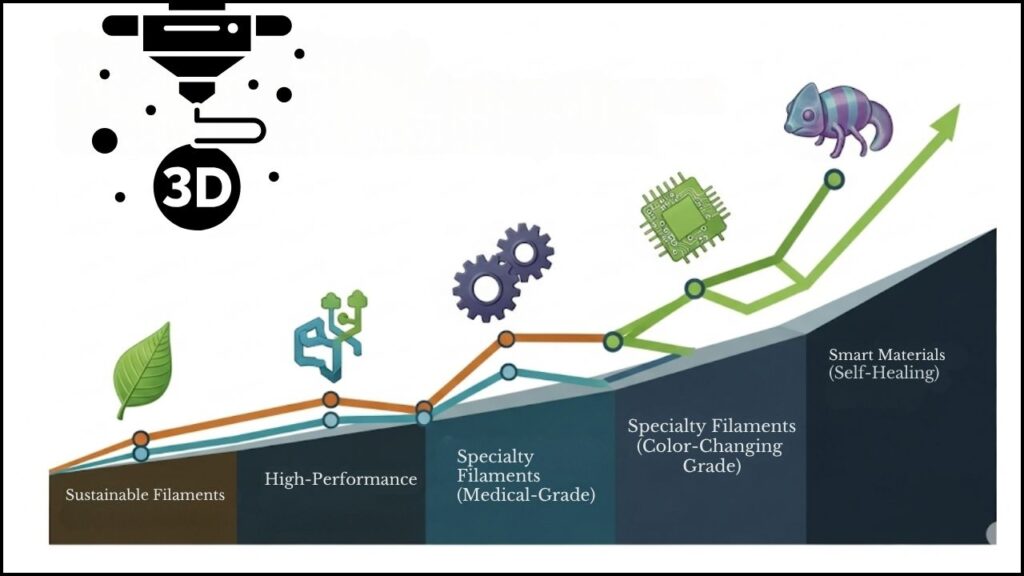

3D printing filaments are experiencing an extraordinary transformation in 2025, revolutionizing how industries design and manufacture products. This year marks a major shift where bio-innovation, smart materials, AI-driven automation, and sustainability come together to push the boundaries of what additive manufacturing can achieve.

The 3D printing filament market, valued at approximately $1.27 billion in 2025, is on track to nearly triple, reaching about $3.83 billion by 2034, with an expected annual growth rate of 13%. This growth is fueled by the rising demand for lightweight, durable, and customized components across sectors such as automotive, aerospace, healthcare, and consumer goods. What are the key trends driving this rapid evolution, and how can professionals and enthusiasts alike harness these innovations?

Table of Contents

Shocking New Trends Are Redefining 3D Printing Filaments in 2025

| Aspect | Details |

|---|---|

| Market Size | $1.27 billion in 2025; projected $3.83 billion by 2034 |

| Annual Growth Rate (CAGR) | 13.08% from 2025 to 2034 |

| Dominant Region | North America |

| Fastest Growing Region | Asia Pacific |

| Advanced Filament Types | Bio-based, smart/electrical, flexible/self-healing, optical-grade, spool-less/refillable |

| Key Industry Applications | Aerospace, medical, automotive, consumer goods, soft robotics |

| AI Integration | AI optimizes filament design, extrusion quality, waste reduction, and predictive printing |

| Sustainability Focus | Biodegradable filaments, recycled materials, zero-waste spool-less systems |

| Major Challenges | Regulatory validation, supply chain logistics, greenwashing concerns |

| Official Market Source | Precedence Research on 3D Printing Filament Market |

The 3D printing filament landscape in 2025 is undergoing a profound transformation, driven by sustainability, smart material innovation, AI integration, and new manufacturing approaches. This evolution shifts the conversation from “What can we print?” to “What can’t we print?”

For both professionals and hobbyists, embracing these cutting-edge filaments and technologies unlocks unprecedented opportunities to innovate, reduce environmental impact, and meet complex industrial demands.

Understanding 3D Printing Filaments: The Core of Additive Manufacturing

3D printing filament is a thermoplastic or composite material shaped into thin strands, which are fed through a heated nozzle to create 3D objects one layer at a time. The wide variety of filament types, from conventional PLA and ABS to advanced composites involving carbon fiber or biomaterials, allows for a range of physical, chemical, and mechanical properties. These unique features enable manufacturers to tailor parts for strength, flexibility, transparency, conductivity, or biodegradability depending on the application.

What’s Shocking and New in 2025?

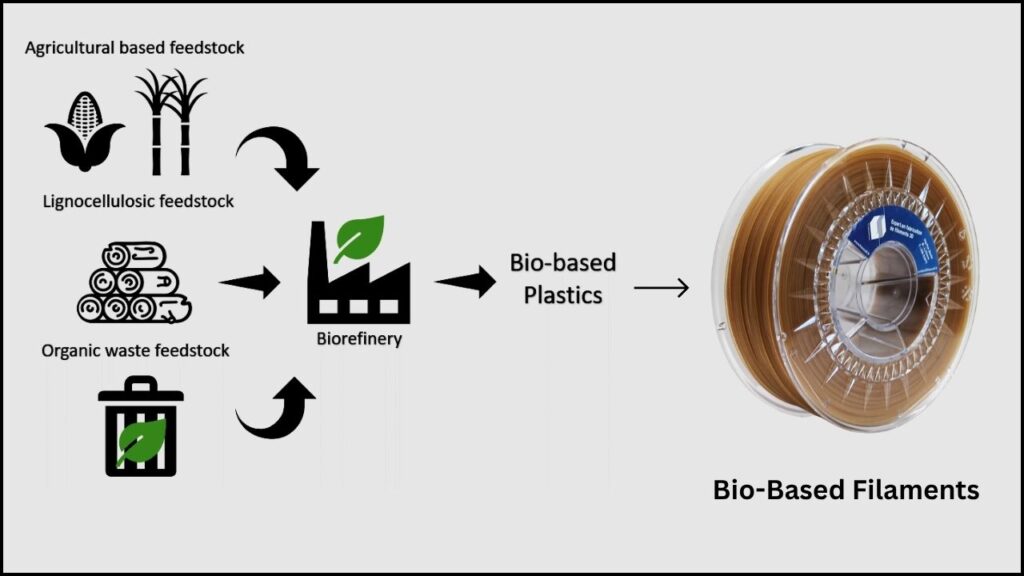

1. Bio-Based and Eco-Friendly Filaments Become Mainstream

Sustainability is no longer an afterthought but a core value driving filament innovation. Bio-based filaments, such as polyhydroxyalkanoates (PHA) produced by microbial fermentation, and modified lignin blends derived from agricultural waste, deliver true biodegradability—far beyond greenwashed marketing claims. These materials often rival or exceed the performance of traditional plastics.

Recycled filaments like reprocessed PETG are also gaining traction, helping industries implement circular manufacturing models that reduce plastic waste and environmental impact. This shift aligns 3D printing with global efforts toward climate responsibility and reduced carbon footprints.

2. Functional and Smart Filaments: Printing the Future

A cutting-edge trend is the rise of smart filaments capable of conducting electricity, self-healing after damage, or sensing environmental changes. These advanced materials make it possible to print soft robotics, wearable electronics, and embedded sensors directly within parts.

Professionals can now manufacture fully integrated electromechanical systems in one print, substantially accelerating prototyping and reducing assembly labor. This capability opens new frontiers in designing lightweight, intelligent devices.

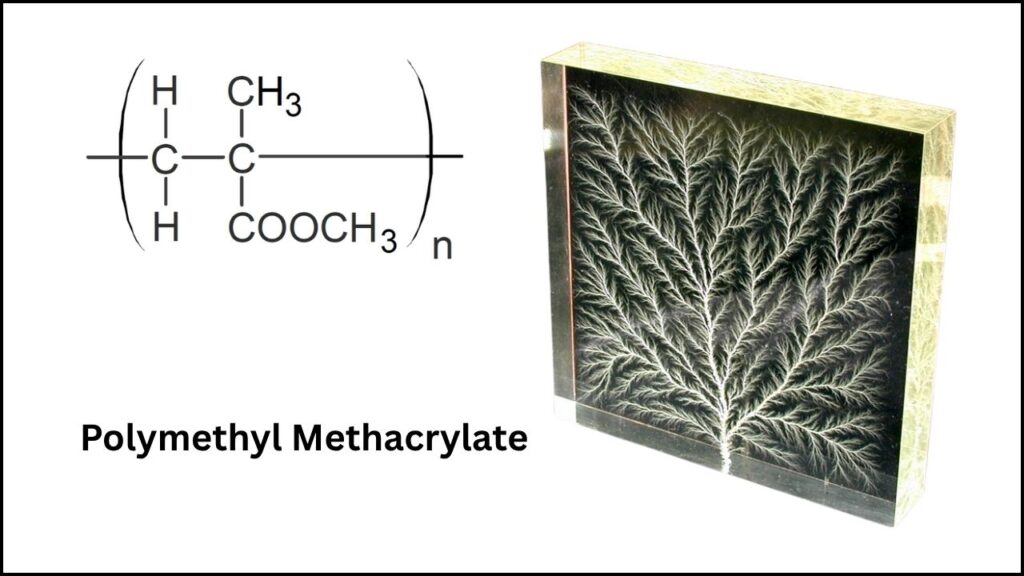

3. Optical-Grade and Light-Diffusing Materials for Precision

2025 introduces transparent filaments crafted from blends such as PMMA (polymethyl methacrylate) and polycarbonate, offering over 90% light transmittance.

These filaments enable precise printing for specialized applications like custom eyewear, augmented reality (AR) devices, and medical optics.

This breakthrough gives engineers control over light behavior within printed components, unlocking new design possibilities in lighting, displays, and medical tools.

4. Flexible and Self-Healing Filaments for Enhanced Durability

Flexibility is essential in fields like prosthetics, medical devices, and soft robotics. New flexible filaments go beyond traditional TPU by incorporating self-healing properties and improved elasticity, enabling parts that can sustain damage and recover their form autonomously.

This biomimetic approach results in more lifelike, durable, and adaptable products that better meet the demands of medical innovation and robotic exploration.

5. AI-Powered Filament Development and Printing Optimization

Artificial intelligence is reshaping filament innovation both in materials science and manufacturing. AI algorithms analyze extensive chemical datasets to design novel filament formulations combining carbon fiber composites, metals, and biomaterials faster than humanly possible.

Furthermore, AI-driven extrusion control minimizes filament breakage and material waste, predicts print quality, and optimizes inventory—boosting efficiency and enabling rapid response to market trends.

6. Zero-Waste Production with Spool-less and Refillable Filaments

A significant industry push is underway to eliminate packaging waste through spool-less filament systems that use recyclable cartridges or refill packs. This innovation supports local and circular manufacturing ecosystems by reducing transport costs, plastic waste, and carbon emissions.

Such developments contribute toward an environmentally conscious and cost-efficient future for additive manufacturing.

7. Material-First Design Automation

Unlike the past where designs adapted to limited filament abilities, emerging CAD and generative design software prioritize filament properties upfront. This approach allows engineers to leverage unique filament strengths—such as flexibility, conductivity, or transparency—to create structurally optimized, innovative parts that were previously impossible.

8. Medical and Bioprinting Breakthroughs Enter Clinical Practice

Biocompatible filaments and bio-inks are moving beyond research labs into everyday clinical uses for tissue scaffolds, personalized implants, and regenerative medicine. This shift enables faster development of patient-specific devices with reduced manufacturing costs and lead times, revolutionizing healthcare delivery.

Practical Advice: Navigating 3D Printing Filaments in 2025

- Select the filament that fits your needs: Determine if your project demands flexibility, transparency, conductivity, or biodegradability, and choose filaments accordingly.

- Utilize AI-enabled tools: Employ software that leverages AI for slice optimization and extrusion control to improve print quality and reduce material waste.

- Commit to sustainability: Whenever possible, opt for bio-based or recycled filaments to support environmentally friendly manufacturing.

- Stay informed: Keep up with filament innovations like self-healing or functional materials to innovate your designs and applications.

- Understand regulations: Particularly in healthcare, ensure your filament materials and printed parts comply with industry standards to avoid costly delays.

Game-Changing 3D Printing Breakthrough Lets Scientists Combine Multiple Materials in One Build

MIT Engineers Develop New 3D Printing Method to Reduce Waste and Enable Complex Designs

Advancements in 3D Printing: How New Materials Are Expanding Possibilities

FAQs About Shocking New Trends Are Redefining 3D Printing Filaments in 2025

Q1: What types of 3D printing filaments are growing fastest?

A: Bio-based filaments, smart functional materials, and spool-less refillable filaments are the fastest-growing due to sustainability and enhanced capabilities.

Q2: How does AI improve filament manufacturing?

A: AI accelerates the creation of new filament formulas, optimizes extrusion to prevent breakage, predicts print quality, reduces waste, and helps manage inventory efficiently.

Q3: Are all bio-based filaments biodegradable?

A: No. Only certain filaments like PHA are truly biodegradable. Beware of misleading claims and verify material specifications.

Q4: Can electronics be printed using 3D filaments?

A: Yes. Conductive filaments enable printing circuits and sensors directly into parts, facilitating integrated electronic devices.

Q5: Which industries benefit most from new filament technologies?

A: Aerospace, automotive, healthcare, consumer goods, and soft robotics are prime beneficiaries of these innovations.