In a world facing growing environmental challenges from plastic pollution, scientists have made a remarkable breakthrough: a new supermaterial made from bacterial cellulose that could replace traditional plastics, metals, and glass. This material is not only strong—comparable to metals and glass—but also flexible, transparent, and biodegradable. This exciting innovation promises to combine the best qualities of multiple materials while being friendly to our planet.

Table of Contents

Scientists Create Supermaterial That Outperforms Metal and Glass

| Aspect | Details |

|---|---|

| Material | Bacterial cellulose nanofibril sheets |

| Tensile Strength | Up to 436 MPa; increased to 553 MPa with boron nitride integration |

| Key Properties | Flexible, foldable, transparent, biodegradable, excellent heat dissipation |

| Environmental Benefit | Fully biodegradable, no microplastic pollution, absence of harmful chemicals |

| Applications | Packaging, electronics, energy storage, construction, textiles |

| Production Method | Rotational bioreactor aligning bacterial cellulose fibers in real-time |

| Official Project Website/Educational Resource | Nature Communications – Supermaterial from bacterial cellulose |

The creation of bacterial cellulose-based supermaterials represents a transformative step toward sustainable, high-performance alternatives to plastics, metals, and glass. By aligning natural cellulose fibers produced by bacteria, scientists have engineered a biodegradable, transparent, strong, and flexible material that holds promise across multiple industries, from packaging to electronics to construction.

This fusion of biology and engineering could herald a future where we say a true “goodbye” to traditional plastics and their environmental pitfalls, embracing eco-friendly materials that meet the demands of modern technology and industry.

What Is Bacterial Cellulose and Why Is It Special?

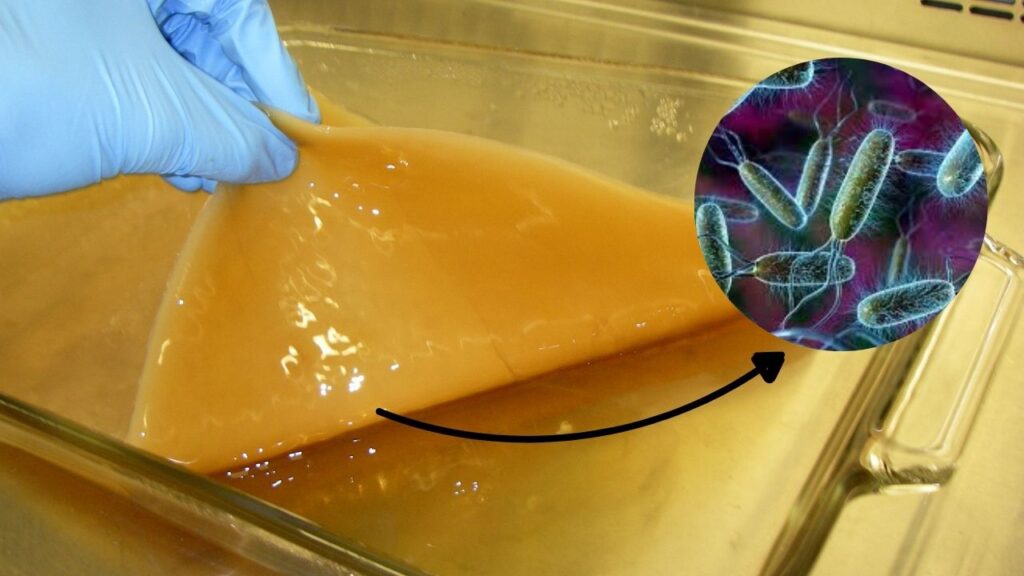

Bacterial cellulose (BC) is a natural substance produced by certain bacteria that form ultra-thin fibers much finer than plant cellulose. Unlike plant-based cellulose, which contains impurities like lignin, bacterial cellulose is ultra-pure and has a highly organized nanofiber network. This makes it mechanically strong, lightweight, and very adaptable.

Because BC is grown by bacteria using renewable resources and mild conditions, it is fully biodegradable and does not produce harmful microplastics or toxic chemicals such as bisphenol A (BPA) commonly found in synthetic plastics. This makes bacterial cellulose an excellent candidate for replacing traditional plastics in many applications.

How Did Scientists Turn Bacterial Cellulose into a Supermaterial?

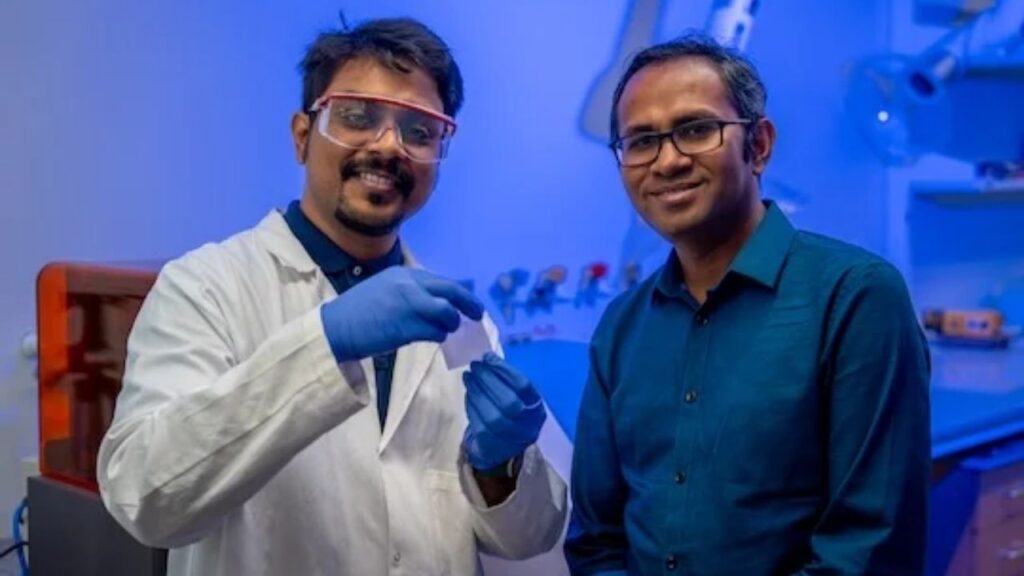

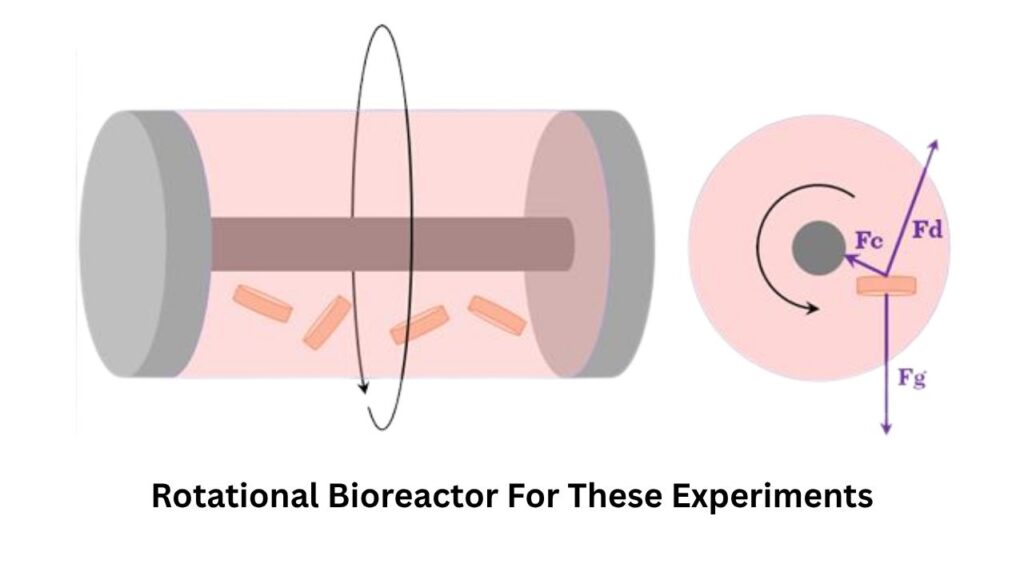

The key challenge with bacterial cellulose has been that the fibers usually grow in random orientations, which limits the material’s strength and performance. Researchers at Rice University and the University of Houston found a solution by inventing a rotational bioreactor that spins a culture of cellulose-producing bacteria. This spinning motion creates a controlled fluid flow that directs the bacteria to move and produce cellulose fibers in an aligned, orderly fashion.

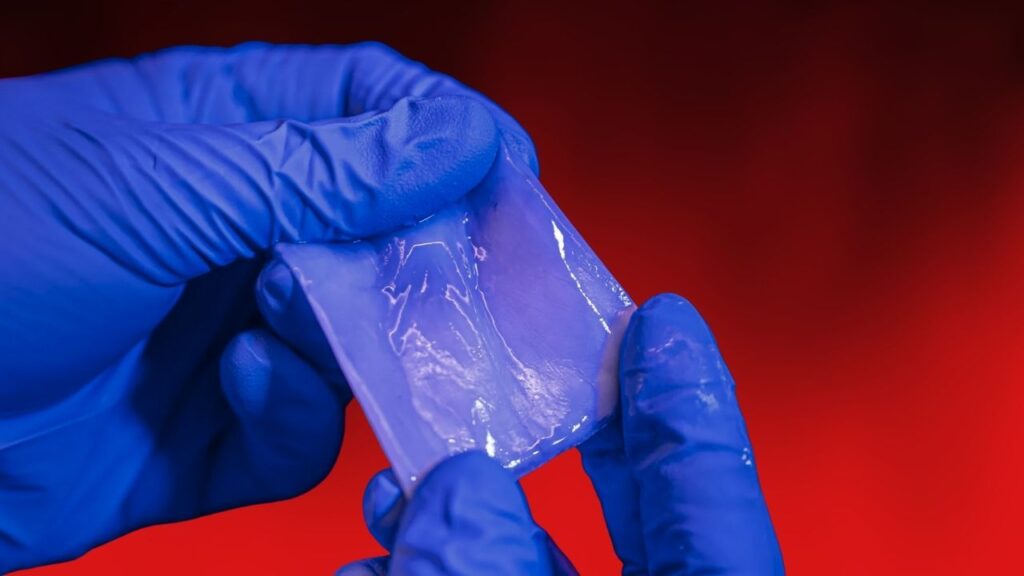

This real-time alignment of nanofibrils leads to bacterial cellulose sheets with extraordinary properties:

- Tensile strength up to 436 megapascals (MPa), similar to some metals and glass

- Strong yet flexible, foldable, and transparent—unlike brittle glass or heavy metals

- Fully biodegradable, leaving no microplastic residue

- Can incorporate nanomaterials like boron nitride nanosheets to increase strength to 553 MPa and enhance heat dissipation

- Potential for customizable mechanical and functional properties by adding different nanoscale additives during growth

In a way, the scientists “train” the bacterial community to produce cellulose in a highly disciplined and purposeful manner, turning naturally occurring biopolymer into an environmentally friendly supermaterial.

Why This Innovation Is Revolutionary

Plastic has become ubiquitous due to its lightness, flexibility, and low cost. Yet, its environmental cost is staggering, with synthetic plastics breaking down into microplastics that pollute ecosystems and release toxic chemicals. Metals and glass, although durable, are often heavy, brittle, or energy-intensive to produce.

This bacterial cellulose supermaterial offers a unique combination of desirable properties:

- Strength to rival metals and glass yet with the flexibility of plastic

- Transparency, which opens possibilities for protective coatings, flexible displays, or packaging

- Manufactured from abundant, renewable sources without relying on fossil fuels

- Biodegradability, breaking down safely without toxic residues or microplastics

- Versatility and scalability through a single-step, controllable biosynthesis process

The ability to add nanoscale additives (like boron nitride) during bacteria cultivation further enhances thermal and mechanical properties, tailoring materials to specific industrial needs.

Practical Applications and Industry Impact

Packaging Industry

Imagine packaging that is not only tough and clear but also eco-friendly and compostable. This technology could dramatically reduce plastic waste from consumer goods, food packaging, and shipping materials by replacing fossil-fuel-based plastics with biodegradable alternatives.

Electronics and Displays

Strong, transparent, and flexible bacterial cellulose sheets could be used to develop next-generation screen protectors, flexible displays, wearable electronics, and lightweight protective casings. Enhanced heat dissipation capabilities are particularly valuable for electronic components.

Construction and Textiles

With metal- or glass-like strength but far less weight, these materials could contribute to sustainable construction by reinforcing structures while reducing carbon footprint. In textiles, bacterial cellulose fibers could yield durable, breathable, and biodegradable fabrics for clothing and technical uses.

Energy Storage and Thermal Management

Incorporating boron nitride nanosheets gives the material superior heat dissipation — three times faster than controls — making it excellent for battery casings, thermal interface materials, and other energy storage devices needing efficient heat removal.

How Is This Material Manufactured?

- Bacterial Cultivation: Special cellulose-producing bacteria are grown in nutrient media.

- Rotational Bioreactor: The culture is placed inside a cylindrical reactor that spins, generating directional fluid flow.

- Nanofibril Alignment: The controlled motion encourages bacteria to move in a coordinated path, producing aligned cellulose fibers.

- Sheet Formation: The aligned nanofibrils aggregate into thin, strong, transparent sheets.

- Nanomaterial Integration: For enhanced properties, additives such as boron nitride can be introduced during growth.

- Harvest and Processing: The sheets are harvested and processed into desired shapes for industrial uses.

This bottom-up biosynthesis is highly adaptable and scalable, allowing precise control over fiber orientation and material characteristics.

New Quantum State Discovery Set to Revolutionize Material Science Worldwide

FAQs About Scientists Create Supermaterial That Outperforms Metal and Glass

Q1: How is bacterial cellulose different from regular plant cellulose?

Bacterial cellulose is purer and about 100 times finer than plant-derived cellulose. It forms a nanofibrillar network free of lignin and other impurities, making it stronger and more suitable for high-performance applications.

Q2: Is this supermaterial safe and environmentally friendly?

Yes. It is fully biodegradable and does not release harmful microplastics or chemicals, offering a sustainable alternative to conventional plastics.

Q3: Can this material be produced on a large scale?

The rotational bioreactor method is designed for scalability and can be adapted for commercial production in various industries.

Q4: Which industries stand to benefit the most?

Packaging, electronics, construction, textiles, and energy storage sectors can all leverage this supermaterial to improve sustainability and performance.

Q5: How well does the material handle heat?

When combined with boron nitride nanosheets, heat dissipation improves threefold, making it excellent for thermal management in electronics and batteries.