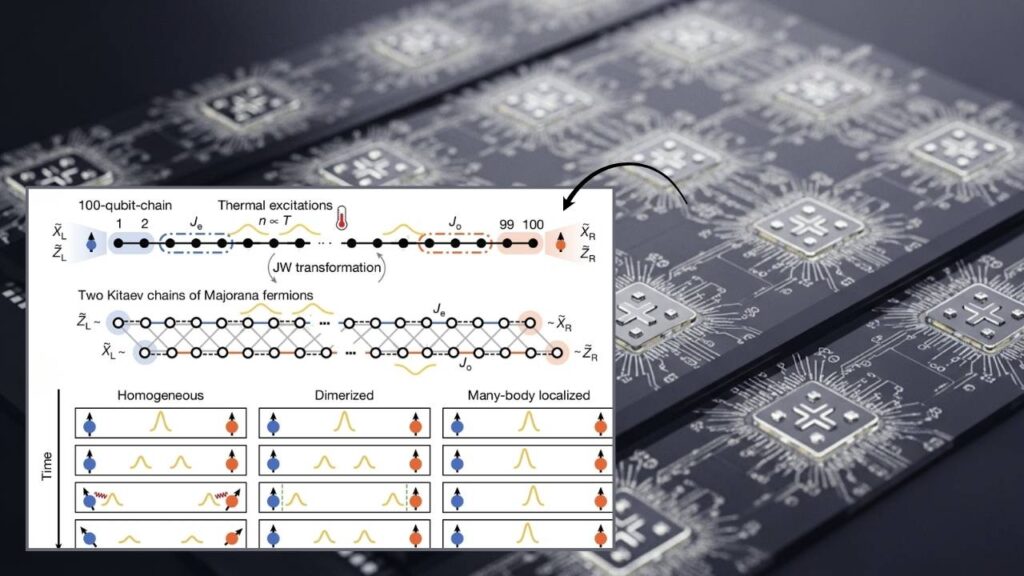

2. Automated Assembly of Van der Waals Heterostructures

Many electronic devices require stacking different 2D materials, such as graphene layered with molybdenum disulfide, to create novel electronic properties. Robots can automatically identify flakes, align layers with nanoscale precision, and assemble these heterostructures, reducing human error and increasing throughput.

This automated stacking supports research into superconductivity and novel quantum effects while paving the way for scalable manufacturing.

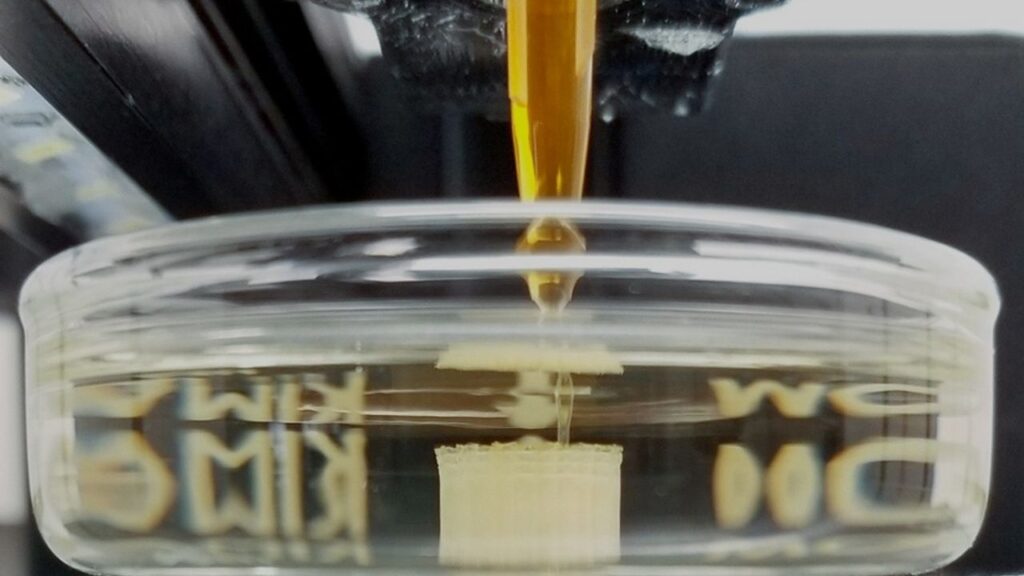

3. Achieving Clean Interfaces for High-Performance Devices

Ensuring interfaces between layers are atomically clean is essential. Residues from transfer polymers degrade device performance.

Robotic systems use a combination of heat and controlled mechanical pressure to remove polymer residues between stacked layers, resulting in clean, high-quality interfaces. This breakthrough leads to better electrical performance and device reliability.

4. High-Throughput Fabrication for Industry

Automation enables scaling production from experimental lab-scale to industrial volumes. With robotics, manufacturers can achieve consistent quality at speeds necessary for commercial viability, such as mass-producing flexible electronics and photonic devices.

5. Integration of Artificial Intelligence and Machine Learning

The future of robotic automation in 2D materials involves integrating AI and machine learning. These technologies optimize process parameters in real-time, predict failures before they happen, and speed up discovery of new materials by analyzing large datasets.

AI-powered robotic systems can adjust conditions on the fly, ensuring even higher quality and yield, while reducing material waste and production costs.

Practical Steps to Implement Robotic Automation in 2D Materials Manufacturing

If you’re working in research or industry, here’s a straightforward guide on how to leverage robotic automation for 2D materials:

Step 1: Define Your Material and Device Requirements

- Identify the 2D materials needed (e.g., graphene, MoS₂).

- Determine device architecture and required heterostructures.

Step 2: Choose Robotic Systems with Fine Control

- Select robots equipped with precise force sensors and high-resolution vision systems.

- Ensure the system can control temperature and pressure during transfers.

Step 3: Develop Protocols for Automated Transfer and Assembly

- Program the robot to pick, align, and place flakes with nanoscale accuracy.

- Automate cleaning processes using heat and pressure to remove residues.

Step 4: Test Electrical and Structural Performance

- Validate the electrical properties such as carrier mobility.

- Use microscopy to verify clean interfaces and layer alignment.

Step 5: Scale Production with Continuous Monitoring

- Employ inline sensors to monitor quality.

- Optimize process parameters using AI to increase yield.

Why This Matters for Professionals and Industries

Robotic automation brings several advantages:

- Reliability: Reduces human error, ensuring device consistency.

- Efficiency: Increases throughput, reducing costs.

- Quality: Maintains the intrinsic properties of delicate 2D materials.

- Innovation: Enables complex device architectures previously impossible at scale.

- Sustainability: Minimizes waste by reducing failed transfers and defective layers.

Industries including semiconductors, flexible electronics, photonics, and sensors stand to benefit immensely. The shift from manual to robotic manufacturing will accelerate commercialization and bring innovative 2D material-based products to market.

Rice University Researchers Discover New 2D Material With Exceptional Adhesion Properties

ISRO Declares 2025 as Gaganyaan Year with December Launch Featuring Humanoid Robot Vyommitra

Berkeley Lab Unveils Doudna Supercomputer to Propel AI and Genomics Research

FAQs About Robotic Automation Enhances Scalability of 2D Materials for Electronic Devices

What Are 2D Materials Used For?

2D materials are used in electronics (like transistors and flexible displays), sensors, photonics, energy storage, and quantum computing.

How Does Robotic Automation Improve 2D Material Manufacturing?

It provides precise control over fragile material handling, automated stacking, cleaning interfaces, and scaling production speed while maintaining quality.

What Challenges Remain?

Scaling costs, integrating with existing manufacturing lines, and developing standards for robotic processes are ongoing challenges.

How Can Small Research Labs Benefit?

Even small labs can adopt scaled-down robotic systems to improve reproducibility and accelerate experimentation, gaining a competitive edge.

What Is the Future Outlook?

The future points toward smart manufacturing powered by robotics and AI, making 2D materials widely accessible for commercial products.