3D printing is no longer just about creating shapes from plastic or metal layers. Thanks to multi-material 3D printing, scientists and engineers can now encode multiple properties—such as strength, flexibility, conductivity, and color—directly into a single printed object. This breakthrough allows the creation of complex, multifunctional devices all in one seamless print, revolutionizing manufacturing, robotics, medicine, and many other industries.

In this detailed guide, we will explore what multi-material 3D printing is, how it works, real-world examples, challenges, and practical steps to get started. Whether you’re a student, hobbyist, or professional engineer, this article breaks down the technology in simple terms with useful insights.

Table of Contents

Scientists Encode Multiple Properties Into a Single Material Using 3D Printing Magic

| Feature | Details |

|---|---|

| Core Technology | Combines two or more materials with distinct properties within a single 3D print. |

| Common Techniques | Dual-extrusion FDM, material jetting (PolyJet), multi-material laser sintering, hybrid methods. |

| Applications | Robotics, medical implants, electronics, automotive, bioengineering. |

| Advantages | Customizable localized properties, less assembly, complex integrated designs. |

| Limitations | Interface resolution, material compatibility, slower print speeds. |

| Official Resource | Wikipedia: Multi-material 3D Printing |

Multi-material 3D printing is transforming the way we create objects by encoding different properties into a single part. This allows engineers and designers to imagine and build smarter, smaller, and more functional devices across many industries including robotics, healthcare, and automotive. While challenges remain, ongoing advancements continue to improve printing quality, speed, and material compatibility.

Whether you’re a seasoned professional or an enthusiastic maker, embracing multi-material 3D printing can open exciting opportunities to innovate and iterate faster. Experimenting with these technologies lets you experience firsthand the magic of encoding multiple functions and properties inside one printed piece.

What is Multi-Material 3D Printing?

Unlike traditional 3D printing where only one material is used throughout the object, multi-material 3D printing mixes two or more materials within the same part. This makes it possible to combine properties like rigidity and flexibility, or insulation and conductivity, in one cohesive design.

For example, instead of printing a robotic arm with separate rigid parts and soft joints assembled later, engineers can print the entire arm as one piece with different material zones suited to each function. This capability unlocks incredible design freedom and performance improvements.

Why does it matter?

- Functional Integration: Devices can have rigid supports, flexible hinges, conductive pathways, and aesthetic finishes—all in one print.

- Compact & Lightweight Designs: Combining materials reduces the need for bulky assembly.

- Simplified Manufacturing: Eliminates multi-step assembly, reducing cost and production time.

- Innovation: Enables designs that were previously too complex or impossible.

How Does Multi-Material 3D Printing Work?

Here are the main methods used to print with multiple materials:

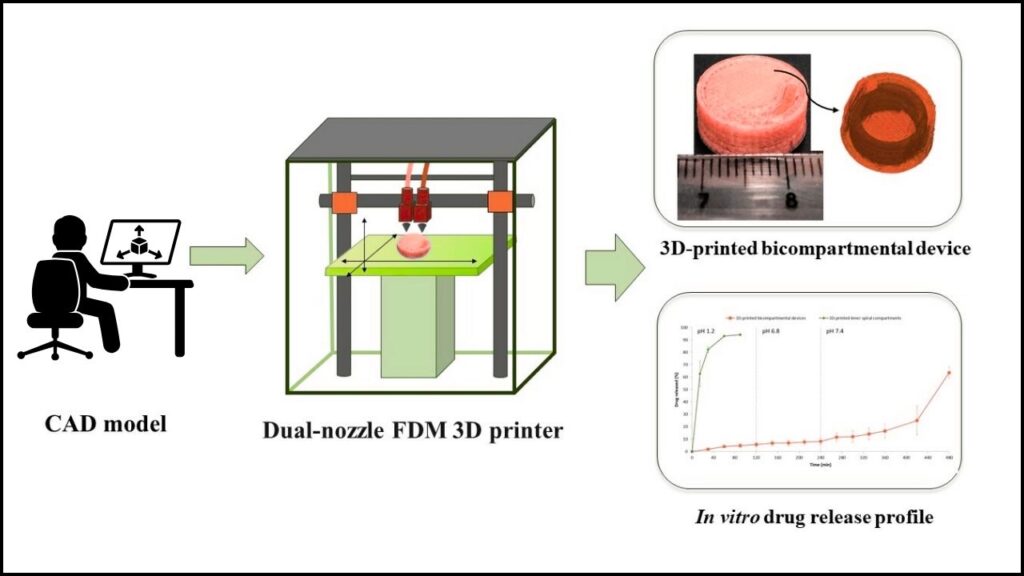

1. Dual-Extrusion Fused Deposition Modeling (FDM)

- Uses two or more nozzles, each extruding a different thermoplastic filament.

- Can combine flexible materials like TPU with rigid plastics like ABS in one object.

- Example: a phone case with a hard outer shell and soft inner cushioning printed simultaneously.

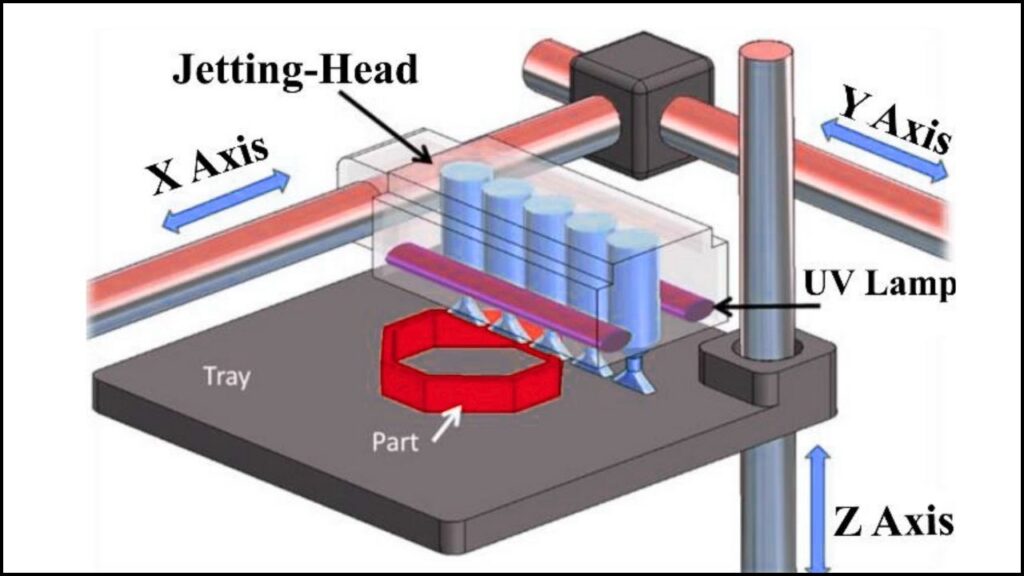

2. Material Jetting (PolyJet)

- Prints multiple photopolymer resins drop-by-drop.

- Each resin can have different properties—rigid, flexible, transparent, colored.

- Layers are cured instantly with UV light.

- Precision is very high, making it ideal for medical models and prototypes requiring different tissue-like materials.

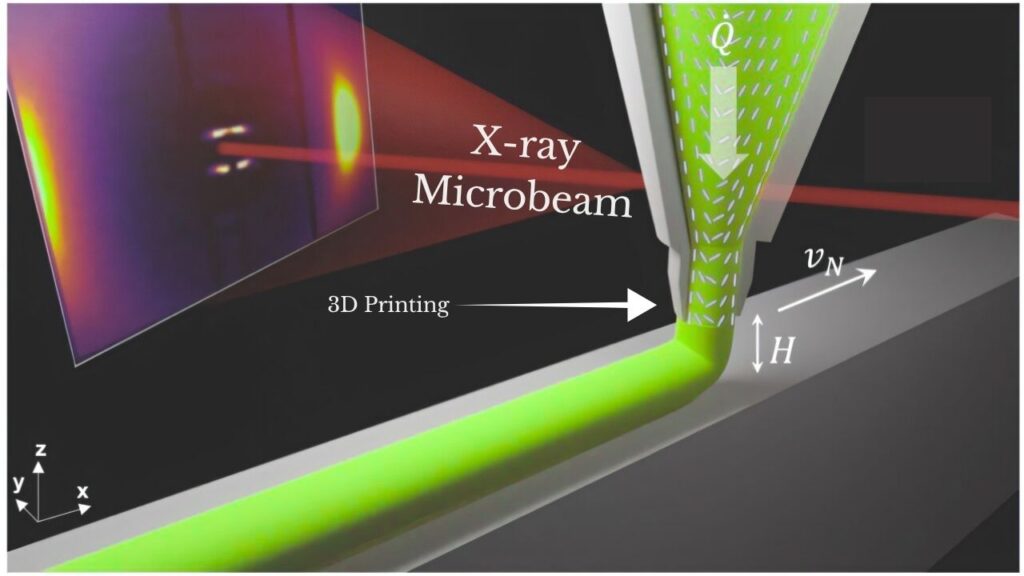

3. Multi-Material Laser Sintering (MMLS)

- Selectively melts different powder materials (metal, ceramic, polymer) layer by layer.

- Produces high-strength parts with zones of varied properties.

- Often used for aerospace and automotive components.

4. Hybrid Additive-Subtractive Manufacturing

- Combines 3D printing with CNC machining.

- Allows precise finishing and tight tolerances on multi-material parts.

- Used for production parts needing both complex geometry and exact dimensions.

Real-Life Applications and Benefits

Robotics

Multi-material 3D printing allows robots to have parts that are simultaneously strong and flexible. For instance, robotic grippers can feature rigid claws for gripping objects, connected by flexible, soft joints—printed all in one go without assembly.

Medical Implants

Custom implants can incorporate rigid supports for strength with soft cushioning where tissues interact. This leads to more comfortable, longer-lasting implants tailored to each patient.

Electronics

Multi-material printing can embed conductive traces or sensors within structural parts, enabling compact, integrated smart devices.

Automotive and Aerospace

Lightweight components that combine metals and polymers can reduce vehicle weight while maintaining strength and durability, improving fuel efficiency and performance.

Practical Guide: How to Get Started With Multi-Material 3D Printing

Step 1: Identify Required Properties

Decide what features your final object needs — be it strength, flexibility, electrical conductivity, color, or resistance to heat or chemicals. Choose materials accordingly.

Step 2: Choose the Right Printer

- For plastics: Dual-extrusion FDM or PolyJet printers.

- For metals or composites: Multi-material laser sintering printers.

- Check if your printer supports the materials and has multi-nozzle or multi-jet capabilities.

Step 3: Design Your Model Properly

Use CAD software that supports assigning different materials to different sections of your model. Pay attention to transitions between materials to avoid weak spots.

Step 4: Configure Slicing Software

Prepare your print job with slicing software that can handle multiple materials — coordinating extrusion, temperature, and curing as needed.

Step 5: Prototype and Test

Print test parts to validate bonding between materials, mechanical properties, and functional performance. Iterate to refine settings.

Common Challenges and How to Overcome Them

| Challenge | Solution |

|---|---|

| Materials Compatibility | Research material chemistry, use proven pairings, or intermediate bonding agents. |

| Material Interface Quality | Use printers with high-resolution calibration and optimized slicer settings. |

| Waste Material | Employ printers capable of filament mixing to minimize purge waste. |

| Longer Print Times | Balance complex designs with production schedules; optimize print settings. |

Cold Spray 3D‑Printing Technique Proves Effective For On‑Site Bridge Repair

This New 3D Chain Mail Bends, Adapts, and Protects — The Future of Wearable Armor Is Here

Scientists Use DNA as a Building Block to Create Customized 3D Materials with Unique Properties

FAQs About Scientists Encode Multiple Properties Into a Single Material Using 3D Printing Magic

Can I use multi-material 3D printing on any printer?

No. Only specialized printers with dual or multiple extrusion systems, or material jetting heads, support multi-material printing.

Which materials can I combine?

Commonly used are thermoplastics (like PLA, ABS, TPU), photopolymers, metals, ceramics, and composites, depending on the printing technology.

Is multi-material 3D printing expensive?

It can be more costly due to advanced hardware and materials, but savings in assembly, prototyping, and product functionality often justify the investment.

How strong are multi-material prints?

Strength depends on material choices and interface bonding quality. Modern techniques produce robust parts, though interfaces may remain the weaker zone to watch.

Can I print electrical components?

Yes. Conductive materials can be included to print embedded circuitry or sensors within structural parts.