Discovering new polymer materials that can transform industries—from medicine to energy—is no easy task. With nearly limitless possible polymer combinations and complex interactions, finding the perfect blend can feel like searching for a needle in a haystack. But a new autonomous system developed by researchers at MIT promises to change this game. This breakthrough technology efficiently explores and identifies optimal polymer blends faster than ever, opening the door to materials with unprecedented performance and potential.

Table of Contents

Unlocking the Future of Polymer Discovery

Polymers—large molecules made of repeated units—are vital in countless products, from plastics and coatings to batteries and bioengineering. Traditionally, scientists searched for new polymers by trial and error or by focusing on individual polymer components. However, this approach is slow, costly, and limited because many promising blends might be overlooked if the focus stays only on the best single polymers.

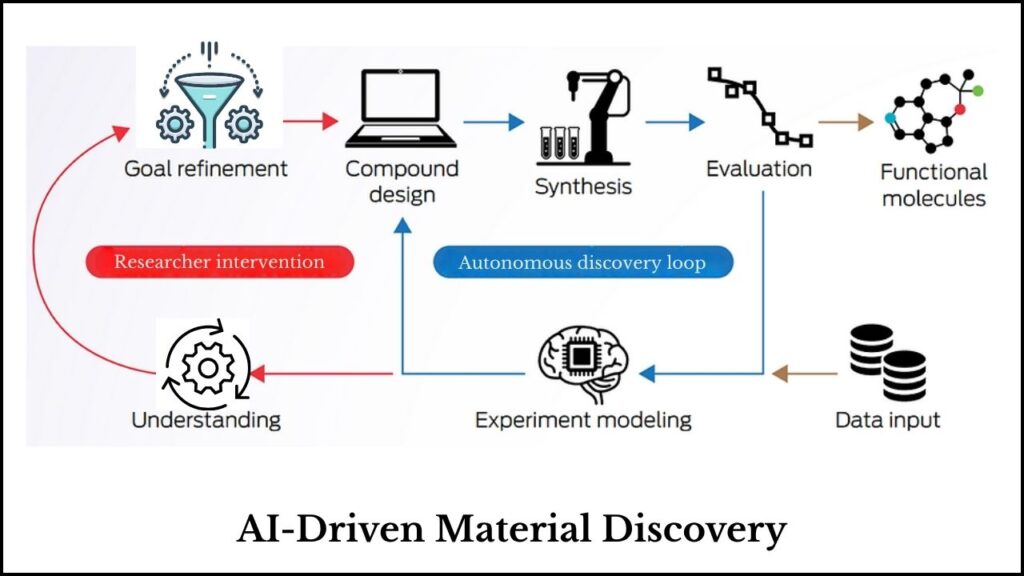

Addressing these challenges, MIT researchers have created a fully autonomous experimental platform that blends artificial intelligence (AI), robotics, and high-throughput testing. The system uses an iterative, closed-loop process where:

- An AI algorithm selects promising polymer blend candidates based on desired properties.

- A robotic system autonomously mixes and tests up to 700 polymer blends per day.

- Test results feed back into the algorithm to refine and guide the next round of experiments.

This cycle repeats until the optimal polymer blend is found, dramatically cutting down the time and effort required compared to conventional methods.

This New System Could Revolutionize How We Discover Polymer Materials

| Aspect | Details |

|---|---|

| System Type | Fully autonomous experimental platform combining AI, robotics, and automation |

| Daily Throughput | Up to 700 new polymer blends tested |

| Optimization Technique | Genetic algorithm—biologically inspired method improving polymer composition iteratively |

| Performance Improvement | Optimal blends outperform individual polymers by up to 18% in thermal stability tests |

| Applications | Protein stabilization, battery electrolytes, new plastics, and more |

| Lead Researcher | Connor Coley, MIT Assistant Professor of Chemical Engineering and Computer Science |

| Official Reference | MIT News: New system dramatically speeds the search for polymer materials |

The new autonomous system developed by MIT represents a revolutionary leap in polymer materials discovery. By combining AI, robotics, and high-throughput testing in a smart closed-loop platform, it efficiently explores the vast polymer formulation universe—finding optimal blends faster, cheaper, and more effectively than ever before.

This technology promises to accelerate innovations in materials critical for health, energy, sustainability, and beyond, opening new frontiers in science and industry. Its success demonstrates the transformative potential of integrating artificial intelligence with experimental science.

The Challenge: A Vast Polymer Universe

Imagine trying to find a recipe that uses many different ingredients where the way the ingredients combine changes the taste completely. Now multiply that complexity by thousands—or even millions—of possible ingredient blends. That’s the problem with polymers. Scientists know that blending polymers can yield materials with better or entirely new properties, but predicting the right blend is incredibly challenging due to:

- Nearly infinite combinations: Thousands of polymers can be combined in countless ways.

- Complex interactions: Polymer properties don’t simply add up; components can interact unpredictably.

- Resource constraints: Testing every blend manually is impractical and time-consuming.

This complexity traditionally meant researchers either stuck with known blends or spent years on painstaking trial-and-error testing.

How the Autonomous Platform Works

The MIT system overcomes these hurdles using automation and smart algorithms:

1. AI-Driven Blend Selection

A genetic algorithm begins the process by digitally encoding each polymer blend as a “chromosome.” Drawing inspiration from biological evolution, the algorithm applies selection, mutation, and crossover operations to iteratively improve blend combinations toward desired properties, such as thermal stability or enzymatic activity retention.

Unlike some predictive models that struggled with accuracy due to the size of the polymer design space, this approach dynamically balances exploration of new possibilities with exploitation of known promising candidates.

2. Robotic Mixing and Testing

Once the AI selects potential blends, a robotic system autonomously prepares 96 blends at a time. It mixes the polymers and performs tests to measure critical properties—like how well enzymes remain active after heat exposure or the blend’s stability.

3. Closed-Loop Feedback for Continuous Learning

The experimental results are instantly fed back to the AI algorithm. This information helps it adjust the next batch of polymer blends to test, steadily honing in on the optimal combination. Human scientists oversee the process but intervene only occasionally to replenish materials or troubleshoot.

Real-World Success: Outperforming Expectations

During initial trials focusing on improving thermal stability of enzymes mixed with polymer blends (important for biological applications), the system autonomously discovered hundreds of blends that outperformed their individual polymer components.

The best blend performed 18% better than any single polymer in terms of retained enzymatic activity after heat treatment—demonstrating that the right combination can unlock new material capabilities previously unseen by focusing on components alone.

“Considering the full formulation space simultaneously enables discovery of new or better properties that could be easily overlooked,” explained Connor Coley, the lead researcher.

Practical Implications: Why This Matters

This autonomous system isn’t just a laboratory curiosity—it has vast potential to impact industries and society by:

- Speeding up materials discovery: What used to take months or years can now be done in days, accelerating innovation cycles.

- Reducing R&D costs: Automating experiments lowers labor needs and material waste.

- Enabling sustainability: Efficient polymer blends can create better biodegradable plastics, improve energy storage, or stabilize proteins for greener pharmaceuticals.

- Unlocking complex formulations: Capturing the full complexity of polymer interactions can lead to better-performing products in medicine, electronics, textiles, and more.

Expanding Horizons: Future Prospects and Adaptations

While the current focus has been on polymer blends, the principles behind this platform hold promise for accelerating discovery in other material sciences. The integration of AI-driven optimization and robotics could aid in developing new pharmaceuticals, catalysts, battery electrolytes, and other advanced materials.

Researchers are continuously enhancing the algorithms to handle even larger design spaces and integrating more advanced sensing technologies for richer data capture. Efforts are underway to create modular autonomous labs where experiments requiring different techniques can be conducted seamlessly under AI supervision.

A Step-by-Step Guide to Autonomous Polymer Discovery

For companies or researchers interested in leveraging similar technology, here’s an easy-to-follow overview of how such a platform functions:

Step 1: Define Material Goals

Specify what properties the new polymer blend should have, such as mechanical strength, thermal stability, conductivity, or enzyme compatibility.

Step 2: Initialize Algorithm

Start the genetic algorithm with a selection of existing polymers encoded as digital “chromosomes.”

Step 3: Generate Blend Candidates

The algorithm produces a set of candidate polymer blends, balancing novelty and promising features.

Step 4: Robotic Synthesis and Testing

The robotic system mixes each blend autonomously and tests physical and chemical properties rapidly.

Step 5: Data Feedback and Learning

Test results feed back to the algorithm, which learns and updates its predictions to generate better blends next.

Step 6: Iterate Until Optimal Blend Found

Repeat steps 3-5 in a closed-loop until blends meeting or exceeding target specifications are identified.

Safer Batteries May Be on the Horizon With Next-Generation Polymer Blends

New Gel Polymer Mimics Muscle and Gains Strength With an Innovative Formula

New Polymer Fiber Breakthrough Releases Antibacterial Drugs Only When Needed

FAQs About This New System Could Revolutionize How We Discover Polymer Materials

Q1: What is a polymer blend?

A polymer blend is a mixture of two or more different polymers combined to create a material with new or enhanced properties compared to individual polymers.

Q2: How does a genetic algorithm work in this context?

It mimics natural selection by iteratively selecting, modifying, and recombining polymer blends to discover those best meeting material goals.

Q3: Why use robotics?

Robotics enable rapid, consistent preparation and testing of numerous blends without human fatigue or error, vastly speeding up experiments.

Q4: Can this system be used for other material types?

Yes, while initially tested for polymers, the approach could be adapted for discovering catalysts, pharmaceuticals, battery materials, and more.

Q5: Are humans still involved?

Humans define goals, supply materials, and manage exceptions; the system handles most experimentation autonomously.

Q6: How does this technology promote sustainability?

By enabling efficient discovery of polymer blends that improve biodegradability or stabilize biologically important molecules, this system helps develop greener materials and reduces environmental impact.