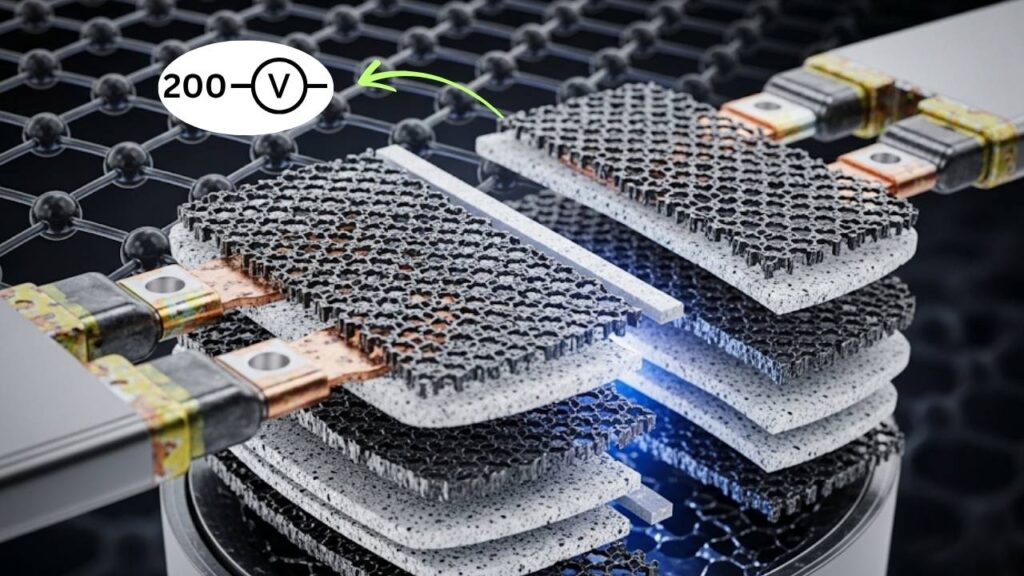

In the ever-evolving field of energy storage, a significant breakthrough has been achieved by researchers at Guangdong University of Technology. They have developed a metal-free graphene supercapacitor stack that is astonishingly paper-thin and capable of generating a high 200 volts in a compact 3.8 cubic centimeters volume. This innovative device eliminates the need for metals entirely, using graphene derived from laser-treated polyimide paper instead.

This article explores the technology behind this cutting-edge supercapacitor, its practical benefits, and what it means for the future of flexible electronics, wearable devices, and other compact systems. Whether you’re a curious learner or a professional working with energy storage solutions, you’ll gain clear insights and detailed explanations accessible to all levels of understanding.

Table of Contents

This Metal-Free Graphene Supercapacitor Generates 200 Volts

| Feature | Details | More Information |

|---|---|---|

| Voltage output | 200 volts | Enough to power 100 LEDs or a 3-watt bulb briefly |

| Device size | Just 3.8 cm³ | Ultra-compact and paper-thin |

| Construction | Metal-free | Graphene paper acts as electrode, connector, and support |

| Fabrication method | Laser-induced graphene (LIG) | Made by CO₂ laser treating polyimide paper |

| Number of stacked cells | 160 tandem thin-film supercapacitors (TFSC) | Stacked cells enable high voltage |

| Electrolyte | Hydrogel electrolyte | Dual functionality as electrolyte and separator |

| Applications | Wearable sensors, flexible electronics, microdevices | Ideal for space-limited or harsh environments |

| Source | Guangdong University of Technology | Official research release |

The pioneering metal-free graphene supercapacitor developed by Guangdong University of Technology offers lightweight, ultra-thin, and flexible high-voltage energy storage by leveraging laser-induced graphene paper and hydrogel electrolytes. Its ability to generate 200 volts in a compact 3.8 cm³ volume without metals is a substantial advancement that could redefine power sources for flexible electronics, wearables, and microdevices.

Though still in the prototype phase, this breakthrough exemplifies the disruptive potential of graphene in next-generation energy storage and opens exciting opportunities for future technologies.

What Is a Supercapacitor and Why Is It Important?

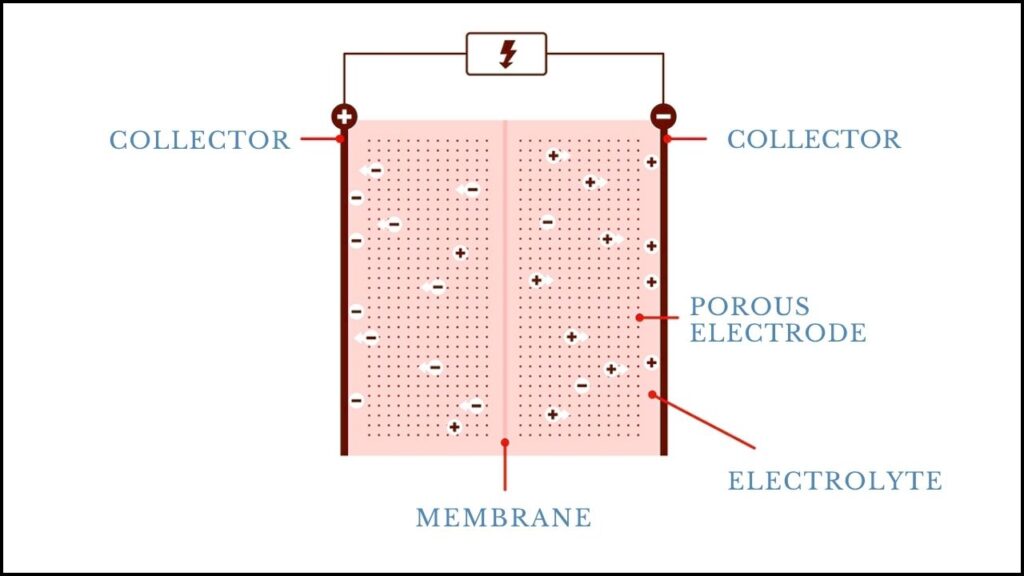

To appreciate this innovation, it’s important to understand supercapacitors in general. A supercapacitor is a type of energy storage device that stores and releases electrical energy faster than batteries. It charges and discharges rapidly and can last for millions of cycles, making it ideal wherever quick bursts of power are needed—such as in regenerative braking in electric vehicles, wearable electronics, and microdevices.

Unlike traditional supercapacitors that rely on metals like aluminum or copper for current collectors and connectors, these metals add weight, bulk, and rigidity, limiting flexibility and design potential.

How Does This Metal-Free Graphene Supercapacitor Work?

This particular supercapacitor does away with metals completely. Instead, it leverages graphene, a one-atom-thick layer of carbon atoms arranged in a hexagonal lattice. Graphene is known for exceptional electrical conductivity, mechanical strength, and flexibility.

The Magic of Laser-Induced Graphene (LIG)

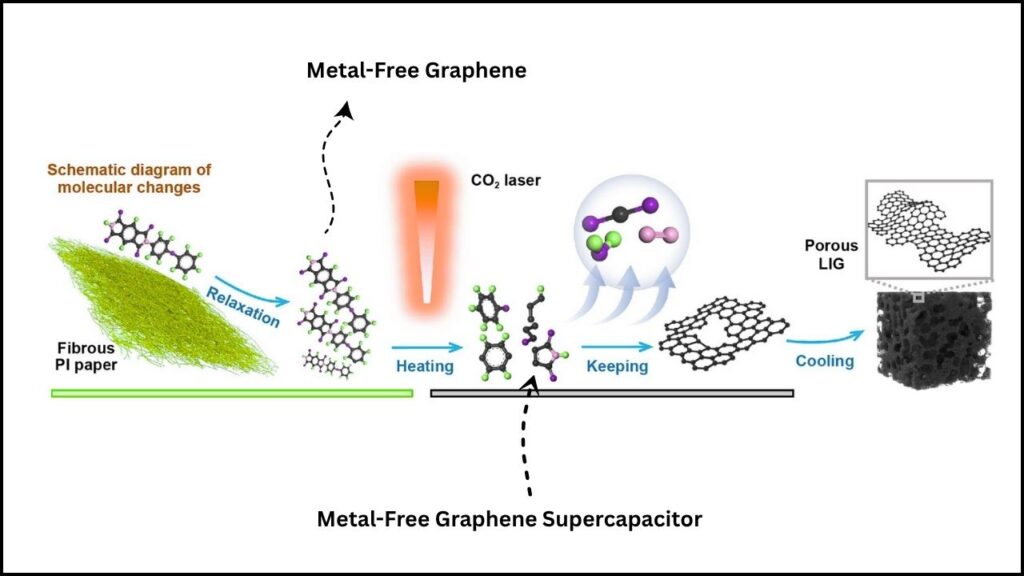

The heart of this design is the conversion of standard polyimide (PI) paper into graphene using a CO₂ laser process:

- Starting Material: A flexible sheet of commercial polyimide paper.

- Laser Treatment: The CO₂ laser selectively heats and transforms the PI paper’s surface into a porous, 3D graphene structure.

- Multi-functional Graphene Paper: This graphene acts as the supercapacitor’s electrode, electrical connector, and structural frame all in one, eliminating the need for metal wiring and supports.

Researchers tuned the laser parameters—such as power, speed, and scan density—to optimize conductivity and mechanical robustness of the graphene sheets.

Stacked Thin-Film Supercapacitors for High Voltage

Each individual supercapacitor cell is thin, just a few millimeters thick. By stacking 160 of these thin-film supercapacitor (TFSC) cells in series, the device achieves a total output of 200 volts within a tiny 3.8 cm³ footprint.

Hydrogel Electrolyte With Double Duty

Between these graphene layers is a special hydrogel electrolyte that serves two important roles:

- Electrolyte: Facilitates ion movement during charging and discharging.

- Separator: Prevents the cells from short-circuiting without requiring an added physical separator.

This helps keep the stack thin, flexible, and simplifies manufacturing.

Real-World Benefits and Applications

Ultra-Compact and Lightweight Design

Because the device removes bulky metals and uses thin laser-induced graphene paper, it is remarkably lightweight and thin. This is a huge advantage for:

- Wearable technology: Comfortable, flexible power sources.

- Flexible electronics: Devices that bend or curve without breaking.

- Miniaturized systems: Medical devices, micro-robots, or sensors where every millimeter counts.

Simplified Construction and Scalability

Integrating electrode, connector, and support functions into a single material reduces complexity. This modular design simplifies assembly and enables scalable voltage stacking without added bulk of wiring and metal components.

Practical Demonstrations

This prototype supercapacitor can:

- Power 100 LEDs for about 30 seconds.

- Illuminate a 3-watt light bulb for 7 seconds.

These tests show it can reliably deliver power in real-world use cases despite its small size.

Durability and Environmental Resilience

Without metals that can corrode or add mechanical rigidity, this supercapacitor is well suited for harsh environments or applications with restricted space.

Comparison: Traditional vs. Metal-Free Graphene Supercapacitors

| Aspect | Traditional Supercapacitors | Metal-Free Graphene Supercapacitor |

|---|---|---|

| Materials | Metal current collectors and wires | Laser-induced graphene paper (no metals) |

| Thickness & Weight | Bulkier, heavier | Paper-thin, ultra-light |

| Voltage Output | Lower per volume | High: 200 volts in just 3.8 cm³ |

| Flexibility | Limited | Highly flexible and modular |

| Manufacturing | Complex wiring and assembly | Simpler laser fabrication and stacking |

| Environmental Impact | Uses metals, mining and disposal issues | More environmentally friendly, fewer materials |

Detailed Manufacturing Process: From Paper to 200 Volts

- Prepare Polyimide Paper:

Use a flexible commercial polyimide sheet as the starting substrate. - Laser-Induced Graphene Fabrication:

Expose the PI paper to a controlled CO₂ laser beam that converts designated areas into conductive 3D graphene. - Form Graphene Paper:

The LIG forms patterns that serve as electrodes and electrical conductors simultaneously. - Construct Thin-Film Supercapacitor Cells:

Each LIG region becomes a thin supercapacitor cell, just millimeters thick. - Apply Hydrogel Electrolyte:

Coat the cells with a hydrogel electrolyte layer that also functions as a separator. - Assemble the Stack:

Align and stack 160 cells carefully to achieve the desired voltage output. - Seal and Test:

Compress and seal the stack for performance testing, quality assurance, and eventual use.

Trilayer Graphene’s New Energy Effect: What It Is, Why It Matters, and Where It’s Headed

Could Trilayer Graphene’s Unusually High Kinetic Inductance Revolutionize Nanoelectronics?

Graphene Breakthrough Promises Faster, Smaller, More Efficient Electronics

FAQs About This Metal-Free Graphene Supercapacitor Generates 200 Volts

Q1: What makes graphene ideal for supercapacitors?

Graphene has a huge surface area (~2630 m²/g), excellent electrical conductivity, and strong mechanical flexibility. This enables high energy storage capacity and fast charge-discharge cycles essential for supercapacitors.

Q2: How do supercapacitors differ from batteries?

Supercapacitors store charge physically and can charge/discharge quickly with millions of cycles. Batteries rely on slower chemical reactions and have higher energy density but shorter lifespan in terms of charge cycles.

Q3: Why eliminate metals in supercapacitors?

Metals add weight, thickness, and limit flexibility. Removing them reduces cost, weight, ecological footprint, and enables flexible, thin form factors.

Q4: What current limitations exist for this technology?

Energy density (how much energy per unit volume/weight) and cycle life need improvement to match commercial batteries fully. Research is ongoing to enhance these parameters.

Q5: Is this technology commercially available now?

Currently, this is an advanced research prototype. Commercialization will require scaling up manufacturing and further improvements.

Looking Ahead: Future Potential

This metal-free graphene supercapacitor demonstrates a clear path toward flexible, light, high-voltage energy storage devices that can transform wearable gadgets, flexible electronics, and space-constrained systems. The use of laser-induced graphene to integrate multiple functions simplifies design and opens possibilities for customizable stacks tailored to specific voltage and size needs.

Ongoing research focuses on improving energy density, durability, and manufacturing techniques to bring this promising technology to market.