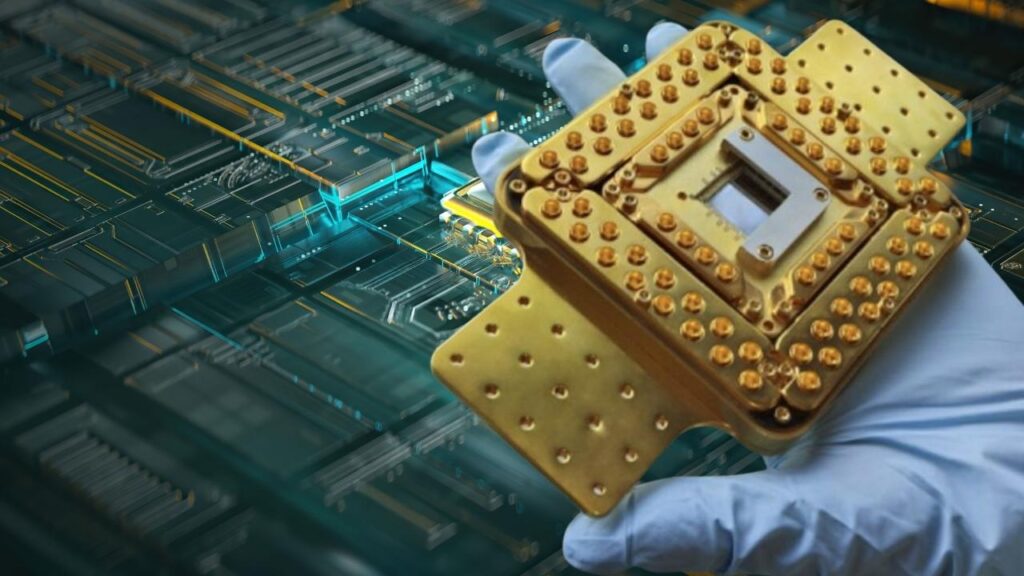

Russian Scientists Create Ultra‑Precise Sub‑Ångström Tech for Quantum Chips of Tomorrow: Russian scientists at Bauman Moscow State Technical University and VNIIA have developed a cutting-edge breakthrough known as iDEA—Ion beam–induced DEfects Activation—that fine-tunes quantum chip components with an extraordinary ±0.2 ångström precision. That’s finer than the width of a hydrogen atom, allowing unprecedented accuracy in adjusting superconducting qubits for next-gen quantum processors.

Whether you’re just curious or deep in semiconductor R&D, this is a game-changing leap forward. Imagine a world where every quantum bit (qubit) is tuned perfectly, delivering stable, repeatable performance. That’s exactly what iDEA is promising.

Russian Scientists Create Ultra‑Precise Sub‑Ångström Tech for Quantum Chips of Tomorrow

| Feature | Details & Stats |

|---|---|

| Name | iDEA – Ion beam–induced DEfects Activation |

| Precision | ±0.2 Å sub‑ångström control |

| Tunnel Dielectric | Tuned layers from 0.8–2 nm |

| Tuning Speed | ~1 second per qubit |

| Frequency Variation | <±0.35% (~±17 MHz) |

| Coherence Time | Greater than 500 µs |

| Chip Yield | Near 100% on 1,000+ qubit arrays |

| Publication | Science Advances |

| Patent | Russian patent granted; global filing pending |

| Source Link | The Quantum Insider |

Russia’s iDEA breakthrough marks a major turning point in the evolution of quantum chip manufacturing. By controlling oxide layer thickness at the atomic level, researchers have solved one of the biggest bottlenecks in superconducting qubit design: consistency. If adopted globally, this tech could power larger, more stable, and error-resistant quantum computers—ushering in a new era of computing capability.

What’s Sub‑Ångström Tech—and Why Does It Matter?

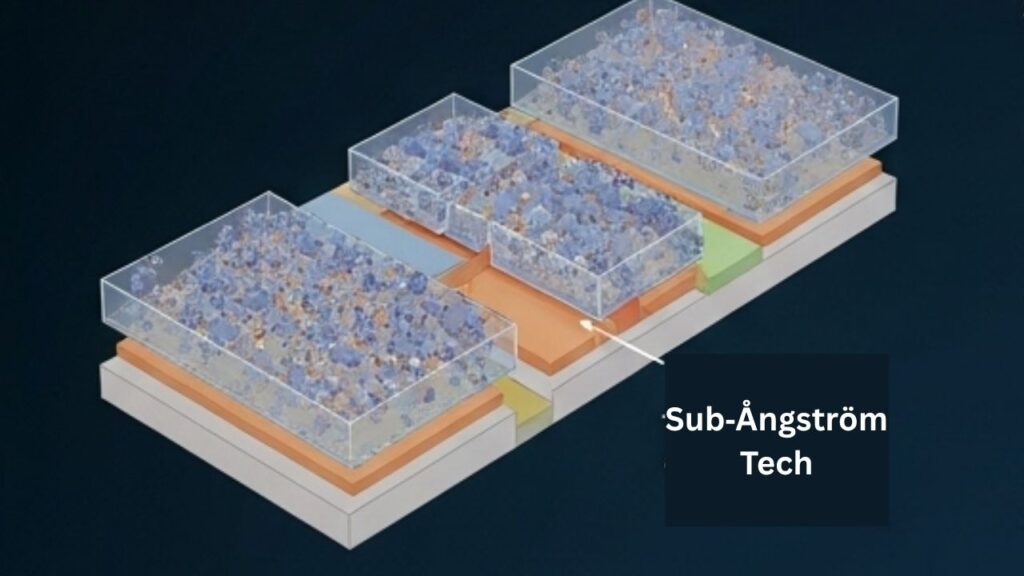

An ångström (Å) is one ten-billionth of a meter—0.1 nanometers. It’s the unit scientists use when dealing with atomic layers. Achieving ±0.2 Å precision means Russian engineers can tweak the atomic structure of materials to within just a couple of atoms.

Superconducting qubits, like those in IBM and Google chips, use what’s called a Josephson junction—a super-thin insulator between two superconductors. If the insulating layer’s even a tiny bit off, the qubit acts out. That ruins frequency uniformity, makes systems harder to calibrate, and lowers chip performance.

With iDEA, these inconsistencies vanish. Russian researchers are tuning each junction’s oxide thickness after fabrication to lock every qubit into a narrow operating range.

How iDEA Works: A Step‑by‑Step Breakdown

- Fabricate superconducting qubits using standard processes, including aluminum electrodes and thin aluminum oxide junctions.

- Scan each junction with a focused helium or neon ion beam.

- Inject lattice defects in the oxide layer, causing subtle atomic changes.

- Tweak junction thickness at atomic scale to control tunneling resistance.

- Confirm with testing that resistance and frequency meet ideal specs.

- Repeat for each qubit—takes about 1 second per unit.

This method boosts the precision of Josephson junctions from a typical ±2 Å tolerance (in standard CMOS processes) down to ±0.2 Å.

Why This Is a Big Deal Globally

- Chip Yields: Conventional superconducting chips often run into fabrication variability past 300–400 qubits. iDEA demonstrates near-perfect performance across 1,000+ qubits.

- Uniform Frequencies: Deviations of less than ±17 MHz make error correction and control logic simpler, slashing overhead in quantum control systems.

- Coherence Time: Devices tuned with iDEA maintain coherence for over 500 microseconds, comparable with top-tier hardware from companies like IBM and Google.

- Speed and Safety: Unlike electron or laser tuning, ion beams offer fast, localized control without significant risk of damaging other parts of the chip.

Real‑World Testing and Results

Researchers combined molecular dynamics (MD) simulations with lab experiments to fine-tune tunnel barriers. Here’s what they found:

- Resistance can be varied in a controlled and repeatable way between +2% and +37% by adjusting ion dose.

- Uniformity across a 1,000+ qubit array was within ±0.86% deviation—a huge improvement over traditional junction spreads.

- Chips using iDEA passed real-world materials science benchmarks, showing no loss of fidelity due to ion tuning.

These results were published in Science Advances, a peer-reviewed, high-impact journal. Their MD simulations show how ion interactions at the atomic level influence oxide thickness, which directly affects the qubit’s critical current and frequency.

Practical Applications and Advice for Engineers

If you’re in quantum tech, chip design, or nanoengineering, this method has immediate value. Here’s how different roles can make use of iDEA:

For Fabrication Teams

- Add iDEA as a post-fab precision step to improve chip yields.

- Use standard focused ion beam (FIB) equipment, already in many semiconductor labs.

For Quality Control Engineers

- Monitor resistance tuning in real time with in-situ measurements.

- Improve chip validation workflows by narrowing acceptable variance.

For Quantum Architects

- Design larger systems without worrying about frequency overlaps.

- Reduce the burden on quantum control software by standardizing qubit behavior.

For Students and Researchers

- Study ion beam interactions with atomic lattices.

- Explore future uses in other emerging fields like memristors and neuromorphic computing.

Trusted Sources and Further Reading

- The Quantum Insider article on iDEA

- Science Advances: “Angstrom-scale ion-beam engineering of buried ultrathin oxides” (2025)

- Nature Review on superconducting qubits

- NIST Quantum Computing Standards

Meta Launches New AGI Lab to Dominate the Future of Artificial Intelligence

Scientists Uncover Bumblebee Colony’s Secret Pause Strategy That Changes Everything

Fugaku Remains the World’s Graph King — Still #1 in Global Supercomputing Rankings

FAQs About Russian Scientists Create Ultra‑Precise Sub‑Ångström Tech for Quantum Chips of Tomorrow

1. What’s so special about ±0.2 Å control?

It means engineers can control layer thickness at the atomic level—about one-fifth the width of a hydrogen atom. That’s ultra-precise.

2. What’s a Josephson junction?

It’s a key element in superconducting qubits, made of two superconductors separated by an ultrathin insulator. Its thickness controls qubit properties.

3. Will this be used in commercial chips soon?

The technology is still being explored but is patented in Russia. Global adoption could follow if licensing agreements or open-source frameworks emerge.

4. How does this compare to U.S. and EU efforts?

IBM and Google lead with over 1000-qubit devices, but iDEA’s precision control offers a potential edge in yield and coherence uniformity.

5. Can iDEA be used in other chip types?

Yes. The same ion beam tuning could improve memristors, spintronics, and post-CMOS devices that rely on ultrathin oxide layers.