In the rapidly evolving world of clean transportation, hydrogen has long been viewed as a promising fuel of the future because it produces zero carbon emissions at the tailpipe. However, with the rise of battery electric vehicles (EVs), many have questioned whether hydrogen still has a viable role or if it is becoming obsolete. But a recent breakthrough from global engine leader Cummins Inc. challenges that notion. They have developed a hydrogen internal combustion engine (H2-ICE) that reduces carbon emissions by over 99% compared to today’s diesel trucks. Should we now see hydrogen as a dead technology, or is it just evolving?

Hydrogen combustion engines burn hydrogen just like traditional engines burn gasoline or diesel. Instead of emitting CO2 and harmful pollutants, hydrogen combustion mainly produces water vapor, making it an exceptionally clean alternative. Cummins’ new engine advances this concept by tackling two major hurdles hydrogen engines historically faced: performance and nitrogen oxide (NOx) emissions.

Table of Contents

This New Engine Cuts Emissions by 99%

| Key Highlights | Details & Stats |

|---|---|

| Engine Type | 6.7-Litre Hydrogen Internal Combustion Engine (H2-ICE) |

| Emissions Reduction | Over 99% reduction in carbon emissions compared to Euro VI diesel engines |

| Nitrogen Oxides (NOx) Emissions | Ultra-low levels achieved with advanced emission after-treatment |

| Target Vehicles | Medium-duty trucks, buses, with future plans for heavy-duty trucks and construction machinery |

| Collaboration Partners | Cummins Inc., Johnson Matthey, PHINIA, Zircotec, UK Government, Advanced Propulsion Centre UK |

| Investment & Development | £13 million invested in a new Powertrain Test Facility |

| Future Plans | Developing larger 15-litre version for heavy-duty vehicles |

| Official Source | Cummins Project Brunel Announcement |

Cummins’ new hydrogen internal combustion engine cutting emissions by over 99% signals an exciting advance in transport decarbonization. This technology shows hydrogen’s continued relevance and adaptability, especially in medium- and heavy-duty sectors where battery electric vehicles face challenges.

This engine blends the familiarity and durability of traditional combustion systems with state-of-the-art hydrogen fuel injection and emissions control, offering a promising path to cleaner transport. As governments push for stricter emissions standards and industries seek practical alternatives, hydrogen internal combustion engines stand as a powerful, complementary solution in the clean energy landscape.

What Is a Hydrogen Internal Combustion Engine?

To understand the significance of Cummins’ new engine, it helps to know how it works. A hydrogen internal combustion engine operates similarly to the gasoline or diesel engines we find in most vehicles today. Instead of burning fossil fuels, it combusts hydrogen gas inside its cylinders.

When hydrogen burns, it releases energy and produces mainly water vapor — no harmful carbon dioxide or other greenhouse gases typical of fossil fuel engines. However, hydrogen combustion can produce nitrogen oxides (NOx), pollutants formed from nitrogen and oxygen reacting at high temperatures. Reducing NOx emissions has been a major challenge.

Cummins’ engine uses advanced fuel injection technology and specialized emission after-treatment to cut NOx to ultra-low levels. The engine’s design is based on proven spark-ignited engine platforms, making it easier for manufacturers to adopt without completely redesigning their vehicles.

Why Is This Breakthrough Important?

Transportation remains one of the largest contributors to global carbon emissions, with road vehicles being a significant part of this. According to the International Energy Agency, road transport accounted for about 17% of global CO2 emissions in 2024.

In particular, medium- and heavy-duty vehicles, including trucks and buses, are harder to electrify fully with batteries due to their weight, energy needs, and long-distance operation. This is where hydrogen combustion engines can play a crucial role.

The advantages include:

- Fast refueling: Hydrogen pumps can fill a vehicle in minutes, just like diesel, unlike longer battery charging times.

- Long range: Hydrogen’s high energy density allows vehicles to travel further without increasing fuel tank weight excessively.

- Adaptability: Because the engine design builds on existing technology, vehicle makers can transition faster compared to completely switching to batteries or fuel cells.

Cummins demonstrated that their hydrogen engine delivers over 99% reduction in carbon emissions compared to modern diesel engines, combined with ultra-low NOx emissions — an environmental double win.

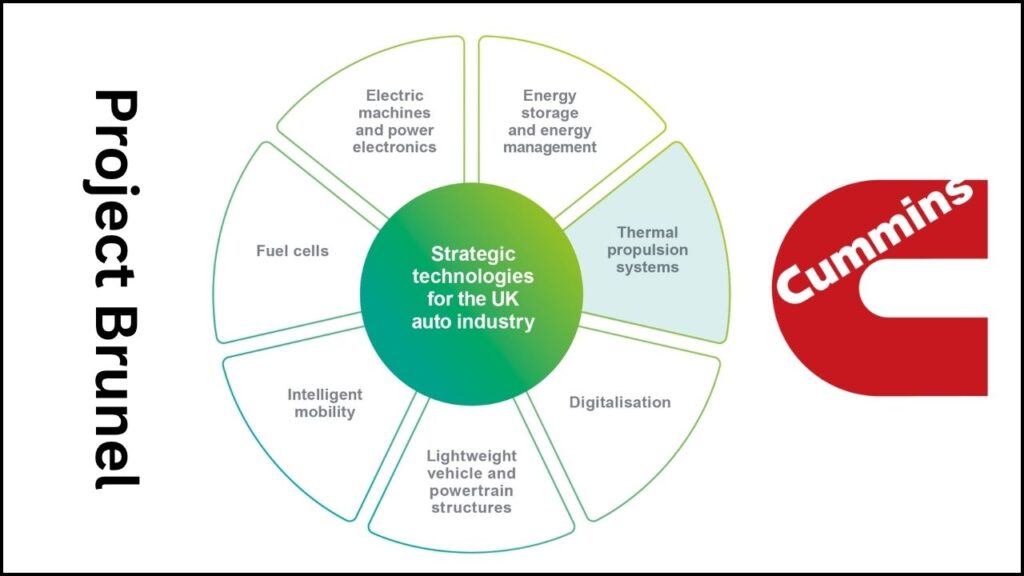

The Story Behind the Engine: Project Brunel

This major innovation comes from a collaborative effort named Project Brunel, which united Cummins with industry leaders Johnson Matthey (specialists in advanced materials and emissions control), PHINIA (hydrogen injection technology), and Zircotec (thermal coatings).

Backed by funding from the UK Government and the Advanced Propulsion Centre UK, the consortium developed the 6.7-litre hydrogen combustion engine tailored to medium-duty commercial vehicles like trucks and buses. The goal was to prove hydrogen combustion could meet performance, emissions, and durability standards required for real-world applications.

Project Brunel successfully demonstrated:

- A 6.7-litre hydrogen engine model with familiar engine mechanics but using zero-carbon hydrogen fuel.

- Over 99% reduction in carbon emissions compared to Euro VI diesel standards.

- Ultra-low nitrogen oxide emissions, meeting stringent environmental regulations.

- Strong performance and durability, ensuring commercial viability.

The project’s leaders expressed confidence that this technology could scale. Cummins is already working on a 15-litre version tailored for heavy-duty trucks, agricultural vehicles, and construction machinery — sectors where battery electric might be less practical due to weight and energy density constraints.

How Does This Compare To Other Clean Vehicle Technologies?

The clearest competitors to hydrogen combustion engines are hydrogen fuel cell vehicles and battery electric vehicles.

Hydrogen fuel cells use hydrogen to create electricity through a chemical reaction, which then powers electric motors. They offer zero tailpipe emissions, emitting only water vapor. However, fuel cells are technologically complex and expensive, requiring specialized stacks and durable materials.

Battery electric vehicles run entirely on electricity stored in batteries. They emit no pollution while running, but long charging times and battery weight limit their range and usefulness in heavy-duty and long-haul applications.

Here’s a simple comparison:

| Aspect | Hydrogen Combustion Engine | Hydrogen Fuel Cell Vehicle | Battery Electric Vehicle (EV) |

|---|---|---|---|

| Refueling Time | ~Minutes (similar to diesel) | ~Minutes (hydrogen stations) | 30 minutes to hours (charging) |

| Vehicle Range | Long range possible | Long range possible | Limited by battery size and weight |

| Vehicle Complexity | Low to Medium | High | Medium (battery technology) |

| Infrastructure Availability | Limited but growing | Limited but growing | Widely expanding globally |

| Emissions | Near zero CO2, ultra-low NOx | Zero tailpipe emissions | Zero tailpipe emissions |

Each technology fits different needs. Hydrogen combustion engines could be especially useful where fast refueling and heavier payloads matter most.

Practical Advice For Fleet Operators and Businesses

If you operate or manage fleets with medium- to heavy-duty trucks or buses, here are practical considerations:

- Evaluate duty cycles: Vehicles traveling long distances or carrying heavy loads benefit from hydrogen combustion engines’ fast refueling and lighter fuel weight.

- Assess local hydrogen infrastructure: Consider availability of hydrogen fueling stations and government support for hydrogen transport. This can impact adoption ease.

- Align with regulations: Governments are tightening emissions requirements globally. Hydrogen combustion engines offer a pathway to comply without the costs of full electrification in the near term.

- Engagement: Stay connected with manufacturers like Cummins developing these solutions and explore opportunities to pilot hydrogen engines as they enter commercial use.

This approach allows fleets to reduce emissions drastically while moving toward sustainable, zero-carbon operations.

Breakthrough Turns Sugarcane Waste Into Clean Hydrogen — With Almost Zero Emissions

New Triple-Layer Catalyst Boosts Green Hydrogen Output by 800%—A Game-Changer for Clean Energy

FAQs About This New Engine Cuts Emissions by 99%

Q1: Is hydrogen fuel safe for vehicles?

Yes. Modern hydrogen storage and fueling systems comply with rigorous safety standards. Tanks are designed to withstand impacts and pressure, with multiple fail-safes.

Q2: How costly is a hydrogen combustion engine compared to diesel?

Currently, costs are higher due to new technologies and materials, but prices are expected to fall as production scales and technologies mature.

Q3: Will hydrogen combustion engines replace electric vehicles?

Not completely. They complement battery electric and hydrogen fuel cell vehicles, particularly in sectors where battery limitations affect usability.

Q4: Where is hydrogen fuel infrastructure available?

Mainly in regions like Europe, Japan, South Korea, and parts of the US. Infrastructure is expanding steadily, especially for commercial vehicle corridors.

Q5: What about environmental impact beyond emissions?

Hydrogen production’s source matters. “Green” hydrogen produced via renewable energy maximizes environmental benefits, while hydrogen from fossil fuels (“grey” hydrogen) reduces advantages.