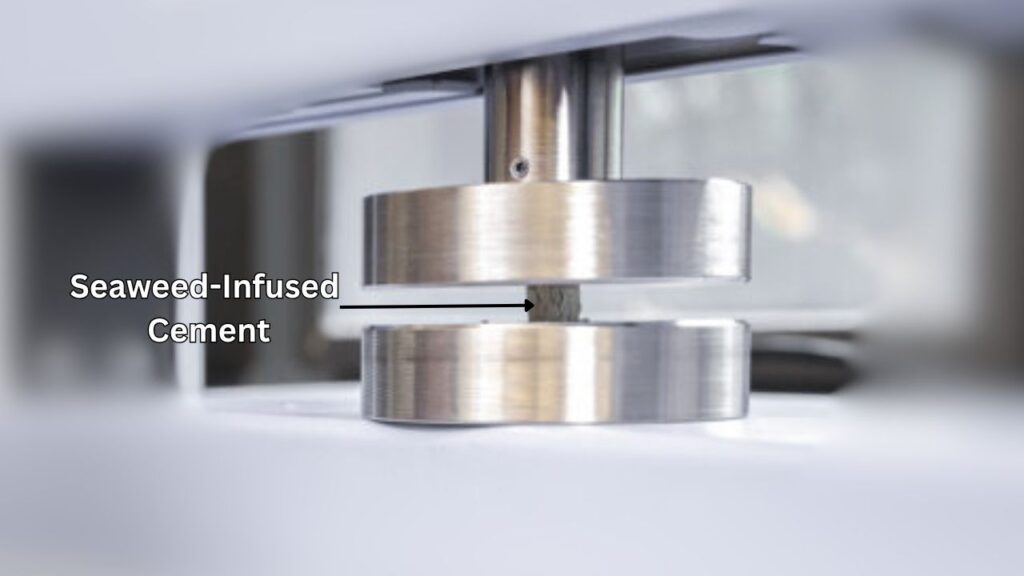

Seaweed-infused cement is emerging as a promising solution to one of the world’s biggest environmental challenges: the enormous carbon footprint of concrete. Researchers at the University of Washington and Microsoft have developed a new type of cement that blends powdered seaweed with traditional cement, cutting carbon emissions by up to 21%—all while maintaining the strength and durability that builders depend on.

Concrete is the second-most-used material on Earth, after water. Every building, bridge, and road depends on it. But there’s a significant downside: making the cement that binds concrete together is highly carbon-intensive. In fact, cement production is responsible for nearly 10% of global CO₂ emissions. For every kilogram of cement produced, almost a kilogram of CO₂ is released into the atmosphere, mainly from burning fossil fuels and a chemical process called calcination.

With cities expanding and climate change accelerating, finding ways to make concrete greener is not just a good idea—it’s a global necessity. Enter seaweed. Unlike other additives, seaweed is a natural carbon sink, absorbing CO₂ as it grows. By mixing dried seaweed powder into cement, researchers have created a product that’s not only less harmful, but actively better for the planet.

Table of Contents

Seaweed-Infused Cement

| Feature | Traditional Cement | Seaweed-Infused Cement |

|---|---|---|

| Carbon Emissions | ~1 kg CO₂ per 1 kg cement | 21% lower |

| Strength | Industry standard | Retained or improved |

| Material Innovation | Limestone, clay, fossil fuels | Green seaweed powder |

| Production Speed | Months/years for new formulas | 28 days using AI |

| Environmental Benefit | High emissions | Carbon-sequestering |

| Scalability | Global, mature industry | Lab/pilot scale |

| Cost | Well established | Minimal processing needed |

| Official Source | University of Washington News |

Seaweed-infused cement is a real breakthrough in the push for greener, stronger concrete. By combining the natural carbon-absorbing power of seaweed with advanced material science and artificial intelligence, researchers have developed a product that could make a big dent in the construction industry’s climate impact—without asking builders to give up strength or durability.

With global demand for concrete only increasing, scalable, affordable ways to cut emissions are more important than ever. Seaweed-based materials, accelerated by smart technology like machine learning, offer a path forward that’s both innovative and practical. As these technologies move from the lab to the construction site, they could help build the sustainable cities of the future.

Source: University of Washington News

The Big Picture: Why Cement’s Carbon Footprint Matters

Cement is the glue that holds concrete together. Without it, we wouldn’t have the homes, schools, hospitals, and roads that make up modern life. But making cement is very energy-intensive. Huge kilns, often burning coal or gas, heat limestone and clay to over 1,400°C (2,500°F). This process, called calcination, turns limestone into lime and releases CO₂ as a byproduct.

Globally, cement production pumps out about 8–11% of all CO₂ emissions—that’s more than the entire aviation industry. With demand for concrete expected to keep rising, especially in fast-growing countries, tackling cement’s climate impact is urgent.

How Does Seaweed-Infused Cement Work?

The process is refreshingly straightforward: replace some of the traditional cement with dried, powdered seaweed. Seaweed grows quickly, doesn’t need fresh water or fertilizers, and absorbs CO₂ as it grows. When added to cement, seaweed powder directly reduces the amount of standard cement needed, and because the seaweed has already captured carbon, it doesn’t add to the overall emissions.

The team at the University of Washington focused on a green seaweed called Ulva, chosen for its sturdy cellular structure, which may help reinforce the cement, not just replace it.

Other types of seaweed or algae could also work, but Ulva seems to offer a good balance of strength and carbon-sequestering ability.

The Power of Machine Learning

Finding the right mix wasn’t simple. Concrete takes about a month to cure, so trying every possible formula by hand would take years. To speed things up, the researchers used machine learning—a kind of artificial intelligence—to predict which mixtures would work best. In just 28 days, they found a combination that not only passed industry strength tests but also had a 21% lower global warming potential.

As one of the researchers explains, “Machine learning was integral in helping us dramatically shorten the process—especially important here, because we’re introducing a completely new material into cement.”

Step-by-Step Guide: Making Seaweed-Infused Cement

Here’s a simple breakdown of how this innovative cement is made and tested:

- Harvest the seaweed: Green seaweeds like Ulva are grown in marine farms or collected from clean, coastal waters.

- Dry and powder the seaweed: The seaweed is dried (using the sun or an oven) and then ground into a fine powder.

- Mix with cement: The seaweed powder is blended into the cement mix, replacing a portion of the traditional cement.

- Test and optimize: Machine learning helps quickly test different mixtures to find the best balance of strength and low emissions.

- Produce concrete: The final seaweed-cement blend is used just like regular cement to make concrete for construction.

Why Is This Innovation Important?

- Reduces Carbon Emissions: 21% less CO₂ is a big deal. If scaled up, this could save millions of tons of carbon dioxide each year.

- Retains Strength: The new cement is just as strong as the old, so builders don’t have to compromise quality for sustainability.

- Local and Scalable: Seaweed can be grown almost anywhere with seawater, making this a globally relevant solution.

- Simple Processing: Unlike some other green alternatives, seaweed doesn’t need complicated or expensive processing before being added to cement.

- AI-Powered Discovery: The use of machine learning shows how technology and nature can team up to solve big problems, and fast.

Beyond Cement: Other Uses of Seaweed in Construction

Seaweed isn’t just being used to replace cement. Researchers are also testing its use as a sand substitute in lightweight concrete. In some studies, up to 30% of natural sand was replaced with seaweed waste, resulting in lighter, greener concrete that still meets strength standards. While this is different from cement replacement, it highlights seaweed’s versatility as a sustainable construction material.

What Builders, Architects, and Engineers Should Know

If you work in construction, here’s what you can do:

- Stay updated: Keep an eye on new developments in seaweed-infused cement and other low-carbon building materials.

- Ask your suppliers: As these products become available, ask your cement suppliers about low-carbon options—including those using seaweed.

- Pilot projects: Consider testing seaweed-based materials in smaller, less critical projects to see how they perform in your environment.

- Support sustainability: Advocate for policies and incentives that encourage the use of eco-friendly building materials.

- Collaborate: Work with researchers and material scientists to test new mixes and provide practical feedback from the field.

Breakthrough Carbon Capture Method Could Make Cement Ingredients Climate-Friendly

Breakthrough Catalyst Efficiently Converts CO₂ Into Methanol With High Precision

FAQs About Seaweed-Infused Cement

Q: Is seaweed-infused cement as strong as regular cement?

A: Yes, early tests show that the strength of seaweed-infused cement matches or even exceeds that of traditional cement.

Q: How much carbon does seaweed cement actually save?

A: 21% less CO₂ is the figure from the University of Washington’s research.

Q: Where can I buy seaweed-infused cement?

A: Right now, this is mostly at the laboratory and pilot scale. Wider commercial availability will depend on further testing and industry adoption.

Q: Will seaweed make concrete more expensive?

A: Seaweed is abundant, renewable, and easy to process, so costs should remain competitive, but large-scale economics are still being studied.

Q: Can seaweed be used in other concrete ingredients?

A: Yes! Researchers are also testing seaweed as a sand substitute in lightweight concrete, which could also help reduce environmental impacts.

Q: Is this just for new builds, or can it be used for repairs?

A: In theory, seaweed-infused cement could be used anywhere traditional cement is used, including repairs, but real-world durability testing is still underway.